Laser annealing apparatus and annealing method

A laser annealing and laser technology, used in laser welding equipment, chemical instruments and methods, self-area melting methods, etc., can solve the problems of large energy loss, narrow energy condition range, silicon film damage, etc., to achieve excellent performance, mobility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the drawings of the embodiments.

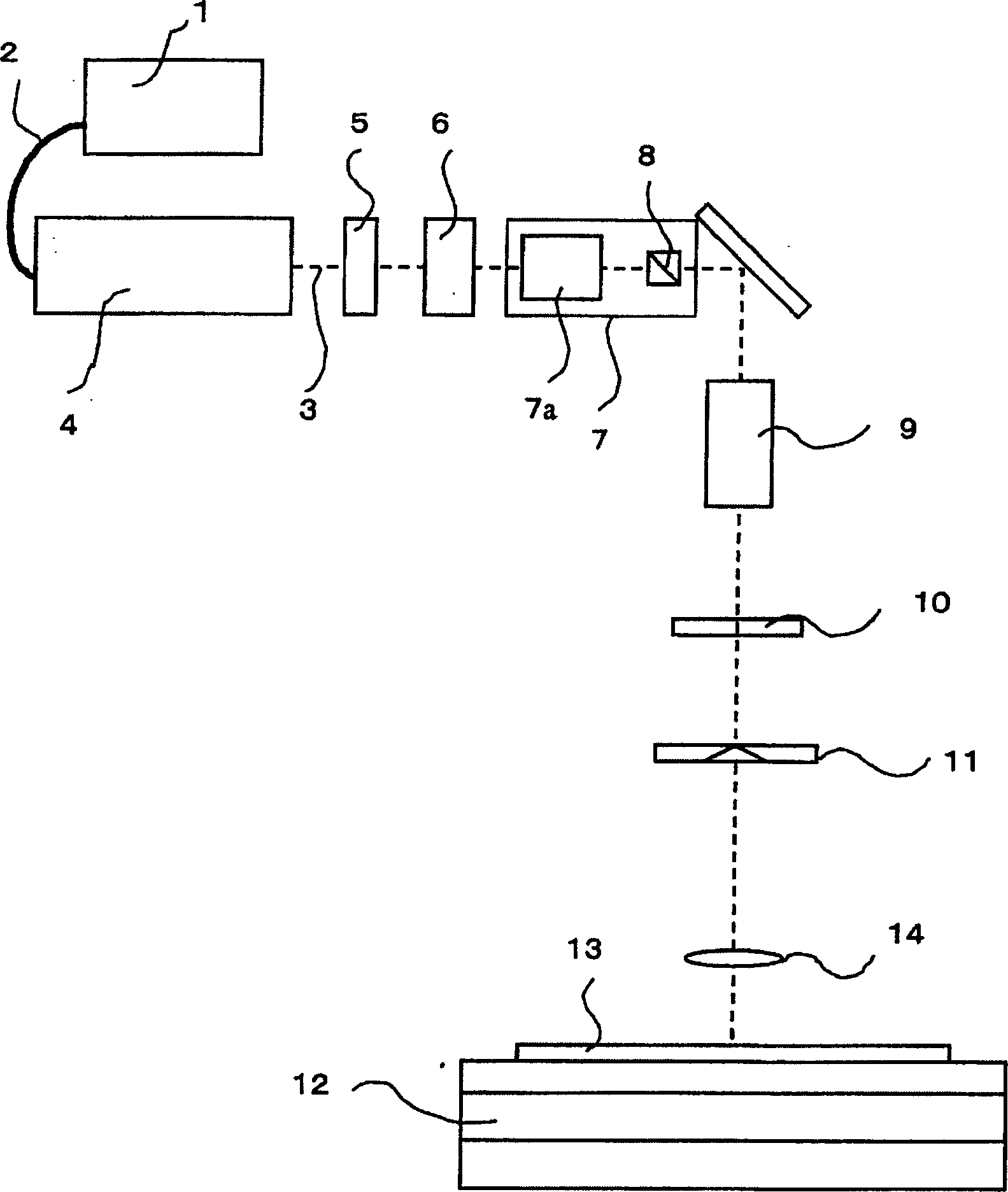

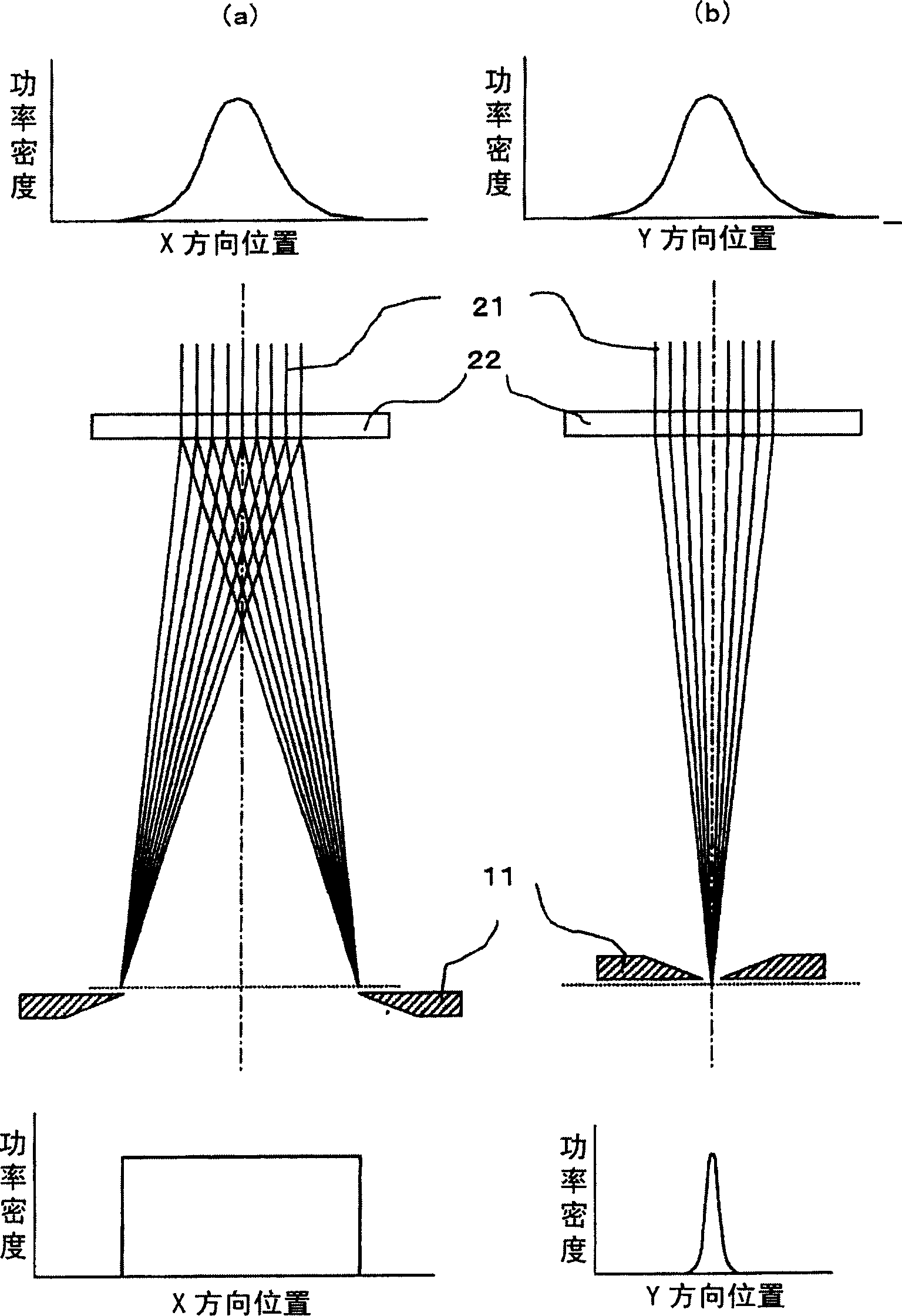

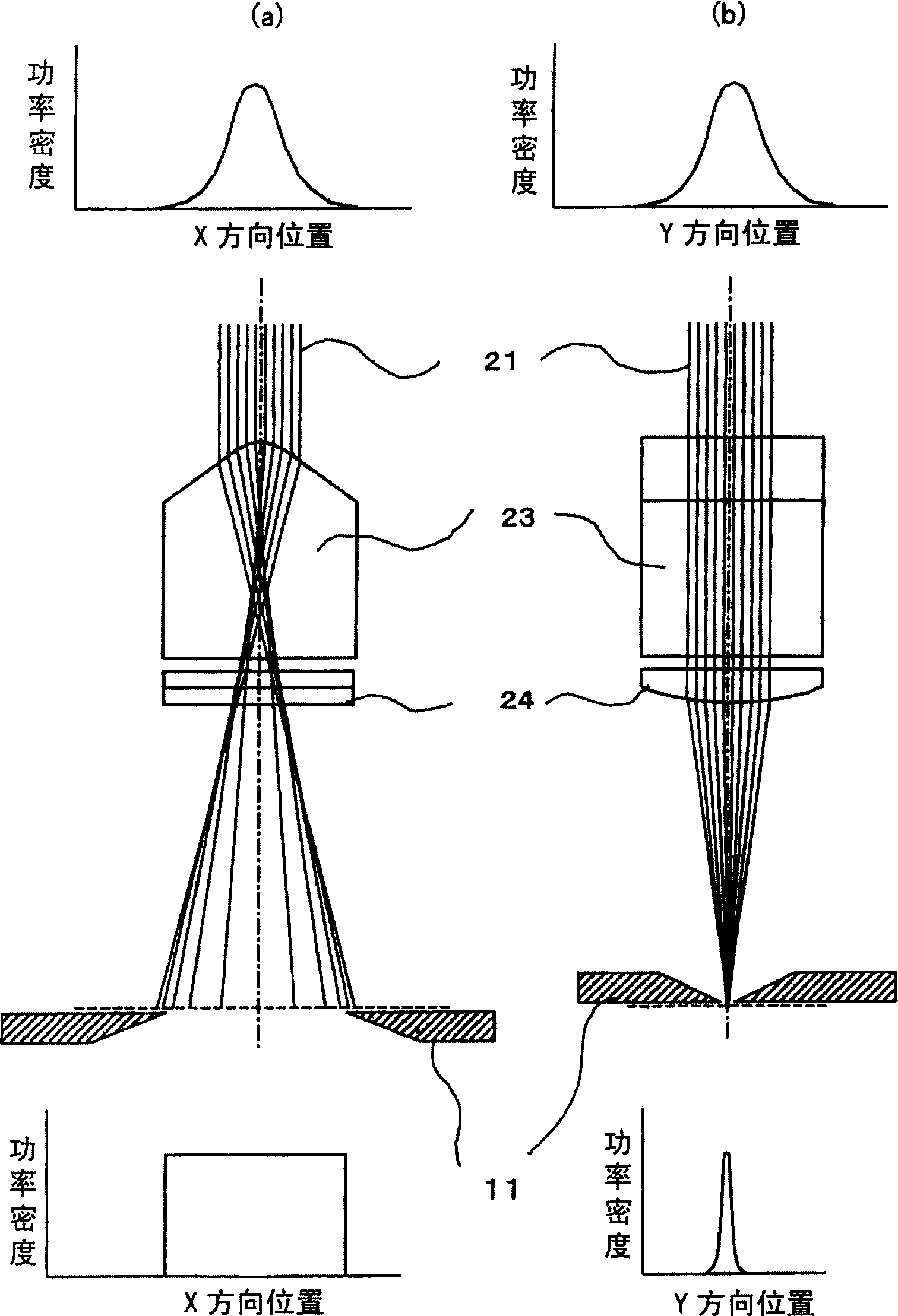

[0026] figure 1 is an optical structure diagram of a laser annealing device according to an embodiment of the present invention. The optical structure is composed of the following components: a laser oscillator 4 that is connected to an excitation LD (laser diode) 1 and an optical fiber 2 to generate a continuous oscillating laser 3, a shutter 5 for turning on / off the laser 3, and a shutter for adjusting the laser 3. An ND filter 6 with continuously variable energy transmittance, a modulator 7 for time-modulating the laser 3 output from the laser oscillator 4 to realize pulsed and time-modulated energy, and a beam for adjusting the laser 3 The beam expander (beam reducer) 9 of the diameter, the beam shaper 10 that the laser 3 is shaped into a slender shape such as a line, a rectangle, an ellipse, and an oblong beam, is used to shape the beam of the laser 3 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com