Niclosamide ethanolamine salt powder and its preparation method

A technology of niclosamide ethanolamine salt and ethanolamine salt powder, which is applied in the field of pesticide manufacturing, can solve problems such as constraints and lack of water for molluscicide, and achieve labor saving, significant social and economic benefits, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

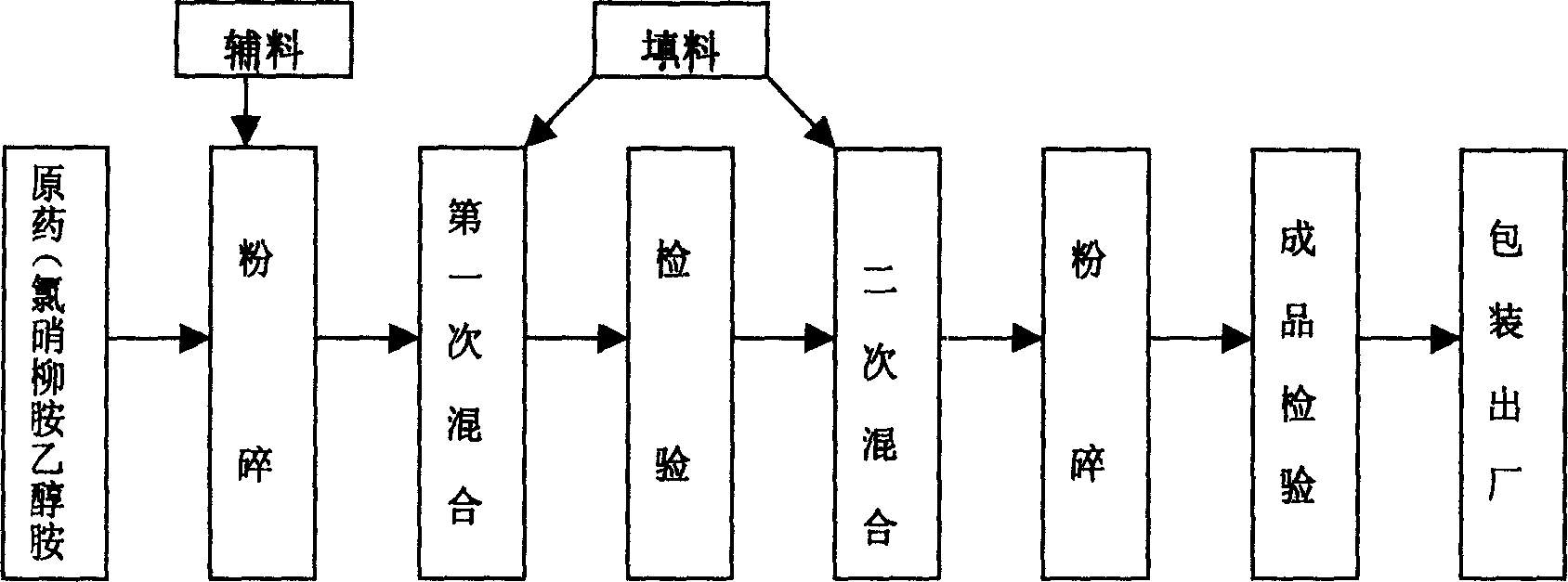

Method used

Image

Examples

Embodiment 1

[0026] In the embodiment of the present invention, 3.6% by weight of niclosamide ethanolamine salt, 1.2% by weight of sodium lignosulfonate, and 0.3% by weight of sodium dodecylbenzenesulfonate are added to the universal pulverizer for mixing and pulverization, and the loading rate of the mixer is 35-40%; the rotary speed of the mixer is 10-15r / min, and the mixing and crushing time is 20-25min / time; the powder semi-finished product and filler after the above crushing are selected from 180 mesh / inch kaolin: 94.9% by weight, and its total content Add the middle part into the horizontal ribbon mixer and mix evenly, the mixing ratio is 1:4, make 20% intermediate concentration powder, and check; then mix the intermediate concentration powder with remaining 180 mesh / inch kaolin (water content < 1%) is mixed evenly for the second time by 1: 4 to make 4% niclosamide ethanolamine salt powder, and then pulverized for the second time, the loading rate of the mixer is 35-40%; the speed of ...

Embodiment 2

[0037]In the embodiment of the present invention, take 4% by weight of niclosamide ethanolamine salt, 1.1% by weight of sodium lignosulfonate, and 0.2.5% by weight of sodium dodecylbenzenesulfonate and add them into a Raymond mill for mixing and pulverization. The loading rate is 35-40%; the rotation speed of the mixer is 10-15r / min, and the mixing and crushing time is 20-25min / time; the above-mentioned pulverized powder semi-finished products and fillers are selected from 180 mesh clay (water content <1%) : 94.65% by weight, part of its total content is added into a horizontal ribbon mixer and mixed uniformly, its mixing ratio is 1:4, and 20% intermediate concentration powder is made, and tested; then the intermediate concentration powder and multiplied The remaining 180 mesh potter's clay is mixed evenly for the second time at 1:4 to make 4% niclosamide ethanolamine salt powder, and then pulverized for the second time. The loading rate of the mixer is 35-40%; the rotation spe...

Embodiment 3

[0039] In the embodiment of the present invention, 4.4% by weight of niclosamide ethanolamine salt, 1.0% by weight of sodium lignosulfonate, 0.2% by weight of sodium dodecylbenzenesulfonate, and 180 mesh pottery clay (water content<1%) are used as filling materials. : 94.4% by weight. The proportioning of the above-mentioned components adopts the production process in the first and second examples, and the above-mentioned oncomelania killing effect can also be obtained after two times of crushing and two times of mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com