Rare earth cascade extraction separation intelligence control system and method

An intelligent control system and intelligent control technology are applied in the field of intelligent control systems for rare earth cascade extraction and separation, which can solve the problems of large automation control surface, complex control process, and difficult control, so as to improve efficiency, reduce work intensity, and achieve good results. The effect of adaptability and openness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

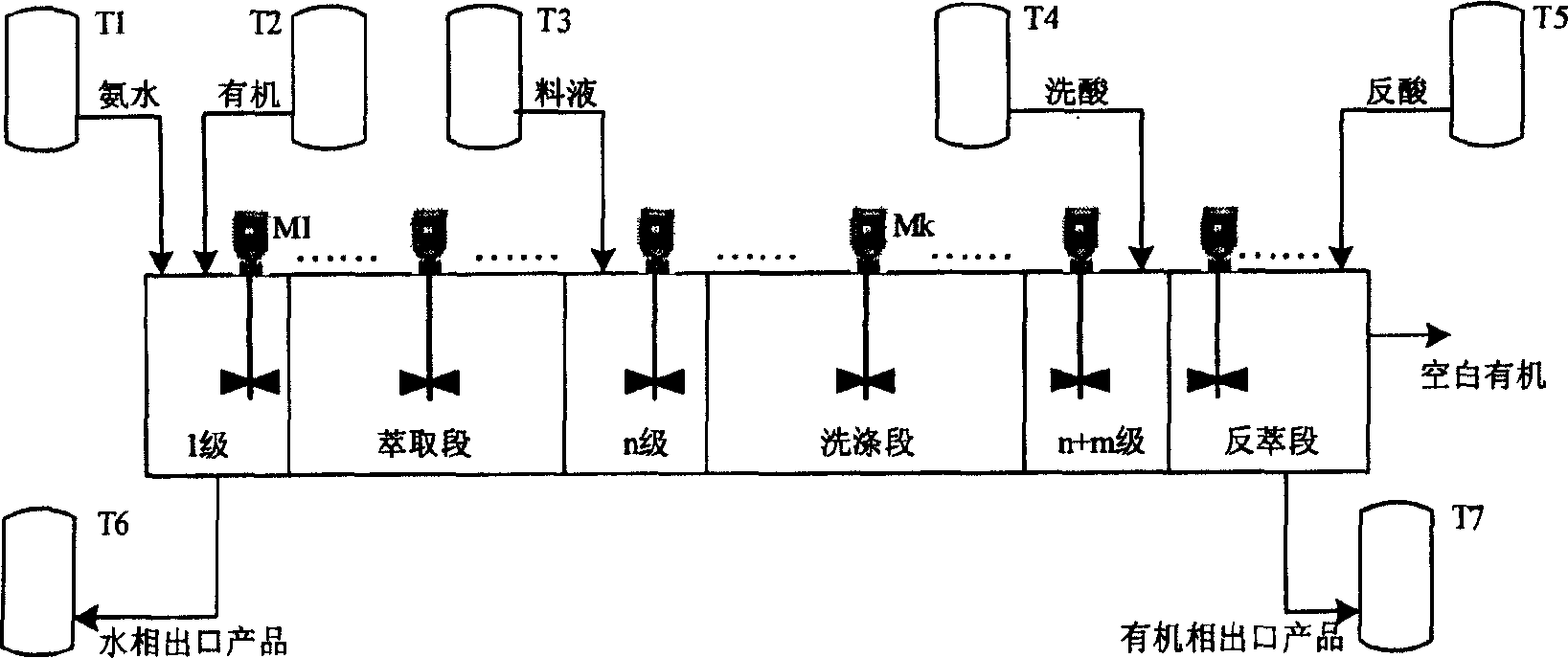

[0059] It is implemented on the production line of extraction, separation and extraction of yttrium.

[0060] There are 54 cascaded extraction tanks, 12 sets of 68 stirring motors, 5 flow meters, 5 metering pumps and 5 frequency converters on the production line, which constitute the on-site execution system.

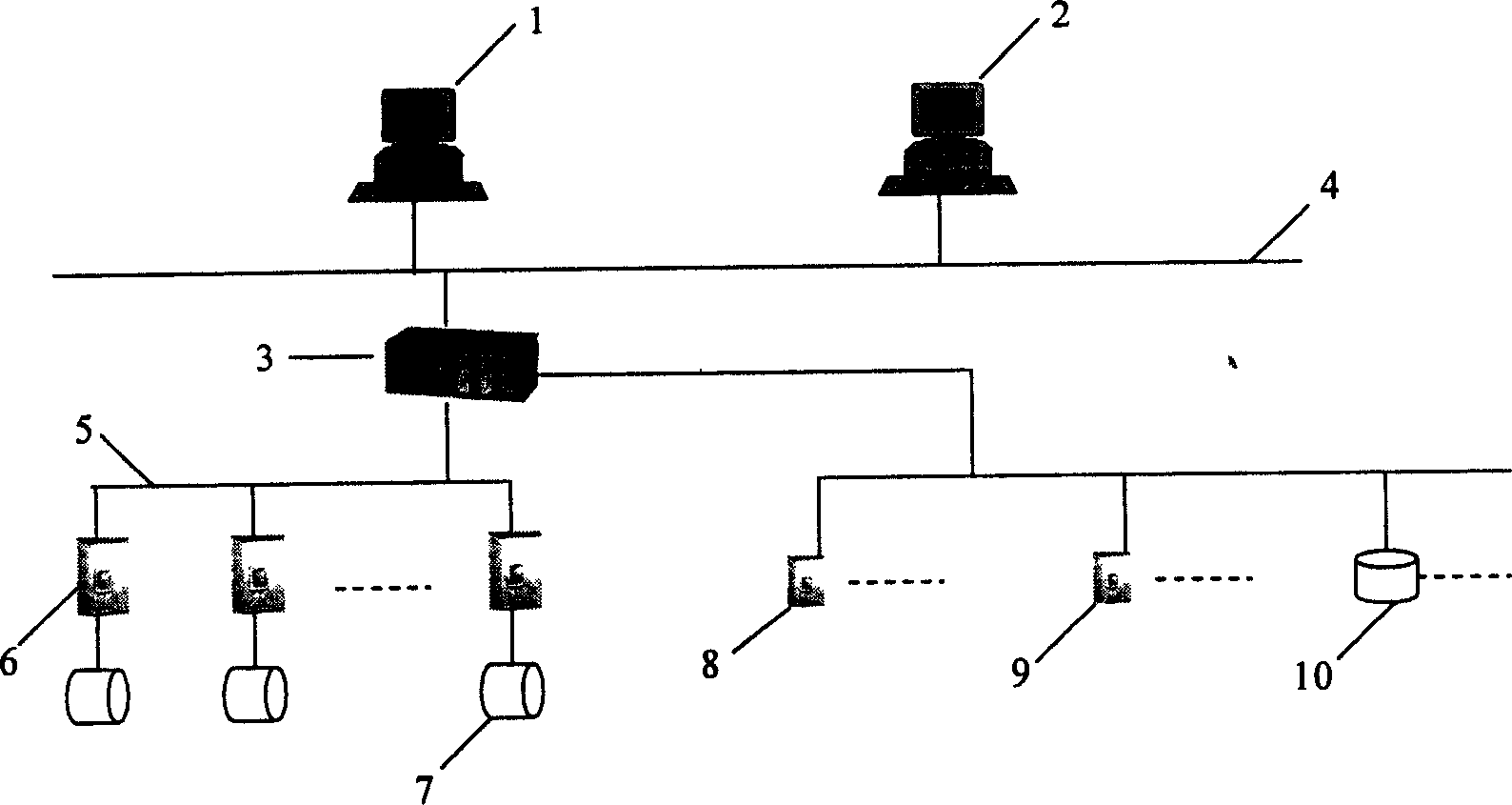

[0061] The present invention designs an operation station and a model station, both of which are connected by an object connection and embedded process control standard (hereinafter referred to as OPC) communication module, and are connected by a programmable logic controller (hereinafter referred to as PLC) through industrial Ethernet The network and the field bus network dedicated to high-speed data transmission between distributed devices are connected with the components of the field execution system.

[0062] Both the operation station and the model station are set in the centralized control room of the extraction production workshop. The computer of the operation...

Embodiment 2

[0102] Intelligent control system for cascade extraction and separation of rare earth cerium.

[0103] The intelligent control system such as Figure 10 shown. It has 54 stages of extraction tanks, 54 stirring motors, 5 flow meters, 5 metering pumps and 5 frequency converters, etc., which constitute the on-site actuators for extracting cerium.

[0104] Like the above embodiment, an operation station and a model station are also designed, and the interconnection between them and the connection between them and the on-site execution system are also adopted in the same manner as in Embodiment 1, and will not be repeated here.

[0105]In order to better ensure the safe operation of the system of the present invention, even if a failure can be discovered by the operator in time, it can be dealt with quickly and effectively. In addition, a set of multimedia monitoring system is added in the present embodiment. It is controlled by monitoring software, which consists of three parts...

Embodiment 3

[0121] An intelligent control system for cascade extraction and separation of rare earth praseodymium.

[0122] The intelligent control system can adopt such as image 3 or Figure 10 As shown, it has 54 extraction tanks, a total of 54 stirring motors; 5 flow meters and 5 frequency converters, etc., which constitute the on-site actuators for extracting cerium.

[0123] Like the above embodiment, an operation station and a model station are also designed, and the interconnection between them and the connection between them and the on-site execution system are also adopted in the same manner as in Embodiment 1, and will not be repeated here.

[0124] In order to better ensure the safe operation of the system of the present invention, even if a failure can be discovered by the operator in time, it can be dealt with quickly and effectively. In addition, a set of multimedia monitoring system is added in the present embodiment.

[0125]

[0126] Table 5 Cluster centers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com