Electrical several-layer element and manufacturing method thereof

An electrical and protective layer technology, applied in the field of multi-layer electrical components, can solve the problems that affect the performance of PTC ceramics, silver and palladium are expensive, easy to penetrate into ceramics, etc., and achieve the effects of large mechanical offset, lower basic resistance, and high capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

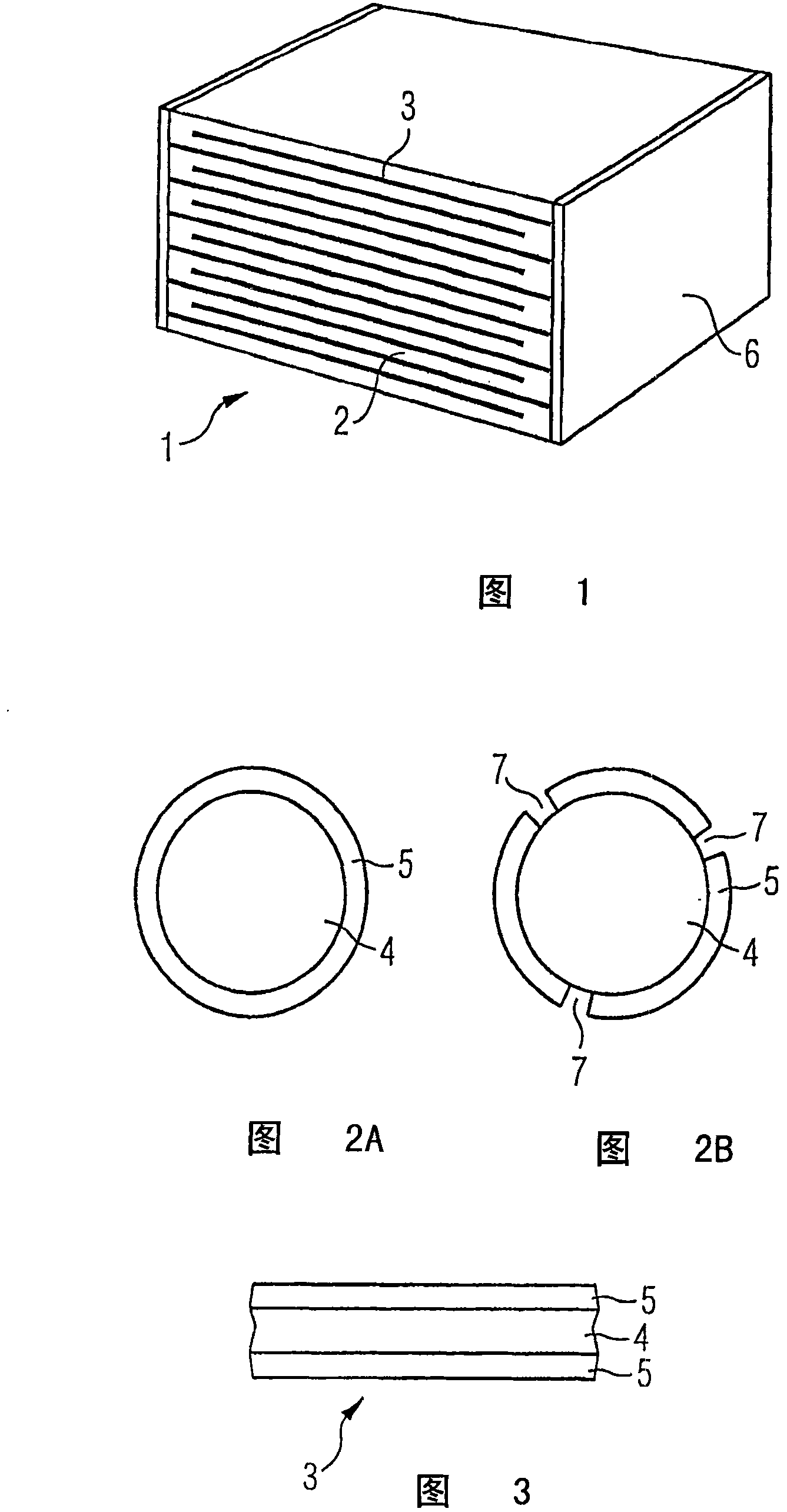

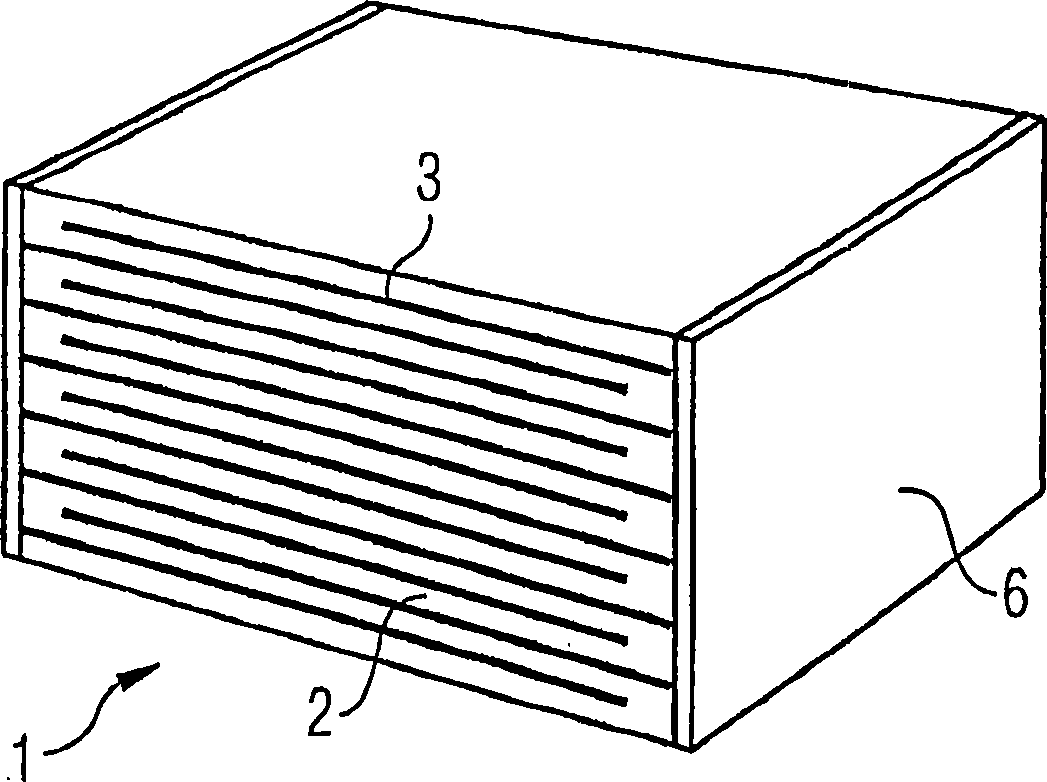

[0048] Figure 1 shows a component in a perspective view. It is made by sintering a stack of overlapping green and electrode layers. For this purpose, an electrode paste is applied to the areas of a green film surface intended for electrodes. Suitable methods for this are a series of, in particular thick-coating methods and preferably printing, for example by means of screen printing. At least at the edges of the green film or only at the corners of the green film, there remains a surface area which is not covered by the electrode paste. It is also possible to coat the electrodes not in planar layers but to structure them, if necessary in an intermittent pattern.

[0049] The screen printing paste has, for example, metal particles comprising metallic tungsten or tungsten compounds for producing the desired electrical conductivity and optionally also ceramic particles which can be sintered and for adapting the fading properties of the electrode paste to the fading properties o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com