Process for continuous extraction of buckwheat starch, buckwheat protein, flavone, and dietary-fiber from buckwheat

A dietary fiber and buckwheat protein technology, which is applied in food science, food preparation, application, etc., can solve the problems of affecting the quality of buckwheat starch, large amount of dust in the production process, and high equipment cost, so as to improve vascular permeability and production efficiency High, the effect of inhibiting fat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

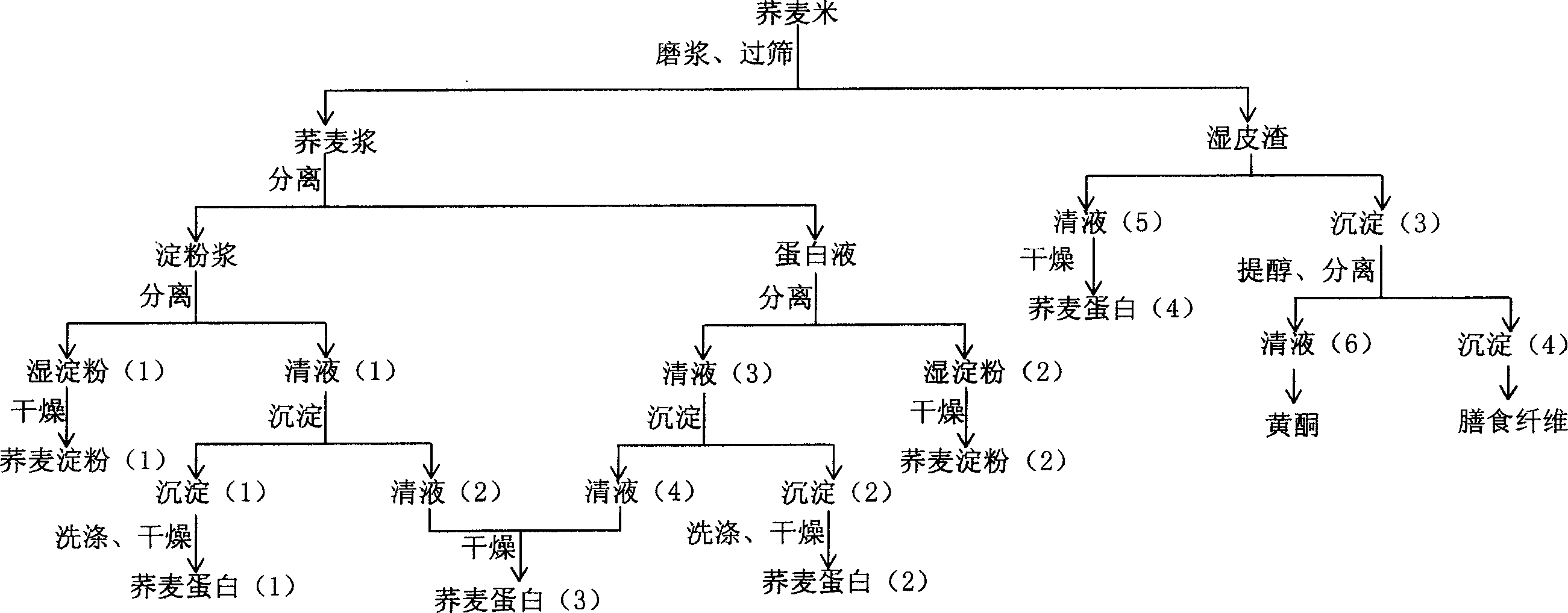

Method used

Image

Examples

example 1

[0025] 1. Soaking: Weigh 25 tons of sweet buckwheat rice, add 40 tons of water, and soak for 8 hours.

[0026] 2. Refining: Refining the soaked buckwheat rice through gold steel sand grinding. When refining, add an appropriate amount of water, and the total amount of water added is about 160 tons.

[0027] 3. Sieving: Sieve the buckwheat pulp through 8 horizontal stainless steel sieves of 80-150 mesh, and separate the skin dregs in the buckwheat pulp to obtain 160 tons of buckwheat pulp and 25 tons of skin dregs.

[0028] 4. Separation: Separate the buckwheat pulp through twelve cyclone separators to obtain 87 tons of starch slurry and 73 tons of protein liquid.

[0029] 5. Extract buckwheat starch (1): 87 tons of starch slurry is continuously passed through a horizontal screw centrifuge to obtain wet starch and supernatant (1). The diameter of the horizontal screw centrifuge drum: length ≥ 1: 4.0. The wet starch was air-dried to obtain 13.5 tons of buckwheat starch (1).

...

example 2

[0040] Take 25 tons of tartary buckwheat rice, according to the same process, process, can obtain 12.5 tons of wheat starch (1) from 25 tons of tartary buckwheat rice, 2.6 tons of buckwheat starch (2), the buckwheat protein ( 1) 128kg, buckwheat protein with a protein content greater than 75% (2) 202kg, buckwheat protein with a protein content greater than 70% (3) 745kg, buckwheat protein with a protein content greater than 65% (4) 258kg, flavonoids 72kg, dietary fiber 3.5 tons .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com