Protective slag for Austenic stainless steel plate wand crystallizer

A technology of mold powder and austenitic stainless steel, which is applied in the field of austenitic stainless steel slab mold powder, can solve the problems of high grinding loss rate, poor stability, and prone to depressions and cracks on the surface of the slab. Achieve the effects of reduced grinding loss, good stability and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For the austenitic stainless steel 0Cr18Ni9 slab produced by the applicant’s second steelmaking plant, the composition requirements of the finished steel product

[0034] C≤0.07% Si≤1.00% Mn≤2.0% P≤0.035%

[0035] S≤0.030% Cr≤17.0%-19.0% Ni≤8%-11%

[0036] The size of the billet is 200×1240mm 2 , In the process of continuous casting and steel drawing, the temperature of molten steel in the tundish is 1480°C-1505°C, and the casting speed is 0.75-0.95m / min. Using the austenitic stainless steel slab mold mold slag of the present invention, the slag basicity CaO / SiO 2 =1.36, melting point 1098°C, melting speed 30 seconds, viscosity 0.156pa.s, thermal conductivity of mold slag at 800°C is 0.124W / m.k, thickness of mold slag liquid slag layer in mold is 11-14mm, mold slag consumption is 0.48 kg / steel, the grinding loss rate of the cast slab before rolling is 1.24%.

[0037] The steps to process the base material are as follows:

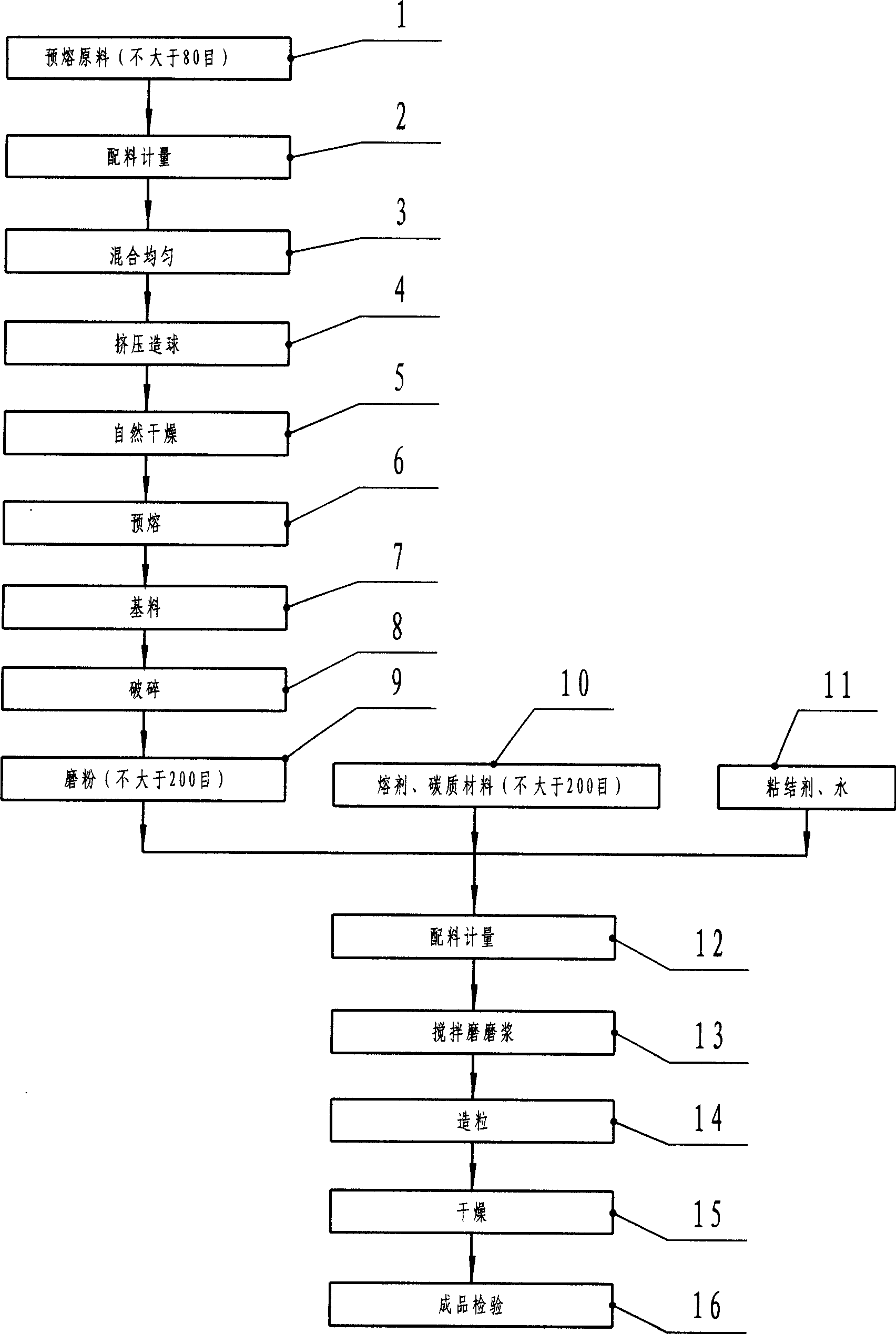

[0038] Pre-melted raw material 1, batching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com