Secondary lithium cell using sulfurized crosslinking PVC as cathode material

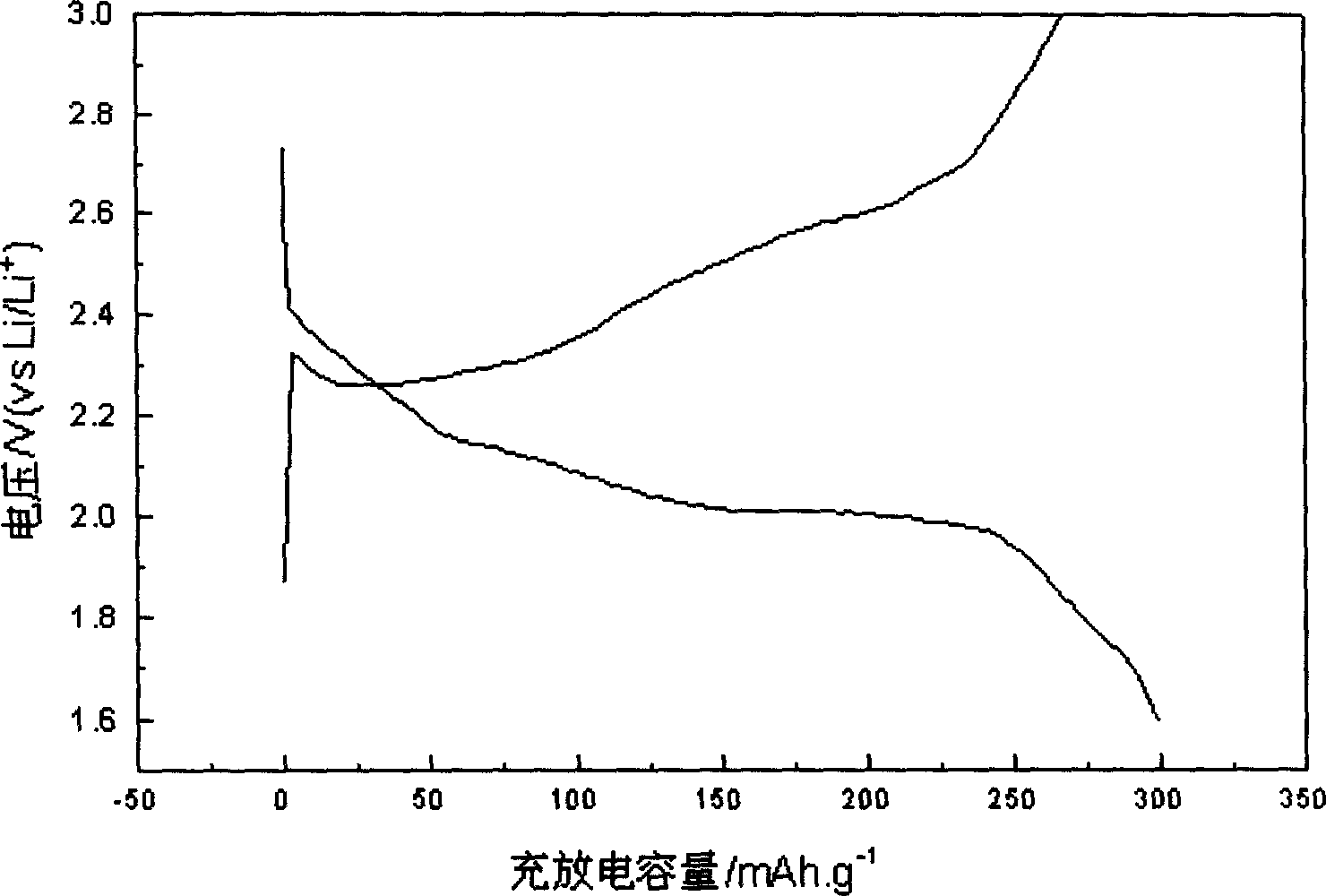

A secondary lithium battery and polyvinyl chloride technology, which is applied in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of complex synthesis process, environmental pollution, and great impact on the environment and equipment, and achieve low preparation cost, Good charge-discharge cycle performance and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Preparation of a secondary lithium battery using tetrathio-crosslinked polyvinyl chloride as the cathode material:

[0022] 1. Cathodic Material Synthesis

[0023] Weigh 7.88g of anhydrous sodium sulfide (99%) and 9.70g of sublimed sulfur (99%) and mix them and place them in 70ml of N, N-dimethylformamide solvent, stir at room temperature for 1 hour and raise the reaction temperature to 62 ℃ and continue to stir for 12 hours, stop stirring and keep the temperature for later use.

[0024] Weigh 12.51g polyvinyl chloride (Mw=2×10 5 ) and dissolved in 300ml N, N-dimethylformamide solvent to obtain a transparent and clear solution, after which this solution was stirred at 80°C and the above-mentioned standby sodium polysulfide solution was added dropwise, the dropping process continued for 1 hour, and the dropping After the addition, the stirring was continued at 96° C. for 18 hours, a brownish-red precipitate appeared in the system, and the reaction was complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com