Multi-tank type rotating digging turnover mixing apparatus

A kind of mixing and trough-type technology, which is applied in fertilization equipment, bio-organic part treatment, agriculture, etc., can solve the problems of unripe livestock and poultry manure, large capital investment, low mixing efficiency, etc., and achieve stable composting quality, Material fermentation heats up quickly and changes the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

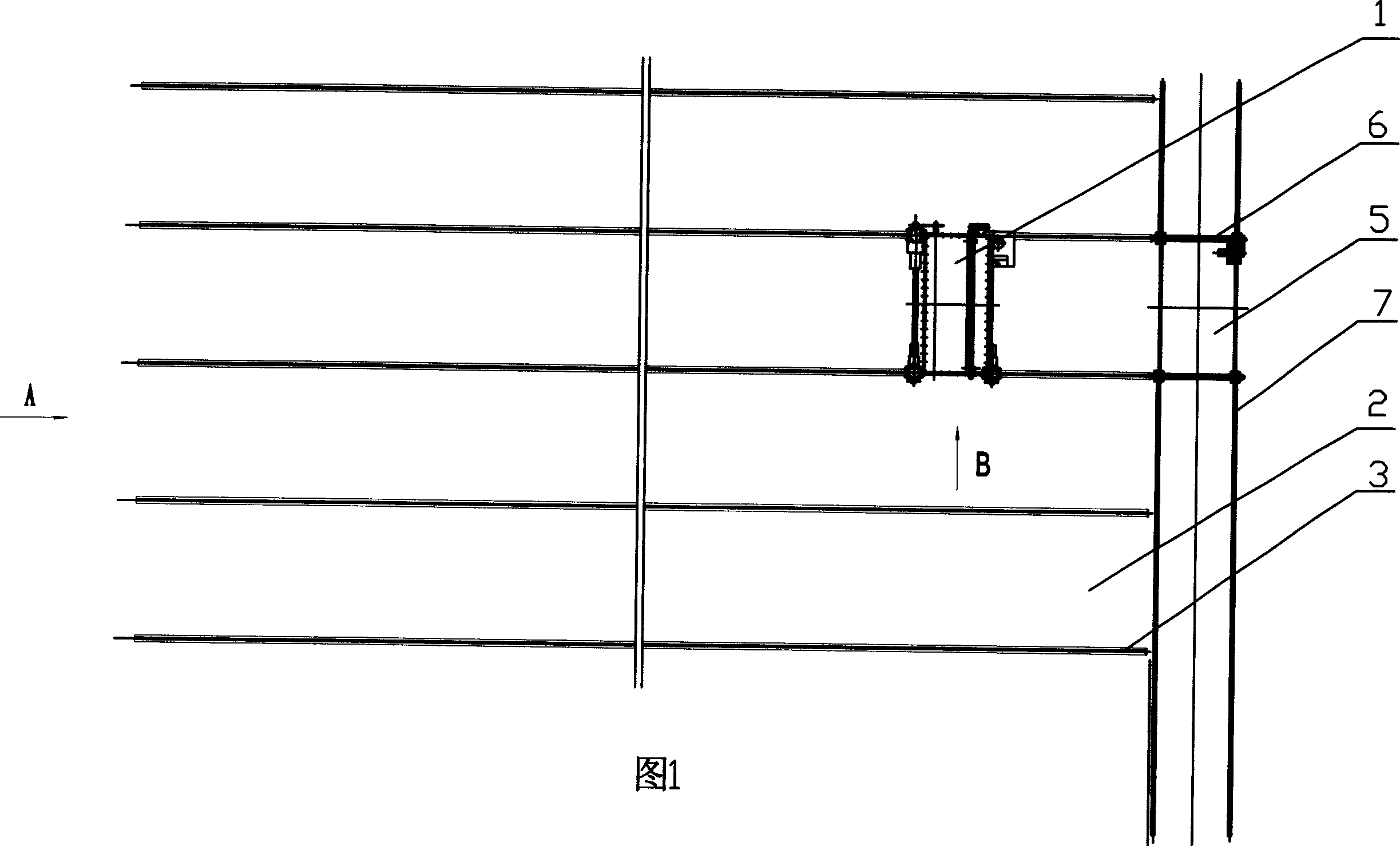

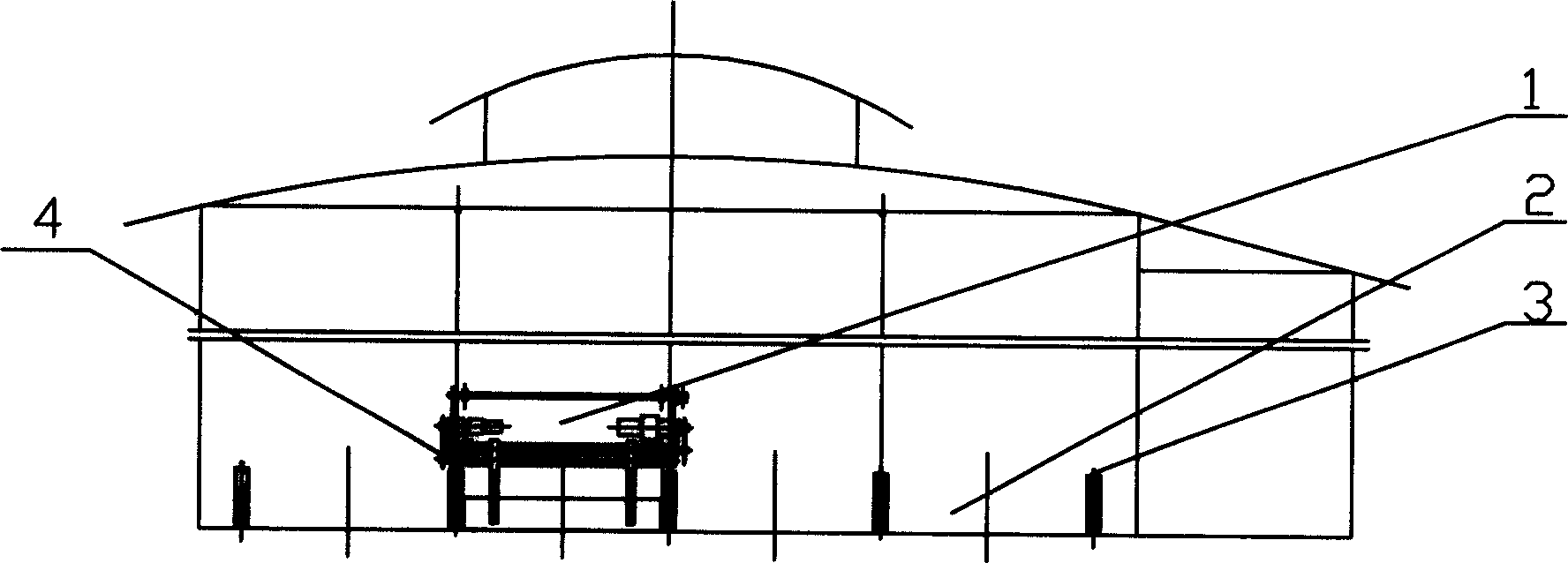

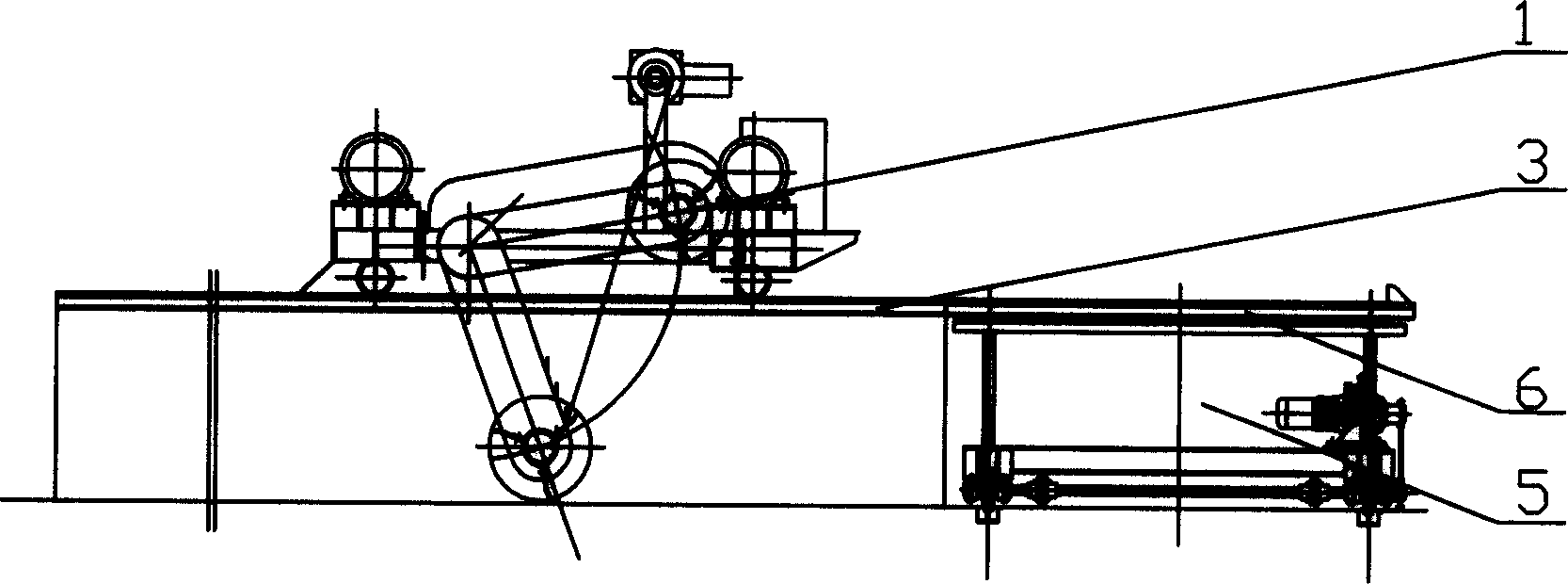

[0024] The present invention will be further described below in conjunction with embodiment. This multi-groove rotary digging and mixing device mainly includes a turning and mixing machine 1, which is provided with a group of equivalent compost fermentation tanks 2, and the end surface of the compost fermentation tank 2 is provided with parallel working tank tracks 3, and the turning and mixing machine 1 passes through it. The bottom roller 4 is installed on the working groove track 3 and cooperates with the working groove track 3 in a rolling manner. The mixing machine 1 mainly includes a frame, a traveling transmission device, a mixing device 24, a lifting device 25 and an electric control box 26. The electric control box 26 is installed on the frame, and the frame is connected to the traveling reduction motor 10 through the traveling transmission device. Connect and be installed on the opposite side of the mixing motor on the frame, and the frame is provided with an operato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com