Method for mfg. magnetic drum of high resolution magnetic-encoded device

A high-resolution, magnetic encoder technology, applied in the field of preparation of high-resolution magnetic encoder drums, can solve the problems of low precision and high yield of magnetic ring magnetic drums, and achieve easy mass production and high yield , good signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

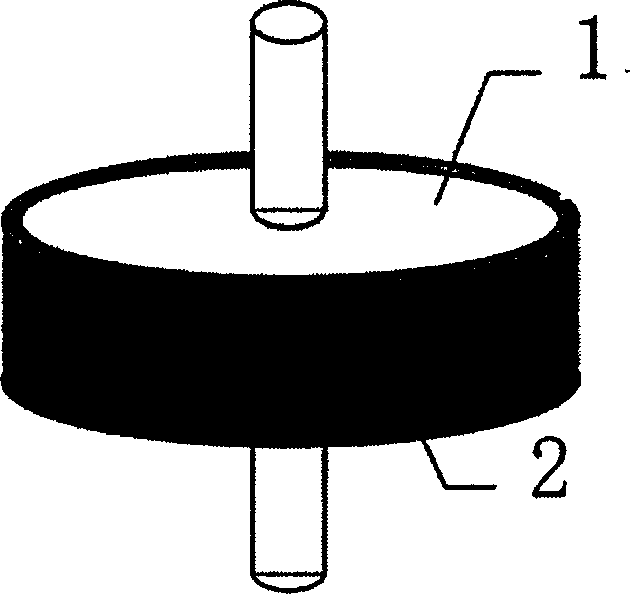

[0019] 1. Al drum cleaning

[0020] The diameter of the Al drum is selected as 30 mm, and the aluminum drum is ultrasonically cleaned with acetone, deionized water, and absolute ethanol in sequence to remove oil stains and physical adsorption on the surface.

[0021] 2. Magnetic slurry preparation and coating

[0022] γ-Fe with 690 Oe 2 o 3 Magnetic powder 7g, binder epoxy resin 10g, diluent acetone 7.5g, curing agent T-31 2.5g, dispersant silane 1g. After high-speed stirring and sand grinding, a uniform magnetic slurry is made, coated on the aluminum drum base, and solidified by rotation. When the magnetic slurry is in a semi-solidified state, it is extruded with a high-flatness bearing to make the coating thickness 0.15mm.

[0023] 3. Magnetization test

[0024] After the magnetic layer is completely cured, the 1024PPR high-resolution optical encoder and the magnetic drum to be magnetized are installed on the same shaft and driven by a low-speed motor to rotate at a con...

Embodiment 2

[0026] 1. Al drum cleaning

[0027] Al drum diameter is selected 36mm for use. Cleaning procedure is identical with embodiment 1.

[0028] 2. Magnetic slurry preparation and coating

[0029] γ-Fe with 690 Oe 2 o 3 Magnetic powder 10g, binder epoxy resin 10g, diluent acetone 8g, curing agent T-31 2.5g, dispersant silane 1.5g. The preparation process is the same as in Example 1. The resulting coating has a thickness of 0.20 mm.

[0030] 3. Magnetization test

[0031] Same as embodiment 1, write 256 pairs of poles to the magnetic drum at last.

Embodiment 3

[0033] 1. Al drum cleaning

[0034] Al drum diameter selects 40mm for use. Cleaning procedure is identical with embodiment 1.

[0035] 2. Magnetic slurry preparation and coating

[0036] γ-Fe with 690 Oe 2 o 3 Magnetic powder 12g, binder epoxy resin 10g, diluent acetone 9g, curing agent T-312.5g, dispersant silane 2.5g. The preparation process is the same as in Example 1. The resulting coating has a thickness of 0.30 mm.

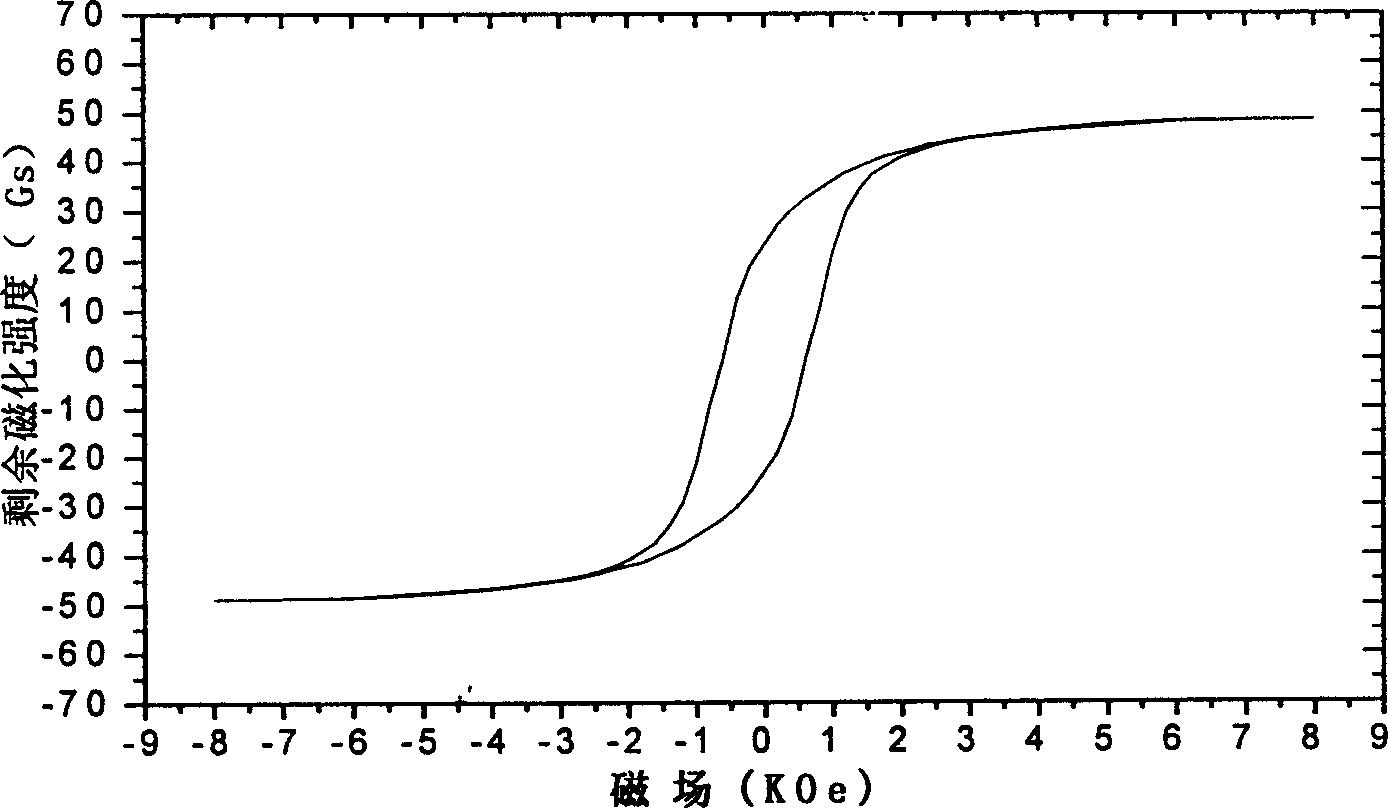

[0037] The hysteresis loop of the fabricated magnetic layer is as figure 2 shown.

[0038] 3. Magnetization test

[0039] Same as embodiment 1, write 256 pairs of poles to the magnetic drum at last.

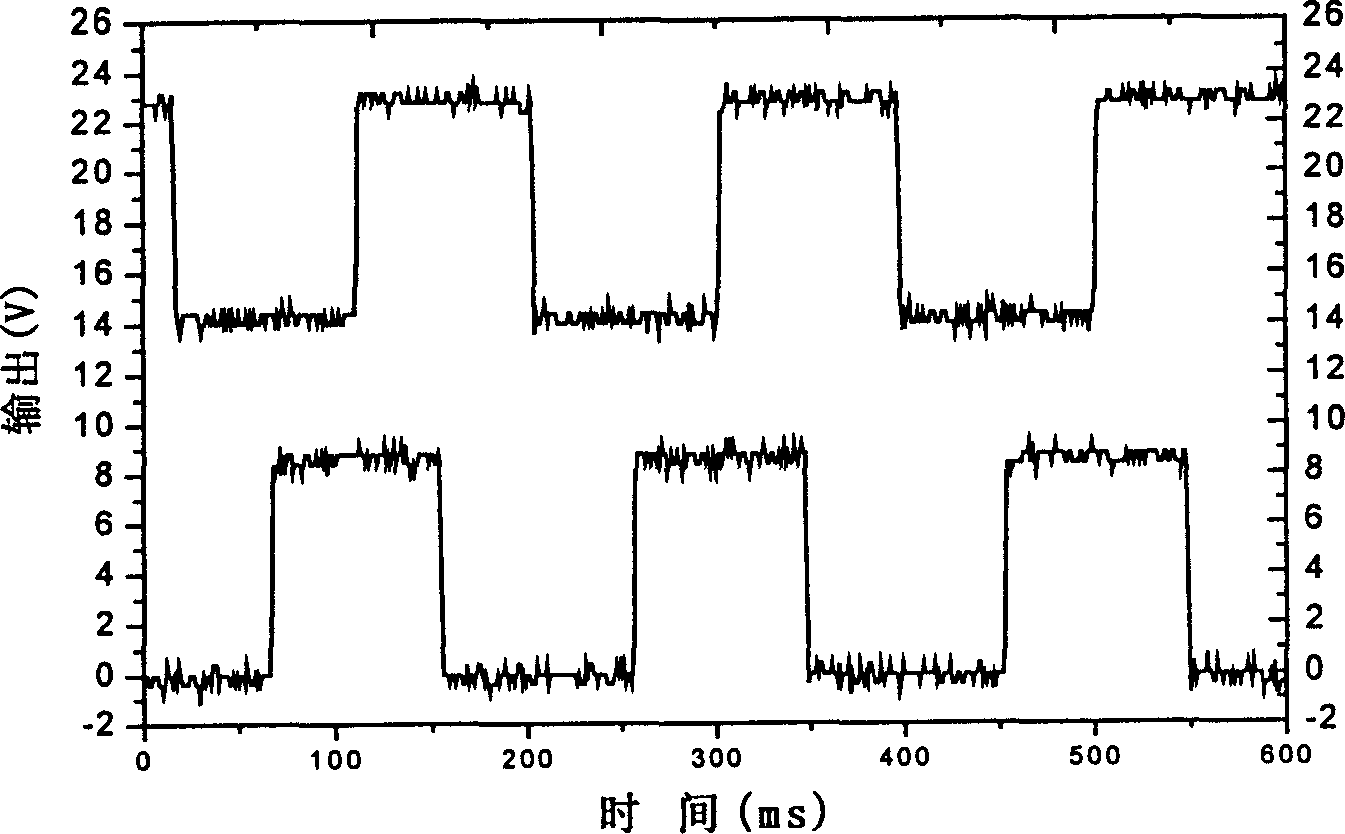

[0040] The oscilloscope waveform output after the drum writes 256 pairs of poles is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com