Light polarizing device, a method of continuously fabricating same, and reflective optical devices using same

一种偏振光学、元件的技术,应用在光学元件、偏振元件、光学等方向,能够解决不能获得格栅型的偏振光学元件、金属脱落、不能实现大面积化作业等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

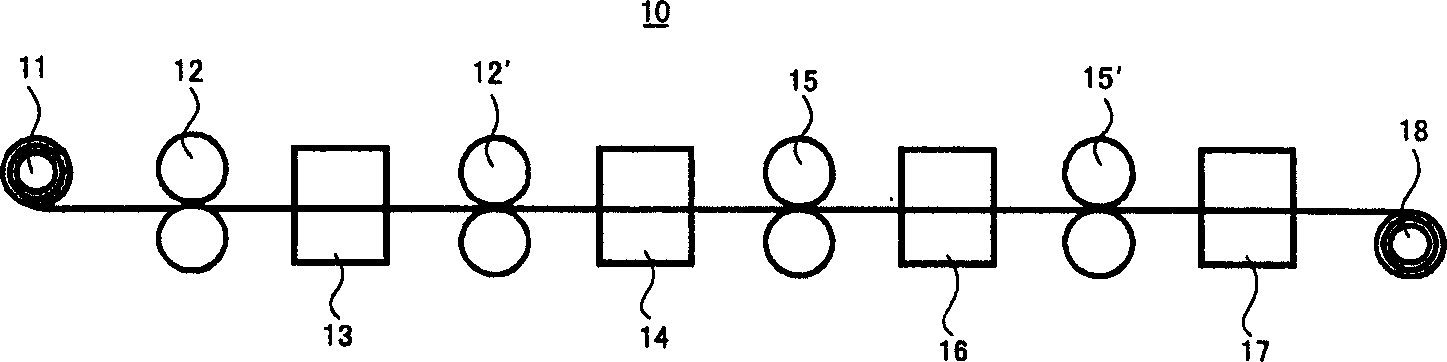

[0129] In Example 1, figure 1 It shows a continuous manufacturing device 10 that uses a polarizing optical element, and the aluminum metal is deposited on the surface of a polypropylene film by vapor deposition to manufacture a film-shaped polarizing optical element. First, the polypropylene film supplied from the polypropylene film supply roller 11 is stretched 4 times in the axial direction through the roller 12, the first thermostat 13, and the roller 12'. The rollers 12 and 12' are stretching means in the axial direction that utilize a difference in linear velocity. In addition, the first constant temperature bath 13 is installed in order to satisfy the stretching conditions, and it maintains a temperature of 100°C. In this post-vacuum vapor deposition tank 14, aluminum metal is vapor-deposited to have a thickness of 100 nm. Secondly, it passes through a roller 15, a second constant temperature bath 16 maintained at 120°C, and a roller 15' to further stretch twice in the axia...

Embodiment 2

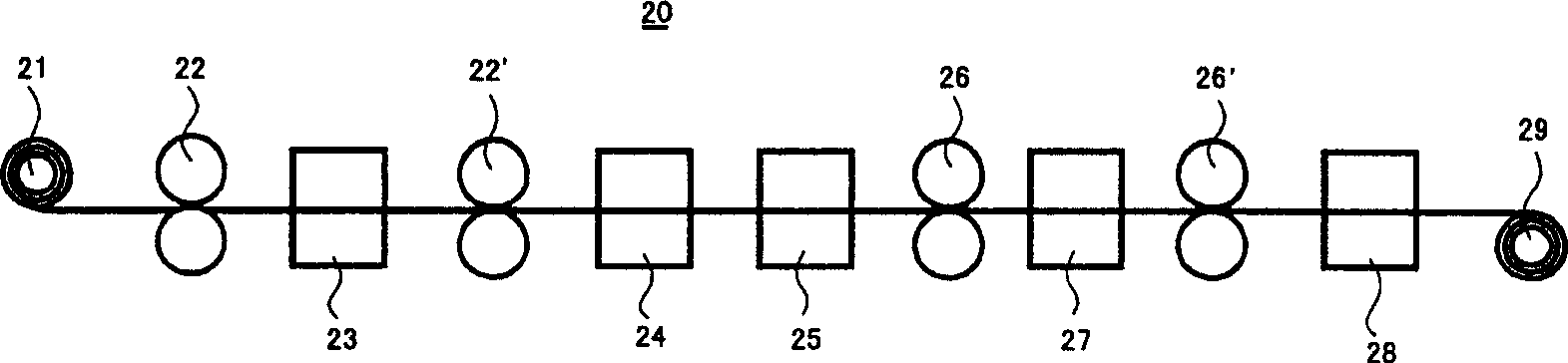

[0132] In Example 2, figure 2 It shows a continuous manufacturing device 20 that uses a polarizing optical element, and deposits aluminum metal on the surface of a polyvinylidene fluoride film by vapor deposition to manufacture a film-like polarizing optical element. First, the polyvinylidene fluoride film supplied from the polyvinylidene fluoride film supply roll 21 is passed through the roll 22, the first constant temperature bath 23 maintained at 60°C, and the roll 22' is stretched 5 times in the axial direction. After that, the tension is continued to be maintained, and a heat treatment is performed for 5 minutes in the second constant temperature bath 24 maintained at 120° C. to crystallize a part of the polyvinylidene fluoride film.

[0133]After that, the aluminum metal was vapor-deposited in a vacuum vapor deposition tank 25 with a thickness of 50 nm, and then passed through a roller 26, a third constant temperature bath 27 maintained at 80°C, and a roller 26' to further ...

Embodiment 3

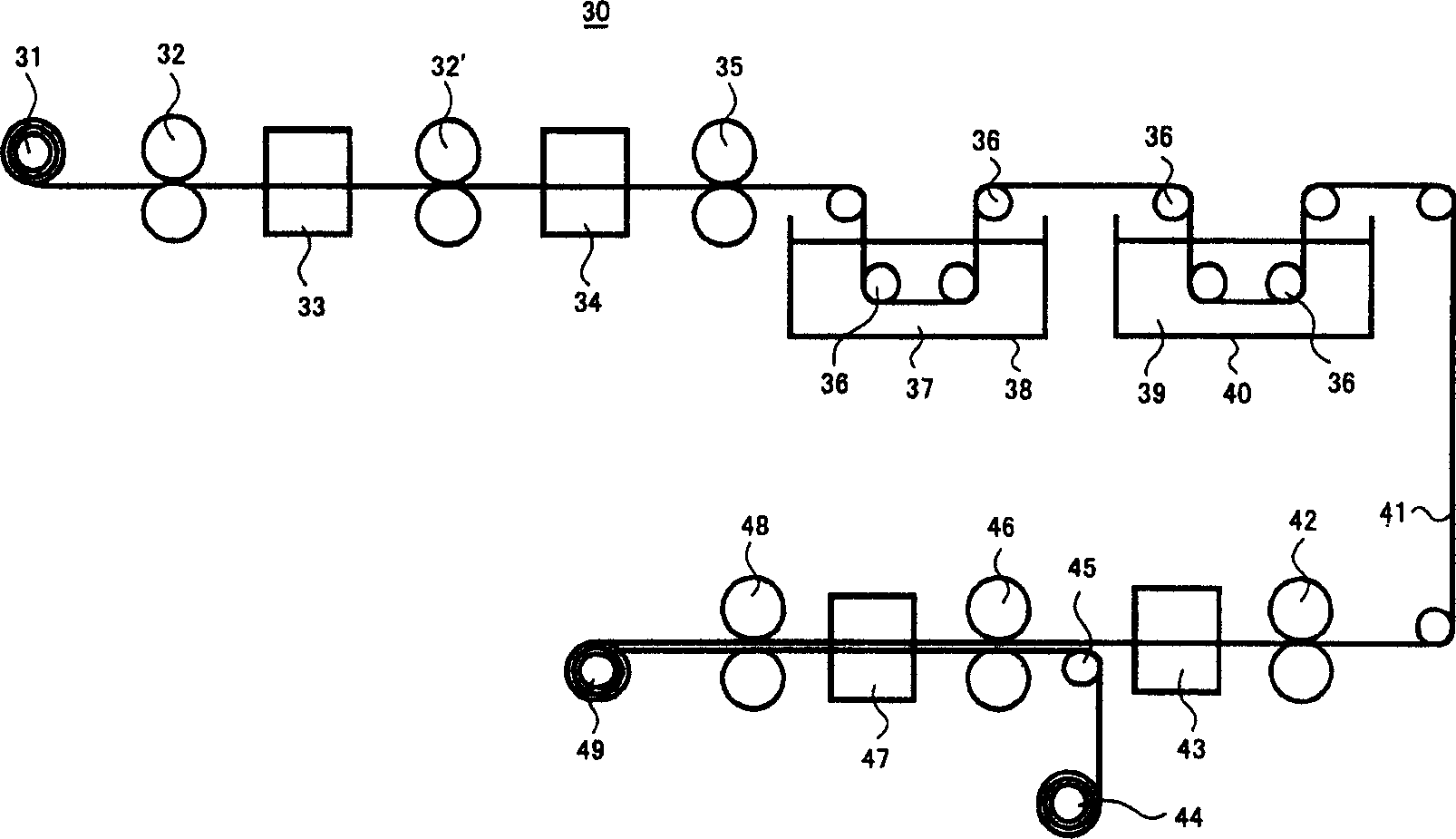

[0135] In Example 3, silver metal was deposited on the surface of the polypropylene film by electroless plating (electroless plating) to form a polarizing film. First of all. After the polypropylene film was stretched 5 times at 80°C, the tension was continued to be maintained, and a heat treatment was performed at 110°C for 10 minutes to crystallize a part of the polypropylene film. After the film is chlorinated through the first tin solution, it is gently rinsed with water. The amorphous part where the first tin chloride passed through the ammoniated silver nitrate solution is selectively adsorbed is only electrolessly plated to meet the uneven precipitation on the film surface Silver metal. The polarization performance of the obtained polarizing film showed a value of extinction ratio of 1:5000 in the visible light region of 420 nm to 700 nm. The light transmittance is 48%.

[0136] In addition, this Example 3 shows an example of using silver as the electroless plating layer. H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com