Heat insulation material for agriculture and horticultural facility

A thermal insulation material, agricultural and horticultural technology, applied in horticulture, agriculture, application, etc., can solve problems such as low weather resistance, decreased light transmittance, and poor thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] LaB 6 Microparticles (specific surface area 30m 2 / g) 20 parts by weight, 75 parts by weight of toluene, and 5 parts by weight of a dispersant were mixed, and after dispersion treatment, a dispersion liquid A having an average dispersed particle diameter of 80 nm was obtained. The solvent component was removed from this dispersion liquid A using a vacuum dryer at 50°C, and the dispersion-treated LaB 6 Powder A. In addition, the average dispersed particle diameter was measured with the dynamic light scattering method measuring apparatus (Otsuka Electronics Co., Ltd. (manufactured) ELS-800), and the average value was taken.

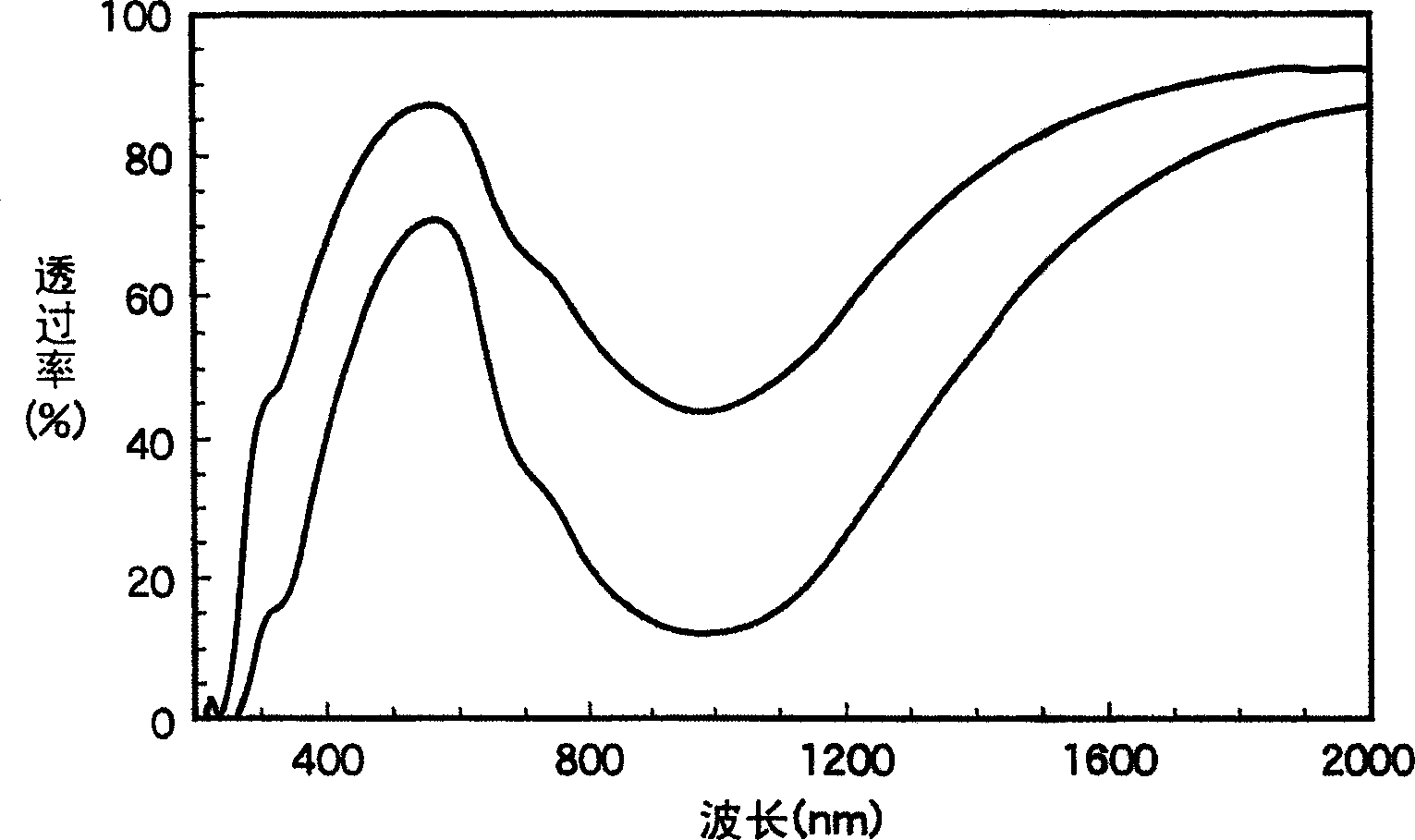

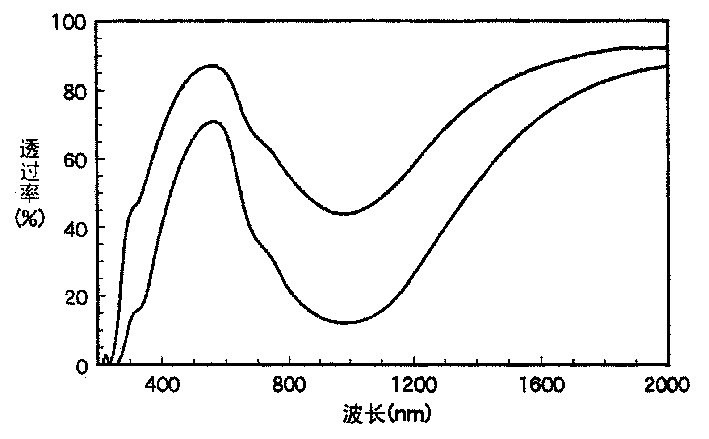

[0049] Dry mix the LaB with a V-blender 6 0.01 kg of powder A and 8.7 kg of ETFE (tetrafluoroethylene-ethylene copolymer) resin. Then, the mixture was sufficiently airtight mixed at 320° C. near the melting temperature of the ETFE resin, and the mixture was extruded at 320° C. to form a film with a thickness of about 50 μm. LaB in the film 6 Th...

Embodiment 2

[0055] With the LaB in embodiment 1 6 0.005kg of powder A and 8.7kg of PTFE resin were dry-mixed with a V-type mixer. Then, in the same manner as in Example 1, the mixture was sufficiently airtight mixed at 320° C. near the melting temperature of the ETFE resin, and the mixture was extruded at 320° C. to form a film with a thickness of about 50 μm. LaB in the film 6 The content of fine particles is equivalent to 0.05g / m 2 .

[0056] The obtained film-shaped heat insulating material was evaluated in the same manner as in Example 1. The visible light transmittance was 80% and the solar radiation transmittance was 65%. It blocks 35% of the direct incident light of the sun's rays and has a high thermal insulation effect. In addition, the transmittance in the ultraviolet region is 34% at a wavelength of 290nm and 43% at a wavelength of 320nm. This is the range in which bees etc. can have sufficient pollination activity. Furthermore, the base value is 4.1%, and the transparenc...

Embodiment 3

[0058] Except that PET (polyethylene terephthalate) resin was used instead of ETFE resin in Example 2, and the heating temperature was increased to the temperature at which PET was fully softened (about 300°C), the film was produced in the same way as in Example 2. . LaB in the film 6 The content of microparticles is the same as in Example 2, which is equivalent to 0.05g / m 2 .

[0059] The obtained film-shaped heat insulating material was evaluated in the same manner as in Example 1. The visible light transmittance was 79% and the sunlight transmittance was 65%. It blocks 35% of the direct incident light of the sun's rays and has a high thermal insulation effect. In addition, the transmittance in the ultraviolet region is 0% at a wavelength of 290nm and 35% at a wavelength of 320nm, and 0% at a wavelength of 290nm is due to the influence of PET resin as a resin base material. Furthermore, the base value is 2.5%, and the transparency is very high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average dispersed particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com