Field emission display made by single grid structure and silver pasting method

A technology of structure field and grid structure, which is applied in the direction of image/graphic display tube, cold cathode manufacturing, electrode system manufacturing, etc. It can solve the problem of contamination or damage on the surface of the film layer, high electrical requirements and manufacturing requirements, and grid structure manufacturing. Complicated process and other issues, to achieve the effect of perfect packaging, low cost, avoiding pollution and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to this embodiment.

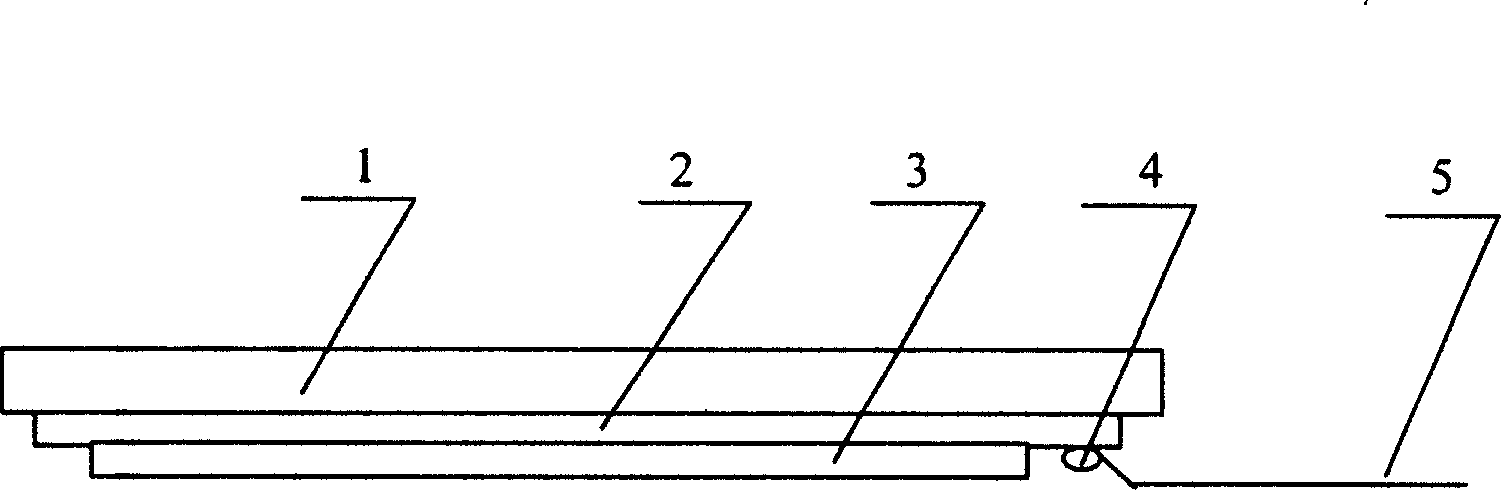

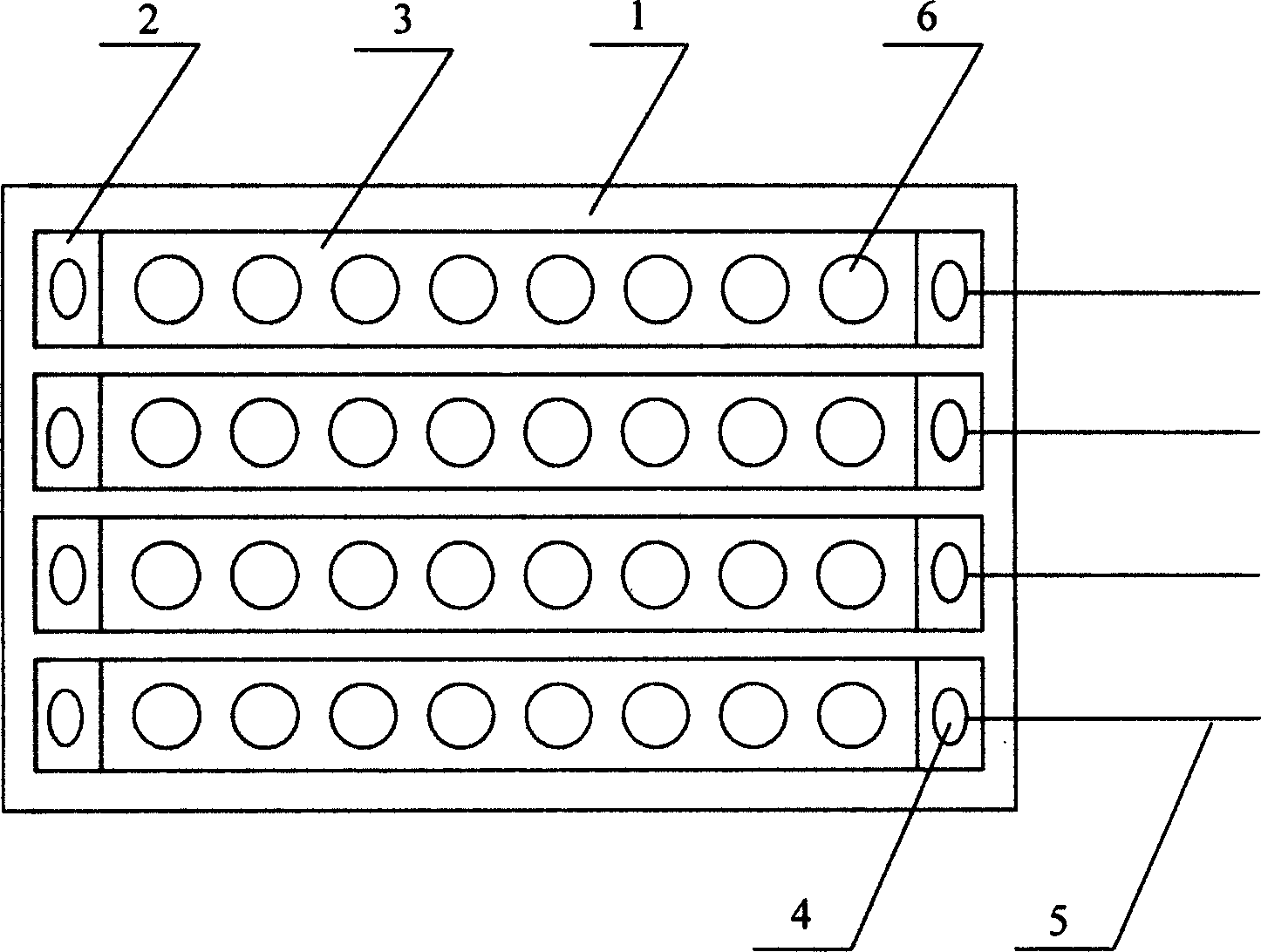

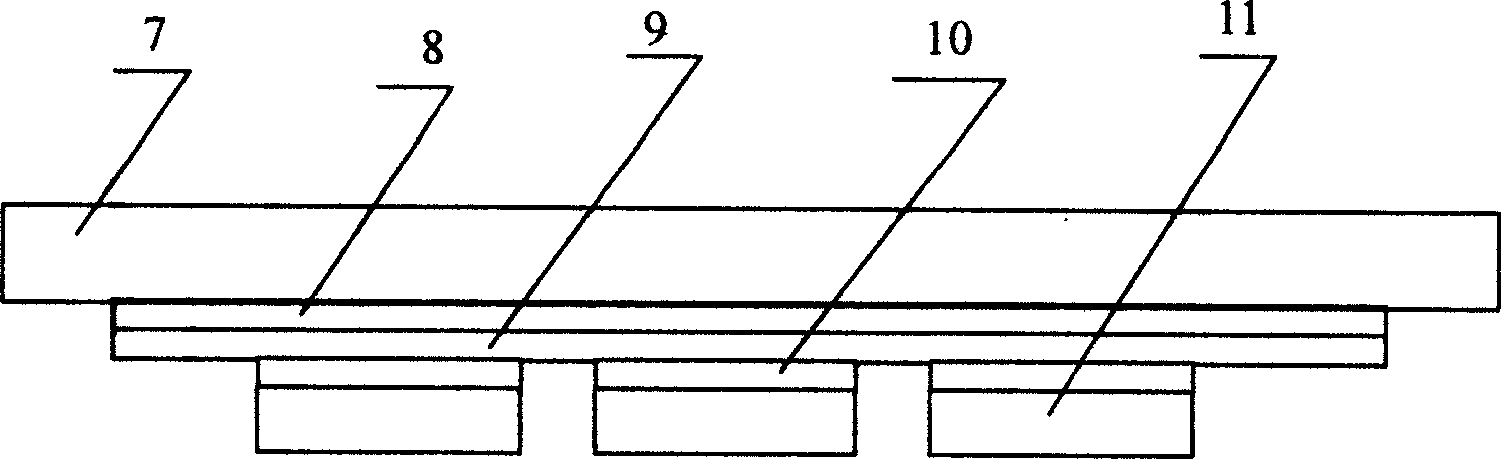

[0033] The three-pole field emission display of the present invention forms a sealed vacuum chamber by an anode panel 20, a cathode panel 12 and surrounding glass enclosures 13; photoetching forms an indium tin oxide transparent conductive film (Indium Tin Oxide, ITO) on the anode panel 12 18 conductive strips, printed on the ITO strip to form a phosphor layer 17; making isolation pillars 14 between the anode panel 12 and the control grid structure; using the substrate material 1 of the single grid, printed on the single grid substrate The silver paste layer on the material 1 and the insulating paste layer printed on the silver paste layer are used to form a single grid structure; the cathode lead wire arranged on the cathode panel and the cathode plate silver paste paste and fixation technolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com