Semiconductor device and producing method thereof

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as poor production capacity and time required for formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

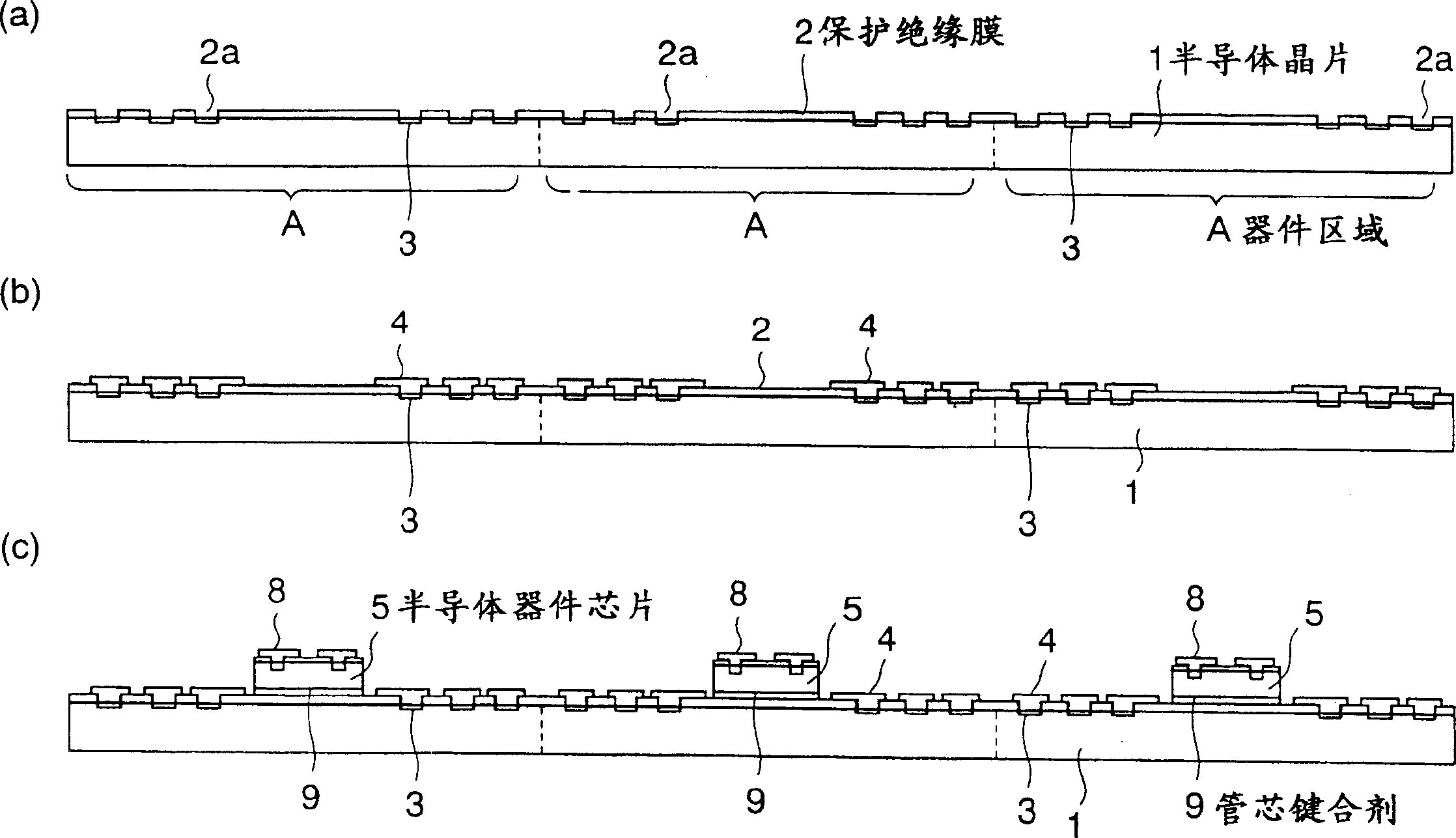

[0037] Figure 2 to Figure 5 It is a sectional view showing the formation process of the multi-chip package (MCP) in Embodiment 1 of this invention.

[0038] First, if figure 2 As shown in (a), a semiconductor wafer 1 in which first semiconductor circuits (not shown) are formed on a plurality of device regions A is prepared. Semiconductor wafer 1 such as Image 6 As shown in the partial enlarged view of (a), there is a protective insulating film 2 on the upper surface, and an opening 2a exposing the first terminal (conductive pad) 3 is formed on the protective insulating film 2, and the first terminal and the semiconductor Internal wiring (not shown) of the device is electrically connected. The first terminal 3 is formed of aluminum, copper, or the like.

[0039] Furthermore, the semiconductor wafer 1 is, for example, a silicon wafer, and is cut into individual first semiconductor circuits in a post-process, and is divided into units of device regions A. As shown in FIG. ...

Embodiment approach 2

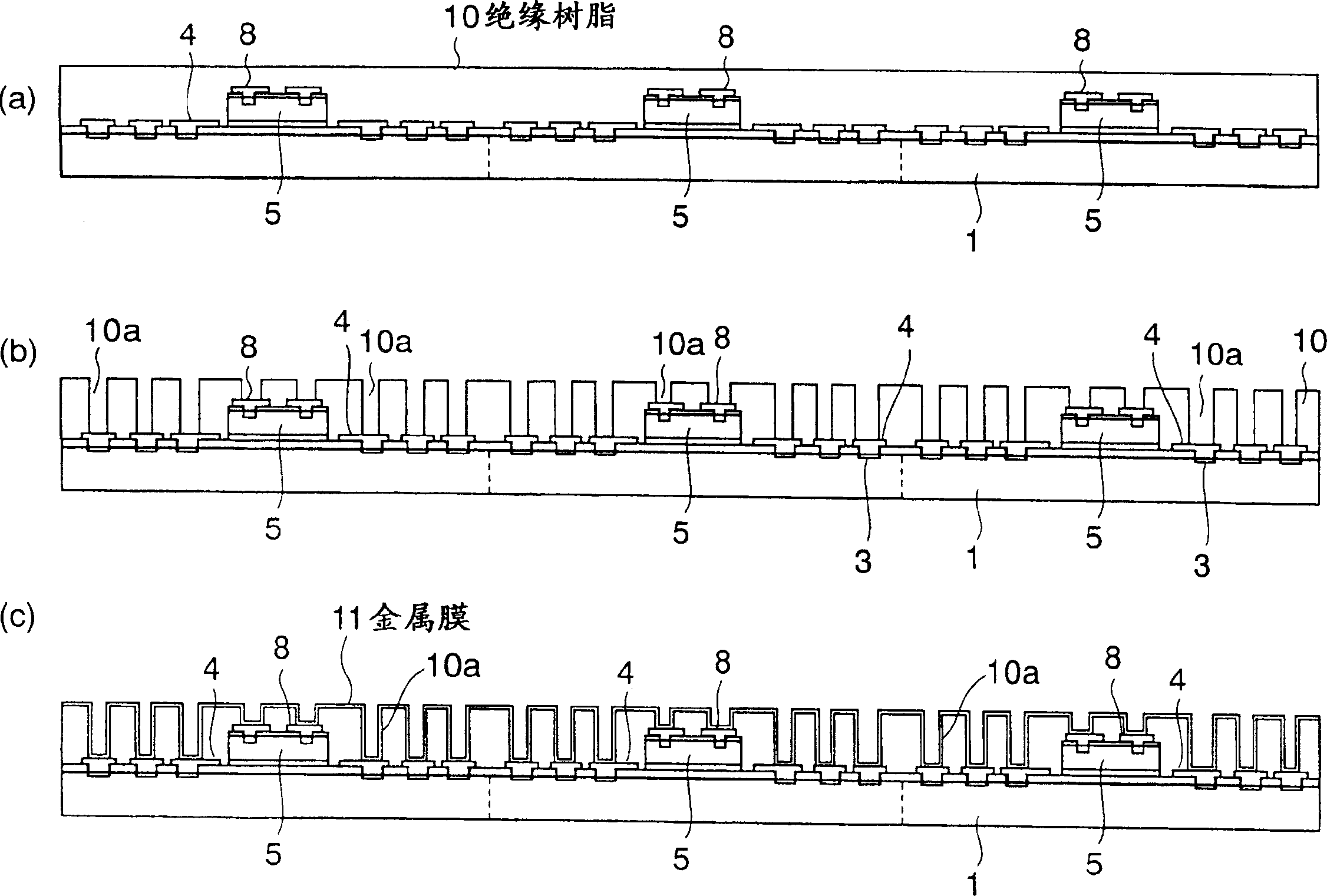

[0067] In Embodiment 1, after the via 11 a and the rewiring pattern 11 b are formed, the buried insulating layer 12 is formed in the via hole 10 a, and then the resin cover film 13 is formed on the resin insulating layer 10 . However, it is also possible to form the buried insulating layer 12 and the resin cover film 13 at the same time.

[0068] For example Figure 9 As shown in (a), after the photosensitive resin film 15, such as epoxy resin, is coated simultaneously in the via hole 10a and on the resin insulating layer 10, the exposure and development of the resin film 15 form the third rewiring pattern 11b. The opening 15a through which the terminal portion is exposed.

[0069] later as Figure 9 As shown in (b), the external terminal 14 is joined to the rewiring pattern 11b through the opening 15a of the resin film 15 .

[0070] According to this embodiment, the epoxy resin in the via hole 10a is used as the buried insulating layer, and the epoxy resin on the resin ins...

Embodiment approach 3

[0073] When the first rewiring pattern 3 is not formed on the semiconductor wafer 1 described in Embodiment 1, the following steps are employed.

[0074] First, if Figure 11 As shown in (a) and (b), on the terminal 3 in the opening 2a of the protective insulating film 2 on the semiconductor wafer 1, the electroless plating method is used to selectively form 3-5 μm thickness made of nickel phosphorus (NiP), nickel , gold, etc. to form a coating conductive layer 16.

[0075] later as Figure 11 As shown in (c), the first semiconductor device chip 5 is mounted on the semiconductor wafer 1 by the same method as in the first embodiment. As the first semiconductor device chip 5, a device having a structure in which a NiP-coated conductive film 17 is formed on the second terminal 7 of the protective insulating film 6 without forming a rewiring pattern is used.

[0076] Then as Figure 12 As shown in (a), a resin insulating layer 10 is formed on the semiconductor wafer 1 so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com