Process for synthsizing protecting layer of blast nozzle on furnace by in-situ burning

A technology of in-situ combustion and protective layer, applied in the direction of tuyere, etc., can solve the problems of general wear resistance and energy saving effect, complex preparation method and high cost, and achieve the effect of remarkable energy saving effect, simple preparation process and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

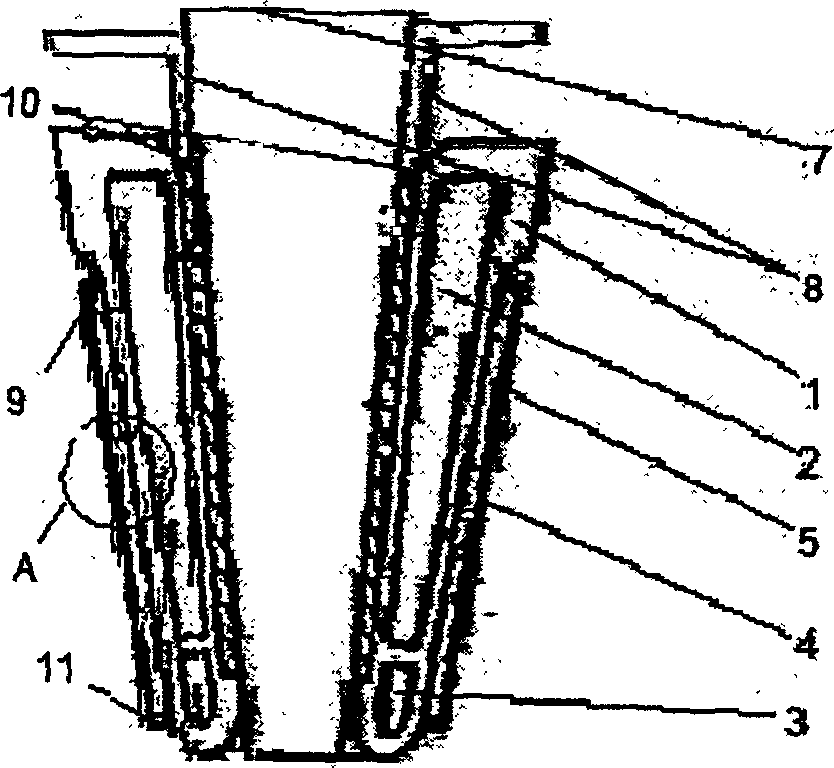

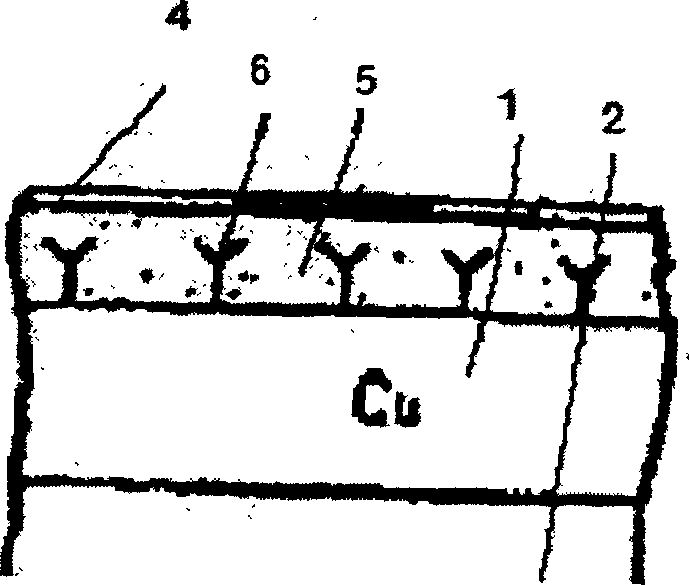

[0028] Example 1: 50% by weight of CrO 3 Powder (0.150mm~0.075mm) and 20% by weight of Al powder (0.150mm~0.075mm), 30% by weight of Al 2 o 3 powder (0.150mm-0.075mm), plus 1% by weight of aluminum dihydrogen phosphate solution and stirred evenly to obtain a material with certain plasticity. Under the pressure of 50MPa, the combustion synthetic material is composed of figure 1 Combustion synthetic material is squeezed into the tuyere cavity at 9 places of the extrusion port, and is extruded from 11 places of the combustion synthetic material extrusion port; The cavity formed by the core and the inner surface of the tuyere. The blank was dried at 300°C for 2 hours. In the atmospheric environment at normal temperature, the tungsten wire is energized to ignite and burn the material at the extrusion inlet 9 of the synthetic material, so that the billet can achieve self-propagating sintering. The density of the sintered product is 1.4g / cm 3 , the porosity is 57%, the thermal ...

example 2

[0029] Example 2: with (0.150mm~0.075mm) 40% by weight of CrO Powder and 15% by weight of Cr of the same particle size 2 (SO4)3 powder, 18.5% by weight (0.150mm~0.075mm) Al powder, 26.5% by weight (0.150mm~0.075mm) Al 2 o 3 The powder is added with 2% by weight of aluminum sulfate solution and stirred evenly to obtain a material with certain plasticity. Such as figure 1, Under the pressure of 10MPa, the burning synthetic material squeezes in and ignites the same way as Example 1. The porosity of the sintered product is 30%, the normal temperature compressive strength is 22MPa, and the refractoriness is greater than 1750°C.

example 3

[0030] Example 3: 75.3% by weight of chromite less than 0.3mm, 20.5% by weight of Al powder (0.150mm~0.075mm) less than 0.3mm, and 4.2% by weight of aluminum sulfate solution are stirred evenly to obtain a material with certain plasticity . Such as figure 1 , Under the pressure of 50MPa, the injection method and ignition method of the combustion synthetic material are the same as in Example 1. The porosity of the sintered product is 57%, the normal temperature compressive strength is 58.8MPa, and the refractoriness is greater than 1790°C.

[0031] Example 4: 78.5% by weight of magnesium chromate (0.150mm ~ 0.035mm), 16.4% by weight of Al-Mg powder (0.150mm ~ 0.075mm), 0.1% by weight of Al 2 o 3 powder (0.350mm-0.035mm), adding sodium dihydrogen phosphate solution containing 35% by weight of ethanol and water as a solvent and uniformly mixing to obtain a blank with certain plasticity. Such as figure 1 , Under the pressure of 10MPa, the burning synthetic material squeezes i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com