Novel thermal insulation and heat preservation building structure and construction technique

A technology for thermal insulation and building structure, applied in building components, building structure, thermal insulation, etc., can solve problems such as poor waterproof performance, low construction efficiency, and reduced thermal insulation effect, achieve good thermal insulation performance, improve The effect of construction efficiency and material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

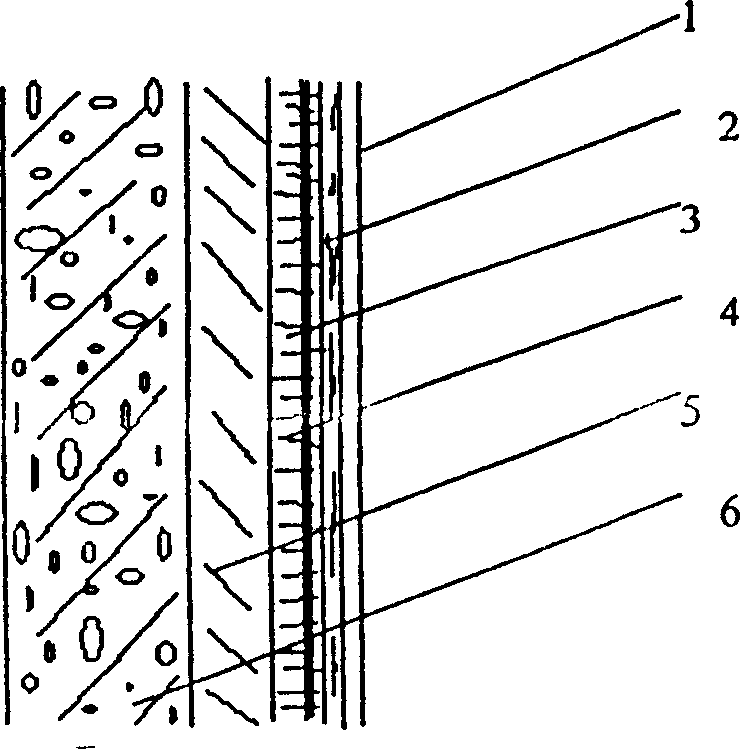

[0034] Embodiment 1: A new type of thermal insulation building structure, including a wall, a thermal insulation layer, an anti-crack layer, and a finish layer. The thermal insulation layer is a new type of multifunctional thermal insulation mortar. Its components and The content (weight) is: 1 part of polystyrene particle B, 8 parts of composite dry powder material A, and 6 parts of water; wherein the components and content (weight) of composite dry powder material A are: cement 61%, silica-alumina hollow glass sphere material 20% , fiber 1.47%, air-entraining agent 0.03%, modifier 5%, water reducing agent 1.5%, tackifier 1.9%; the anti-cracking layer is a kind of polymer modified anti-cracking mortar, and the surface layer is coated with penetrating elastic waterproof maintenance Liquid, waterproof curing liquid is a kind of acrylic organic elastic coating, which is coated with alkali-resistant glass fiber mesh cloth on the superficial layer of anti-cracking mortar, and then ...

Embodiment 2

[0035] Embodiment 2: A new type of thermal insulation building structure, including a wall, a thermal insulation layer, an anti-crack layer, and a finish layer. The thermal insulation layer is a new type of multifunctional thermal insulation mortar. Its components and The content (weight) is: 1 part of polystyrene particle B, 13 parts of composite dry powder material A, and 15 parts of water; wherein the components and content (weight) of composite dry powder material A are: cement 69%, silica-alumina hollow glass sphere material 23.15% , fiber 5%, air-entraining agent 0.05%, modifier 1%, water reducing agent 0.2%, tackifier 0.7%; the anti-cracking layer is a fiber-reinforced polymer modified anti-cracking mortar, and the surface layer is coated with infiltration type elastic Waterproof curing liquid, waterproof curing liquid is a kind of acrylic organic elastic coating, which is laminated with alkali-resistant glass fiber mesh cloth on the superficial layer of anti-cracking mo...

Embodiment 3

[0036]Embodiment 3: A new type of thermal insulation building structure, including a wall, a thermal insulation layer, an anti-crack layer, and a finish layer. The thermal insulation layer is a new type of multifunctional thermal insulation mortar. Its components and The content (weight) is: 1 part of polystyrene particle B, 9 parts of composite dry powder material A, and 10 parts of water; wherein the components and content (weight) of composite dry powder material A are: cement 65%, silica-alumina hollow glass sphere material 26.69% , fiber 3%, air-entraining agent 0.01%, modifier 3%, water reducer 0.9%, tackifier 1.4%; the anti-crack layer is a fiber-reinforced polymer modified anti-crack mortar, and the surface layer is coated with infiltration type elastic Waterproof curing liquid, waterproof curing liquid is a kind of acrylic organic elastic coating, the component and content (weight) of fiber-reinforced polymer modified anti-cracking mortar are: 1 part of anti-cracking r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com