Electret filter and process for producing the same

A manufacturing method and electret technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as difficulty in increasing surface charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

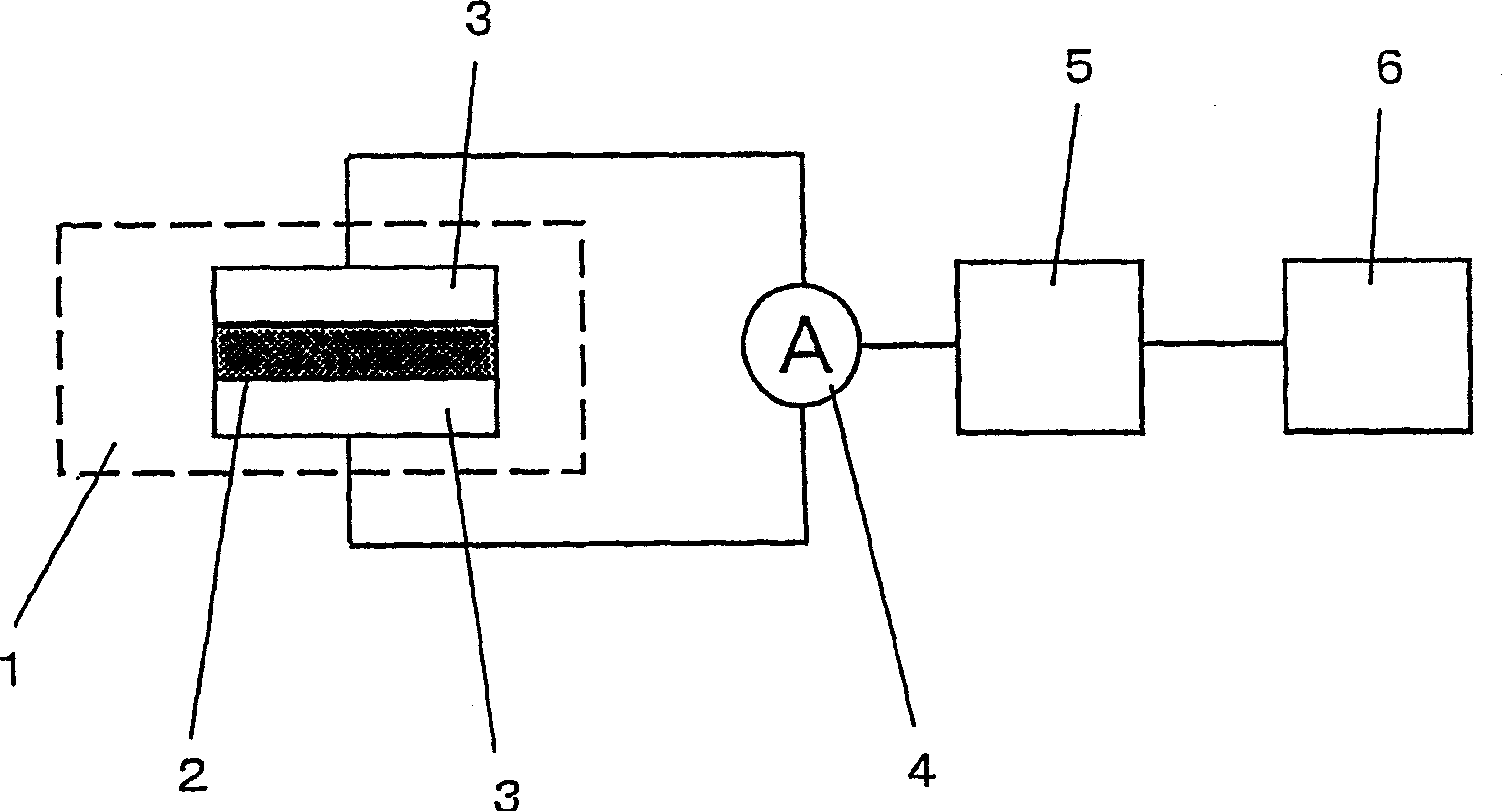

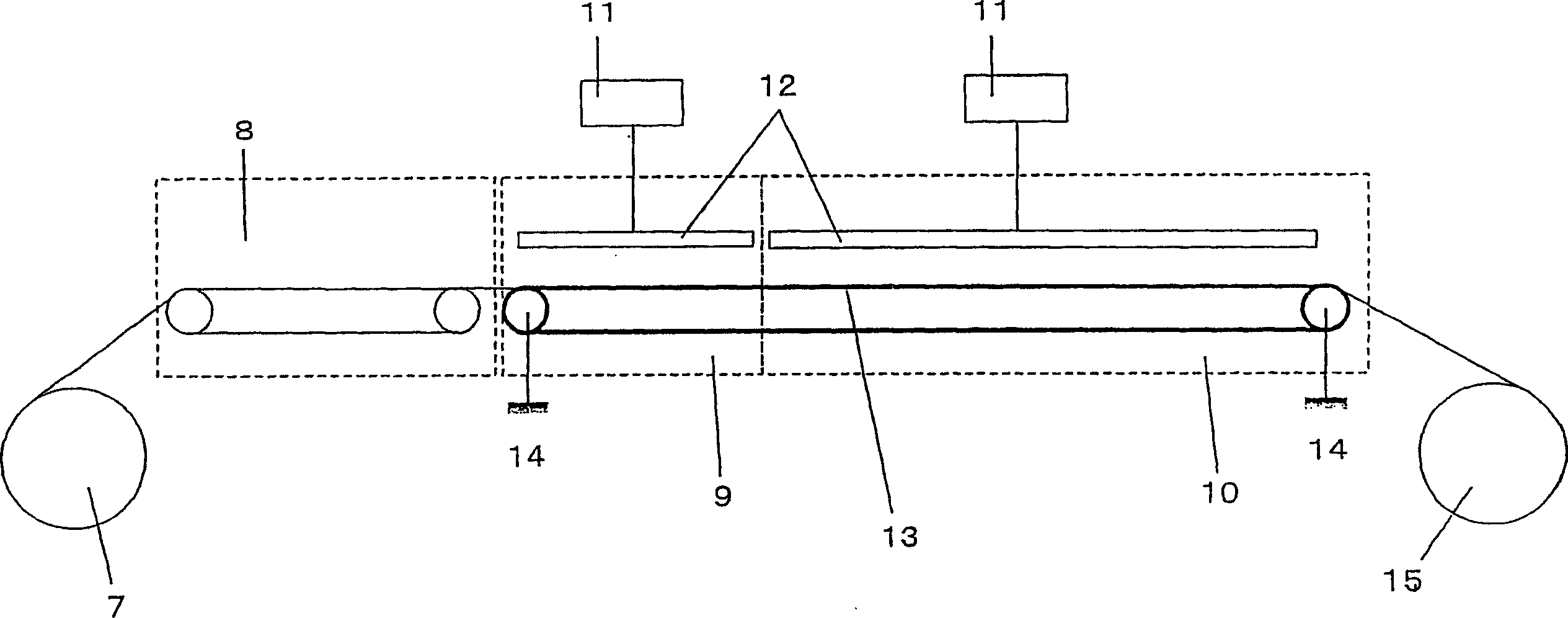

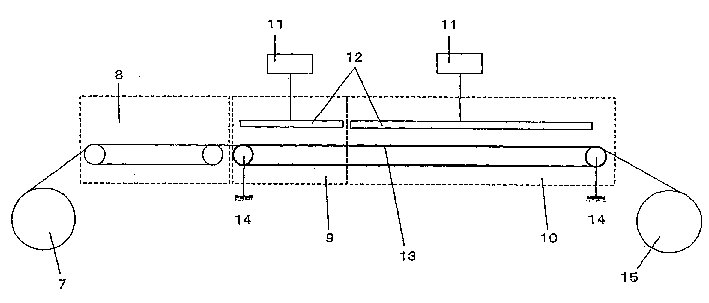

Method used

Image

Examples

manufacture example 1~8

[0065] Production examples 1 to 7 were obtained by varying the percentages in Table 1 using L-lactide and D-lactide as polymerization raw materials. This raw material was mixed with tin octoate and dodecanol as polymerization catalysts in a reaction vessel, and the inside of the vessel was replaced with nitrogen, then heated at 130° C. for 4 hours under reduced pressure to perform ring-opening polymerization. The reaction product was dissolved in chloroform, and the chloroform solution was diluted with hexane to perform purification by recrystallization. Table 1 shows the obtained resin characteristic values. In addition, in Production Example 1, the reaction product before recrystallization was taken out as Production Example 8.

[0066] [Determination of number average molecular weight]

[0067] The number average molecular weights of the polylactic acid polymers of Production Examples 1 to 8 were determined in terms of polystyrene by the GPC column method.

[0068] [Meas...

Embodiment 1

[0082] With the resin of manufacturing example 1, according to the melt blowing method, make eye pay (weight per unit area) 41g / m 2 , a nonwoven fabric with an average fiber diameter of 2.3 μm, and then, according to the method of charging treatment 1, the electret filter material sample of Example 1 was produced. The surface charge density, filtration characteristic evaluation, and heat of fusion of crystals were measured. Immediately after the measurement of the electrification treatment, and after holding at 25°C x 50RH% x one month, the filtration characteristics were measured respectively. Table 2 shows the results.

Embodiment 2

[0084] With the resin of manufacturing example 2, according to the melt blowing method, make eye pay (weight per unit area) 39g / m 2 , a nonwoven fabric with an average fiber diameter of 2.3 μm, and then, according to the method of charging treatment 1, the electret filter material sample of Example 2 was produced. The same evaluation as in Example 1 was performed. Table 2 shows the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com