Multiple array copper-manganese thin film super high pressure transducer and method for making same

A technology of ultra-high pressure and sensors, which is applied to the measurement of the properties and forces of piezoelectric resistance materials, etc., can solve the problems of high test costs, insulation performance degradation, sensor signal attenuation, etc., to eliminate high-voltage bypass effects and improve measurement accuracy The effect of improving and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

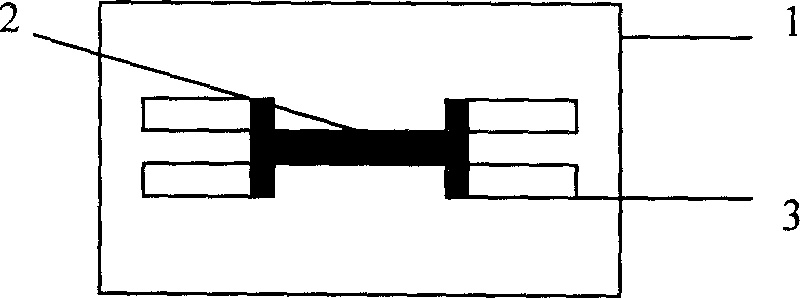

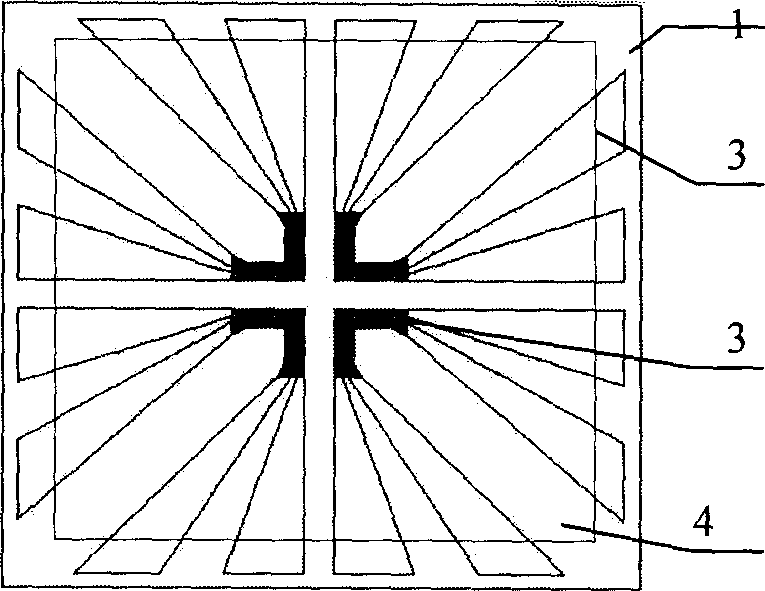

[0022] Arrayed manganese-copper thin-film ultra-high pressure sensor composed of four pressure-sensitive elements manganin-copper thin-film 2

[0023] Prepared using the following steps:

[0024] 1. At first on the silicon dioxide substrate 1, deposit the manganese-copper film and the copper electrode successively with the method of magnetron sputtering;

[0025] 2. Etching by photolithography according to the array structure: 4 manganese-copper thin films 2 of pressure sensitive elements and 4×4 copper electrodes 3,

[0026] Four pressure-sensitive element manganese-copper films 2 are symmetrically and evenly distributed, and each pressure-sensitive element manganese-copper film 2 is connected to four electrodes 3; each pressure-sensitive element manganese-copper film 2 has a size of 5×1 mm and a thickness of 1-5 μm; copper electrodes 3 leads are fan-shaped, such as figure 2 As shown, the thickness is 2-8 μm;

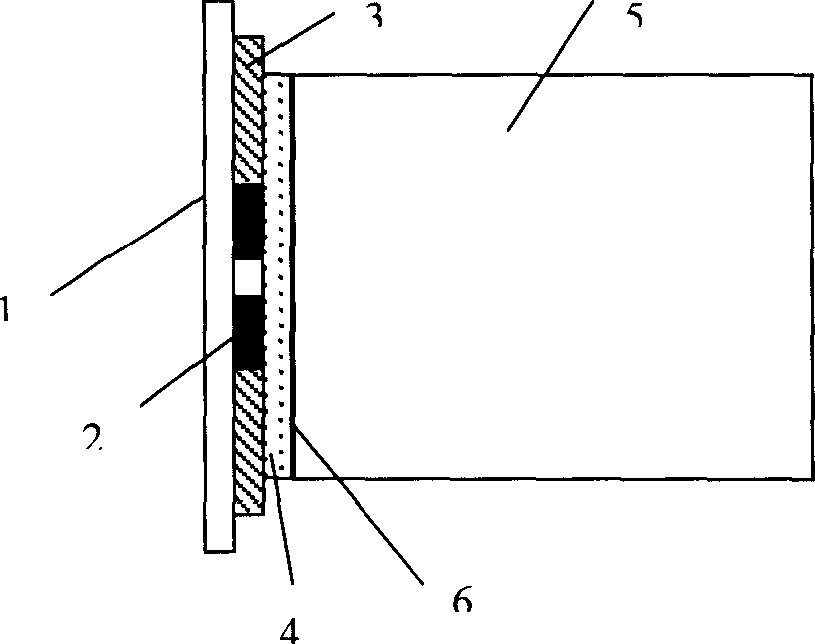

[0027] 3. Then use the electron beam evaporation method to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com