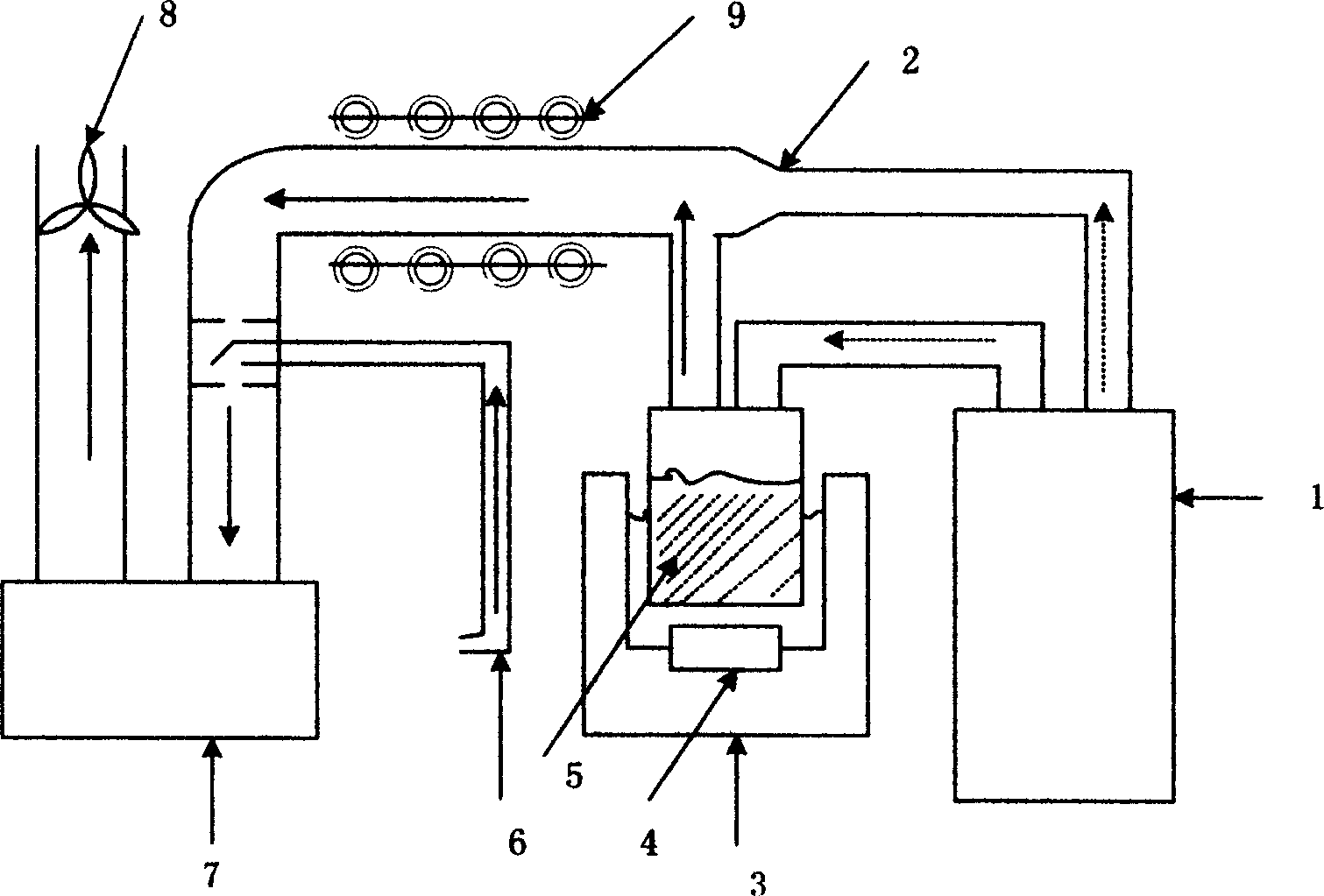

Preparation of multicomponent nano material by ultrasonic spray technology

A technology of nanomaterials and ultrasonic spraying, which is applied in the direction of spray evaporation, liquid separation into beads and granulation, etc. It can solve the problems of not being able to further obtain doped nanomaterials and single mass blocks, and achieve the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of SnO by Ultrasonic Spray Technology 2 -ZnO nanomaterials

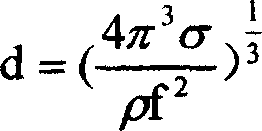

[0020] SnCl 4.5 h 2 O 0.5mol / L and zinc acetate 0.2mol / L were dissolved in 90ml of purified water, and 10ml of ethanol was added. Add a small amount of acetic acid to adjust the pH value to 5-7. Stir until there is no precipitate in the solution. Pour the prepared reaction precursor solution into a plastic container, and vibrate the reaction solution with an ultrasonic oscillator. Adjust the power of the ultrasonic oscillator so that the generated mist is larger. Use industrial oxygen as the carrier gas to carry the mist into the pipeline, so that the mist can undergo pyrolysis and oxidation reactions. The reaction temperature is between 300°C and 500°C, and an appropriate temperature is selected. The temperature is closely related to the fog concentration and the flow rate of the carried gas. By adjusting temperature, mist concentration and gas flow, SnO can be obtained 2 - ZnO...

Embodiment 2

[0021] Embodiment 2 prepares nanometer (NH 4 ) 3 SnCl 6 Material

[0022] SnCl 4.5 h 2 O 1mol / L and NH 4 F 0.8mol / L dissolved in 100ml ethanol. Stir until there is no precipitate in the solution. Pour the prepared reaction precursor solution into a plastic container, and vibrate the reaction solution with an ultrasonic oscillator. Adjust the power of the ultrasonic oscillator so that the generated mist is larger. Use industrial nitrogen as the carrier gas to carry the mist into the pipeline, so that the mist can undergo pyrolysis and oxidation reactions. The reaction temperature is between 250°C and 350°C, and an appropriate temperature is selected. SnCl 4.5 h 2 O contains 5 water molecules. In order to prevent the pyrolyzed oxygen from participating in the reaction, special attention should be paid to adjusting the gas concentration and flow rate so that the gas can quickly pass through the heating zone at an appropriate temperature. Deposited (NH 4 ) 3 SnCl 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com