Photoelectric detector for 650nm optical fiber communication and its producing method

A photodetector and optical fiber communication technology, applied in the field of photodetectors, can solve the problems of reduced minority carrier diffusion length and low short-wave photoresponsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

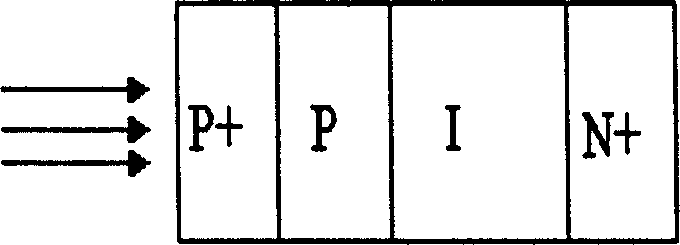

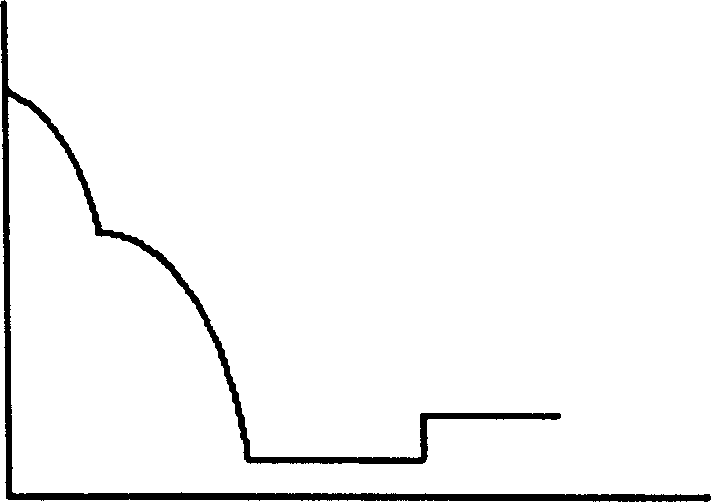

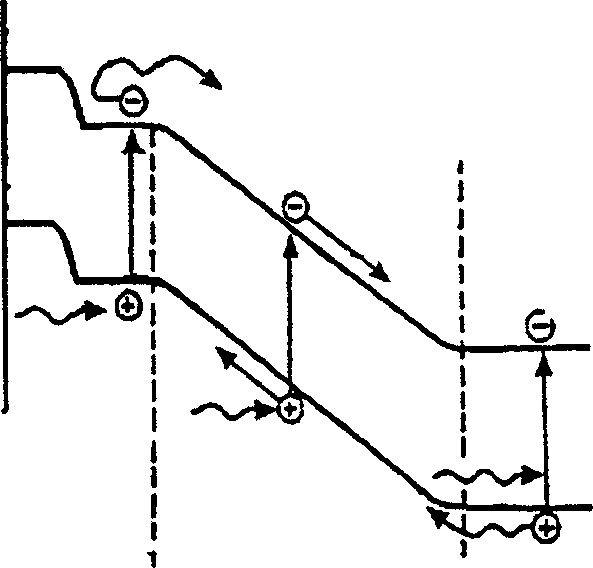

[0049] see figure 1 , the photodetector used for 650nm optical fiber communication is heavily doped P + Surface layer / P-type layer / Low-doped N - type epitaxial layer / heavily doped N + Substrate layer, namely P + / P / I(N - ) / N + Four layers of structure. After the P of the above structure + -P-I-N + The theoretical numerical simulation of the absolute spectral responsivity of silicon photodetectors with high and low emission junctions determines the vertical structure parameters of the device as:

[0050] P + The thickness of the zone is 0.1 μm and the concentration is 1×10 20 cm -3 , the thickness of the P region is 0.8 μm, and the concentration is 1×10 21 cm -3 , the thickness of I region is 200μm, N + The thickness of the zone is 0.5 μm and the concentration is 1×10 20 cm -3 , SiO 2 The film has a refractive index of 1.5 on SiO 2 The thickness of the film is 0.108 μm or 0.325 μm and the transmittance is 0.95%.

[0051] The parameters of the epitaxial wafer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com