Sodium dibromoisocyanurate as disinfectant and its production process

A technology of sodium dibromoisocyanurate and trichloroisocyanuric acid, applied in botany equipment and methods, biocides, animal repellents, etc., can solve the problems of pollution, inconvenience, etc., and achieve low price and convenient use , long-lasting disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

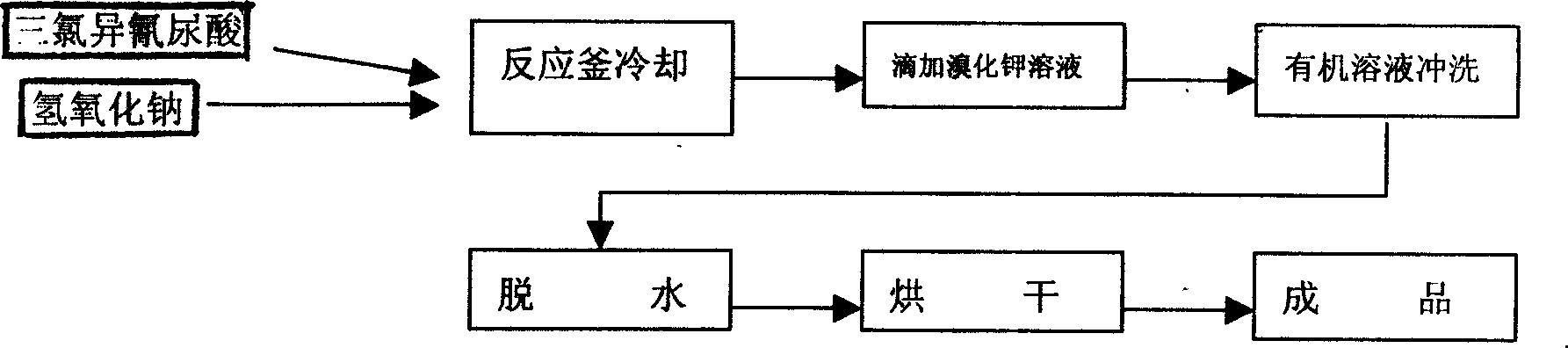

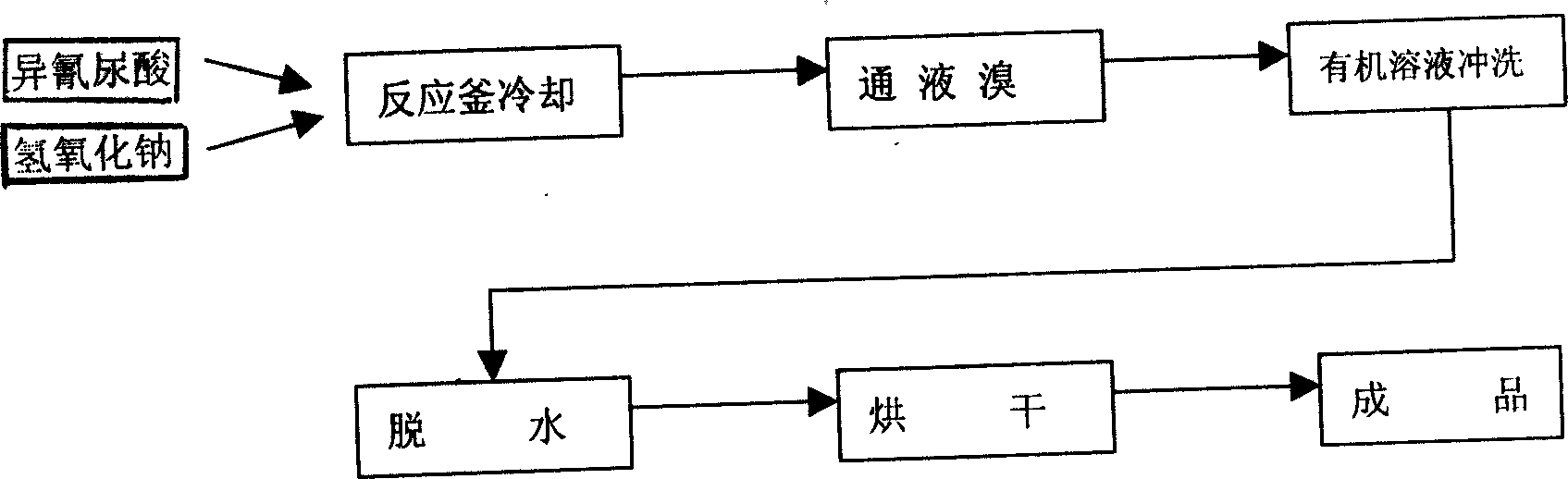

[0007] Provided by the prescription, sodium dibromoisocyanurate disinfectant (tablet) of the present invention is by weight percentage: sodium dibromoisocyanurate 23-70%, acidic substance 5-15%, disintegrant 5- 15%, sodium sulfate 5-15% and alkaline substance 5-15%, the total amount is 100%; said acidic substance is citric acid or tartaric acid or boric acid; said disintegrating agent is carboxymethyl cellulose Sodium or made of small soda (sodium bicarbonate) and citric acid in the ratio of 2:1 by weight; said alkaline substance is small soda (sodium bicarbonate), sodium carbonate; said dibromoiso Sodium cyanurate is made from 1 part (20%) of trichloroisocyanuric acid, 2 parts (40%) of sodium hydroxide and 2 parts (40%) of potassium bromide or liquid bromine by weight.

[0008] Realize that the production method of above-mentioned sodium dibromoisocyanurate disinfectant (sheet) is, at first prepare sodium dibromoisocyanurate, by figure 1 , figure 2 Given, by weight, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com