Nano-sized release, control medicinal fertilizer and its preparation method

A production method and nano-scale technology, applied in the form of fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of low utilization rate of effective nutrients, excessive soil harmful residues, and high prices of controlled-release products, so as to reduce environmental and environmental pollution. Effects of groundwater pollution, improved nutrient use efficiency, and improved adaptive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

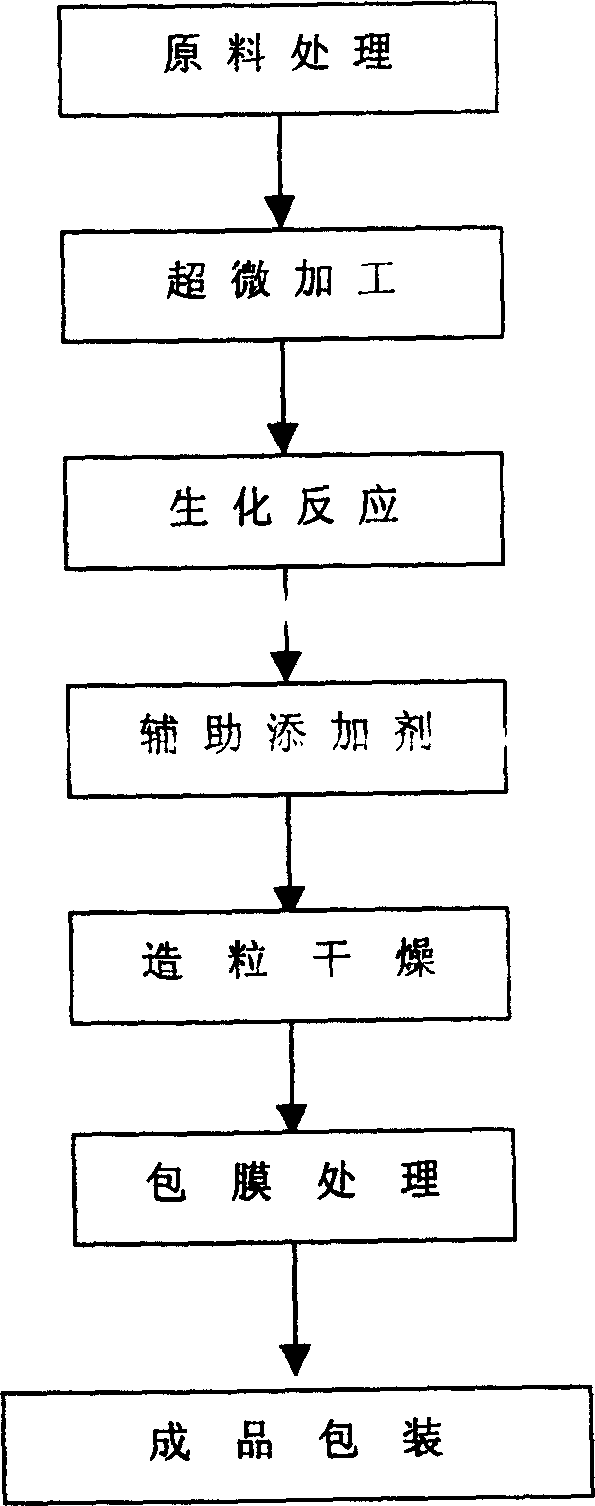

Image

Examples

Embodiment 1

[0021] Get ammonium humate (HA35%, nitrogen 5%) 300kg; Organic nitrogen (urea nitrogen 46%) 100kg; Superphosphate (P 2 o 5 20%) 200kg; calcium potassium pyrophosphate (40%) 100kg; potassium sulfate (40%) 100kg; glauconite mineral powder (40%) 300kg; Cu, Mn, Zn, B, Mo), 10kg; process water 200kg.

[0022] Humic acid raw material peat lignite (50%), glauconite ore powder (K 2 O content is 40%), ball milled to 190 mesh sieve respectively, through biological treatment and biochemical reaction; then add trace elements (Fe, Cu, Mn, Zn, B, Mo) and binders in proportion after ultramicroprocessing , active agent, amino acid, chitosan, picerillin, alkaloid, and membrane substance, after mixing, compounding, and granulating, they form finished products with various contents and uses. Among them, the granulation and coating equipment is a rotary disc granulator, with a diameter of 2.5m-3.0m, a height of 0.35m-0.50m, a thickness of 0.03m, and a speed of 15r / min-25r / min. Compounding, dr...

Embodiment 2

[0026] Get ammonium humate (HA35%, nitrogen 5%) 150kg; Superphosphate (P 2 o 5 15%) 150kg; calcium potassium pyrophosphate (40%) 100kg; potassium sulfate content (45%) 90kg; glauconite mineral powder (40%) 600kg; , Cu, Mn, Zn, B, Mo) 10kg; process water 400kg-480;

[0027] Manufacturing process is the same as embodiment 1.

Embodiment 3

[0029] Get glauconite ore powder (35%-52%), 800kg-1000kg; superphosphate (P 2 o 512%-20%), 500kg-800kg; ammonium humate (HA30%-40%, nitrogen 5%), 200kg-700kg; auxiliary additives (amino acids, chitosan, picrethrin, Fe, Cu, Mn, Zn, B, Mo), 6kg-12kg; process water 320kg-480kg;

[0030] Manufacturing process is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com