Structure of flow field board for proton exchange film fuel cell

A proton exchange membrane and fuel cell technology, applied in fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems of voltage instability, reaction dead zone, easy accumulation of water, etc., to increase the effective use area, speed up The effect of reaction rate and utilization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The natural high-purity graphite powder, polymer materials, additives, etc. are mixed in a certain proportion and then put into the mold, and the mold is put into the plate vulcanizing machine. Under 10~100MPa and 100~300℃, one-time compression molding becomes a composite double containing flow field. Plate products.

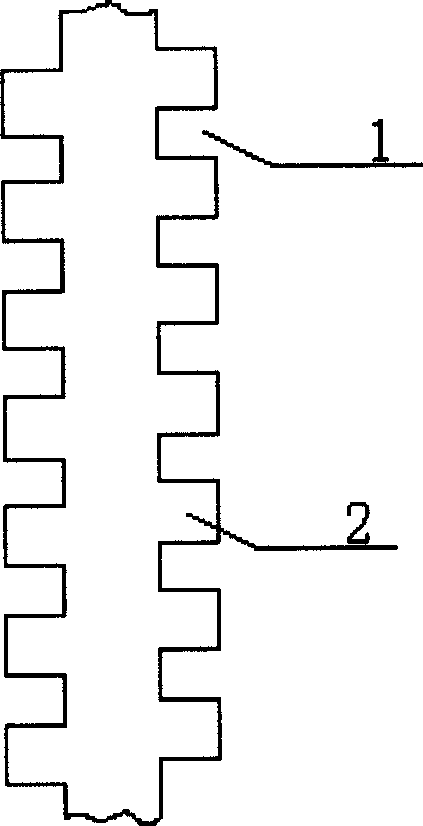

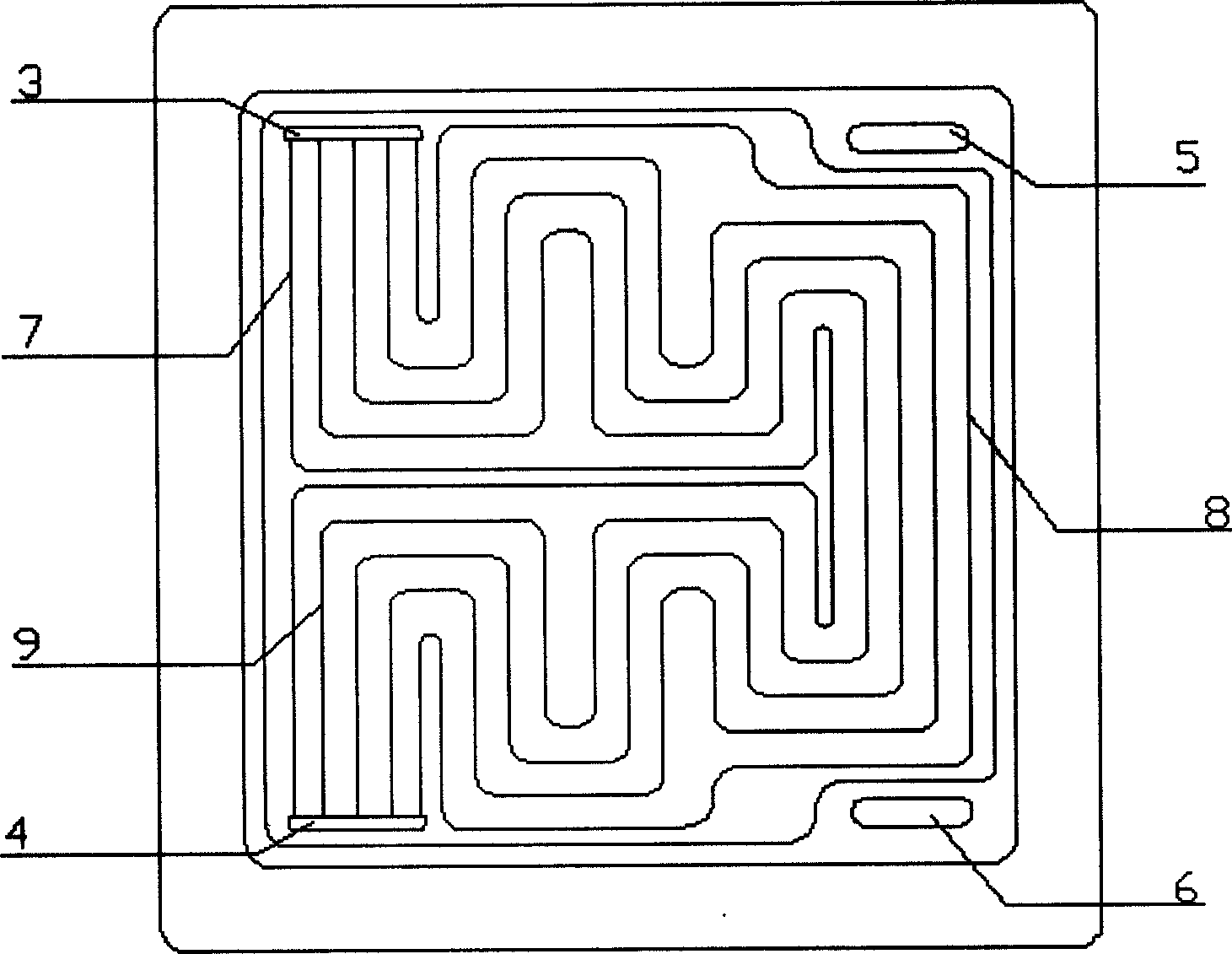

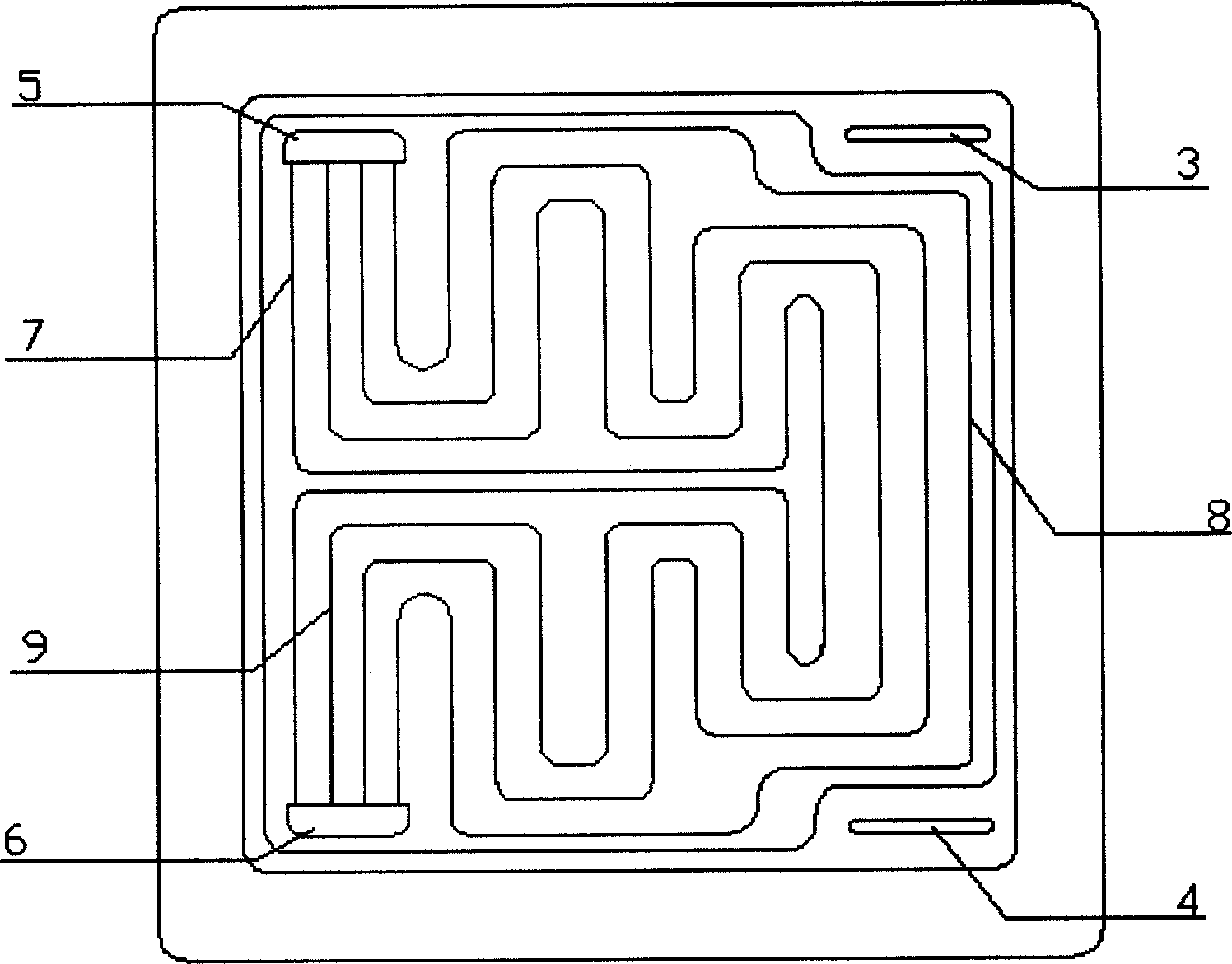

[0033] A flow field plate structure for a proton exchange membrane fuel cell includes a flow field plate body. The main body of the flow field plate is a flow guide bipolar plate, one side of which is a hydrogen flow field plate, and the other side is a flow field plate that guides air; Figure II It is the said hydrogen-conducting flow field plate. It is provided with a pair of diversion ports 3 and 4 for entering and exiting hydrogen, and they are distributed on the same side of the flow field plate. The hydrogen gas inlet and the hydrogen gas outlet are equal in size and shape. They are elongated rectangles with a width of 3mm and a length of 33mm. There a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com