Preparation process for gas phase corosion inhibitor of morpholine adrivative

A technology of gas-phase corrosion inhibitor and morpholine derivatives, which is applied in the hydrocarbon-based field, can solve the problems of inconvenient use, and achieve the effect of fewer steps, lower requirements, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 1 mol of morpholine, mix it with 1.2 mol ~ 1.5 mol of diisopropylamine, dropwise add 1 mol ~ 1.5 mol of formaldehyde solution, add 1.5 mol of benzoic acid to the above mixture, and add 50ml ~ 80ml of deionized water at the same time, Stir for 2 hours to 4 hours, and filter to obtain 150 g of solid powder, which is the vapor phase corrosion inhibitor of morpholine derivatives, called corrosion inhibitor 1.

Embodiment 2

[0018] Take 1mol of morpholine, mix it with 1.2mol~1.5mol of di-n-butylamine evenly, add dropwise 1mol~1.5mol of formaldehyde solution, add 1.5mol of salicylic acid to the above mixture, and add 50ml~80ml of deionized water, stirred for 2 hours to 4 hours, and filtered to obtain 130 g of solid powder, which is the vapor phase corrosion inhibitor of morpholine derivatives, called corrosion inhibitor 2.

Embodiment 3

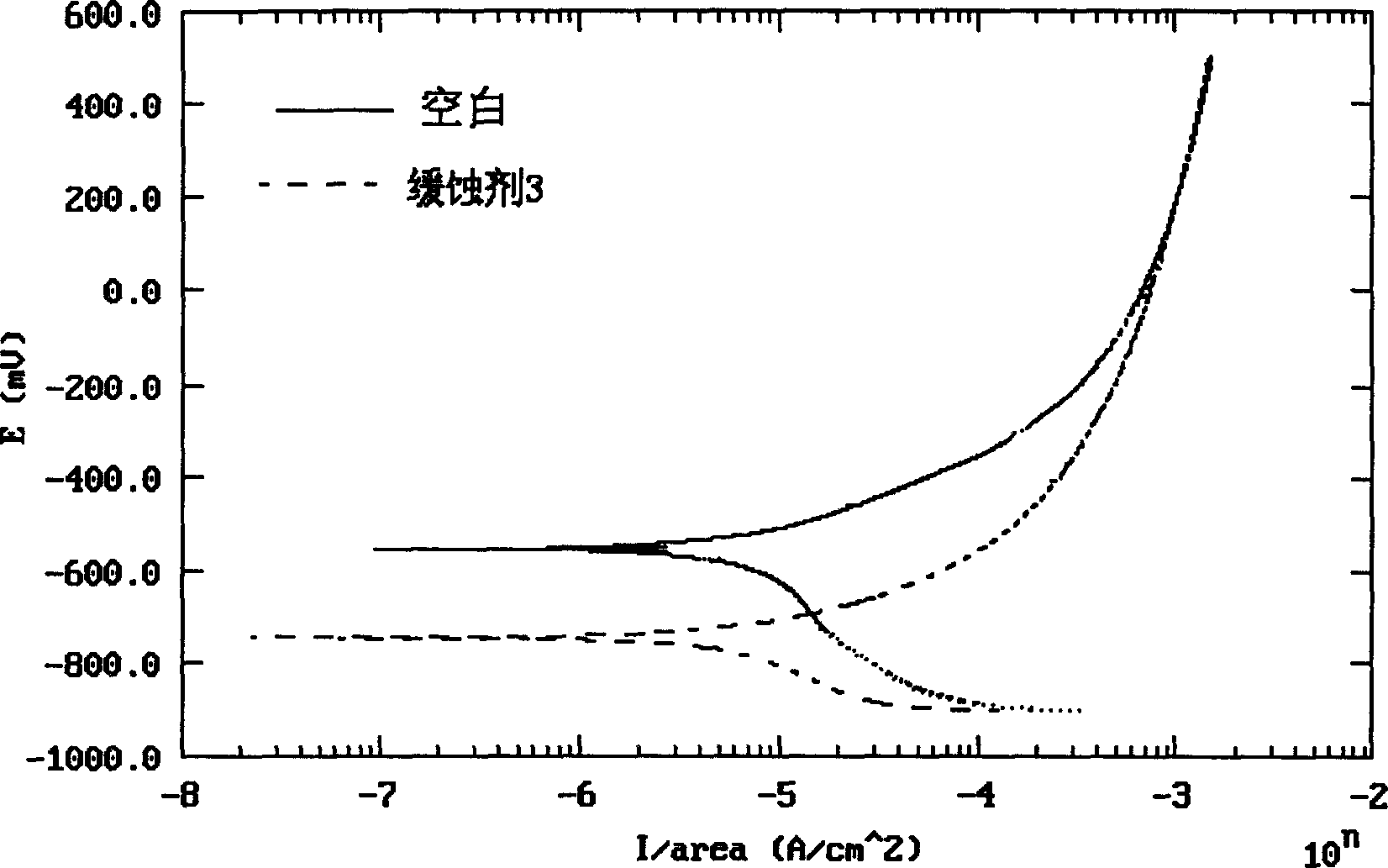

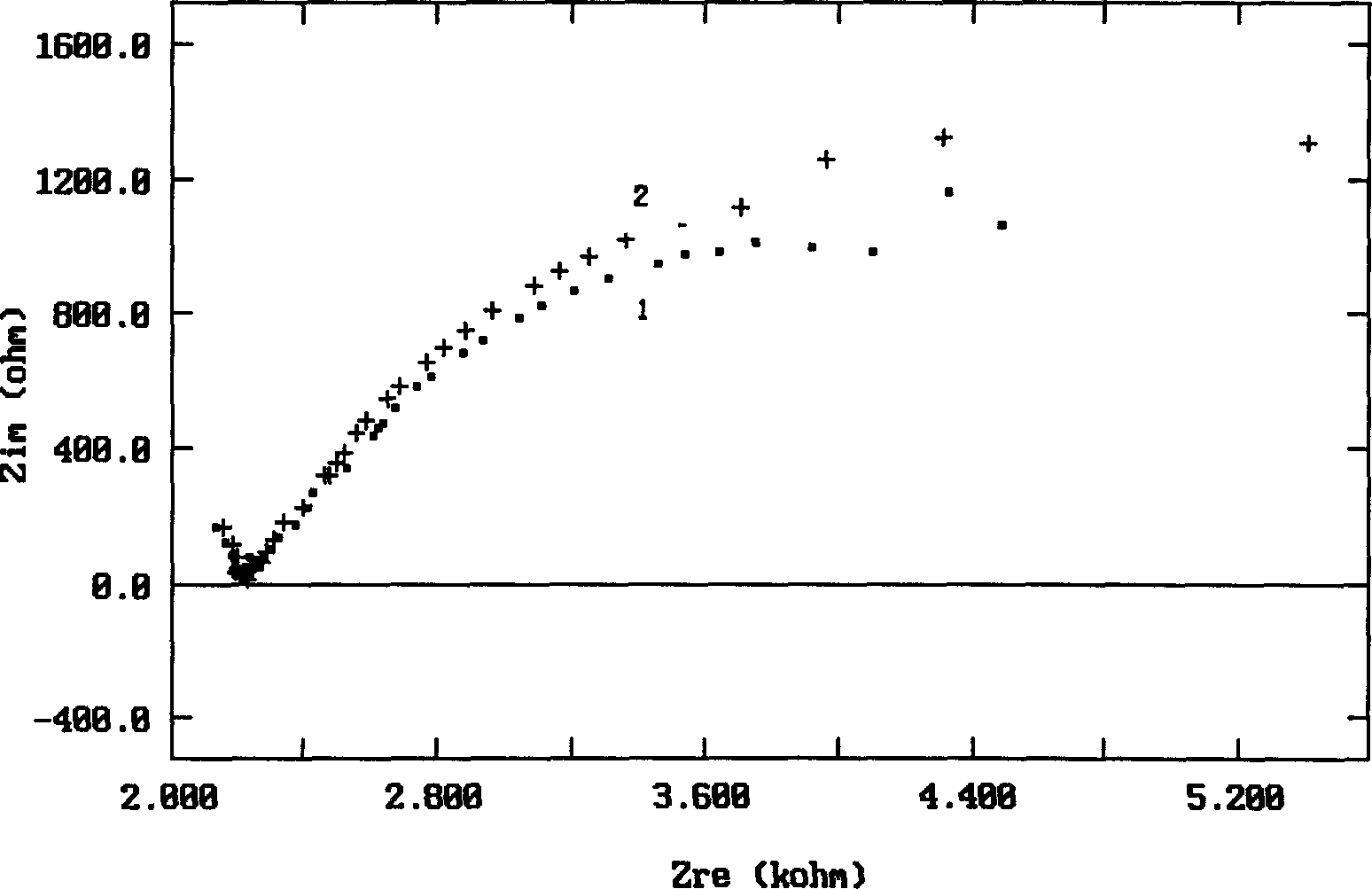

[0020] Take 1mol of morpholine, mix it with 1mol~1.5mol of dicyclohexylamine evenly, add dropwise 1mol~1.5mol of formaldehyde solution, add 1.5mol of benzoic acid to the above mixture, and add 50ml~80ml of deionized water at the same time, Stir for 2 hours to 4 hours, and filter to obtain 140 g of solid powder, which is the vapor phase corrosion inhibitor of morpholine derivatives, called corrosion inhibitor 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com