Nondestructive testing method for every layer thin film thickness of SAW device with multilayer film structure

A measurement method and technology of film thickness, applied in the direction of electric/magnetic thickness measurement, measuring device, electromagnetic measuring device, etc., can solve the problem of non-destructive and accurate measurement of film thickness, difficulty in determining the value of relative permittivity ε, and large difference in film ε and other issues, to achieve the effect of low cost, improved performance, and simple measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

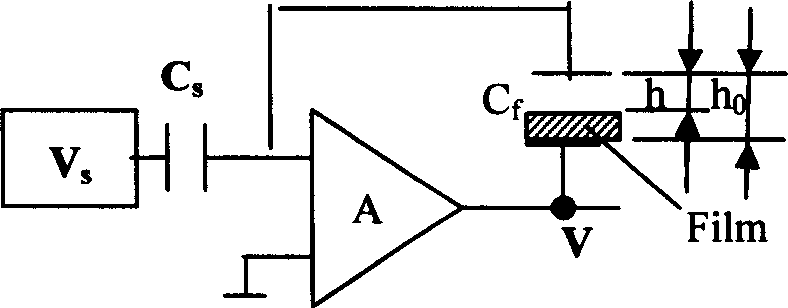

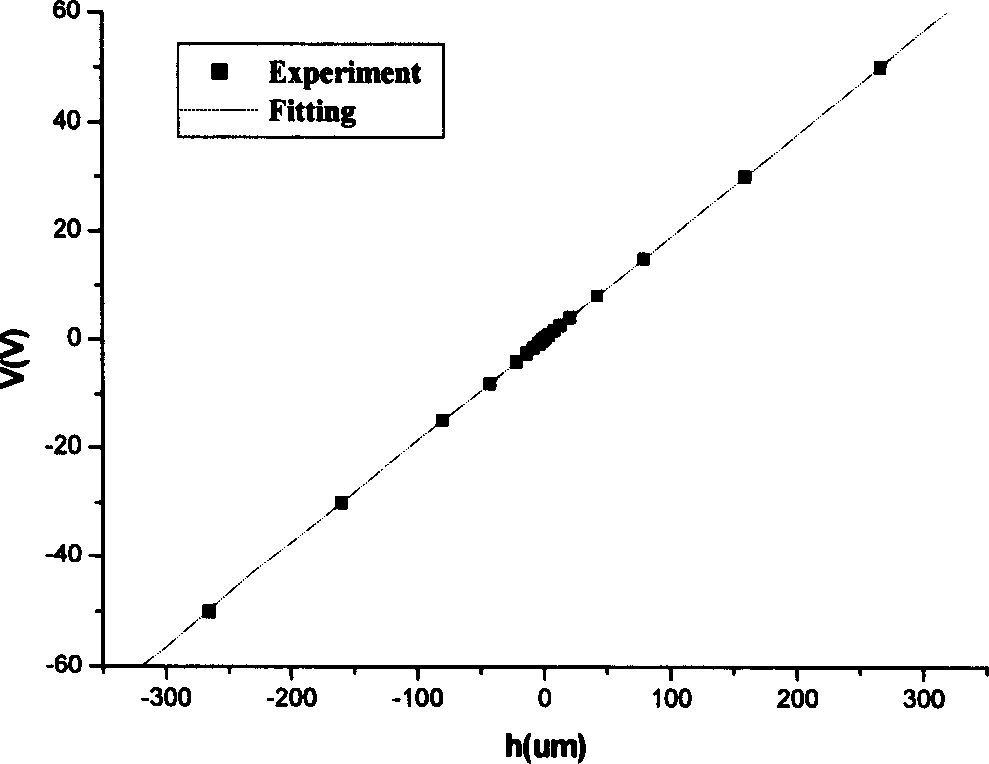

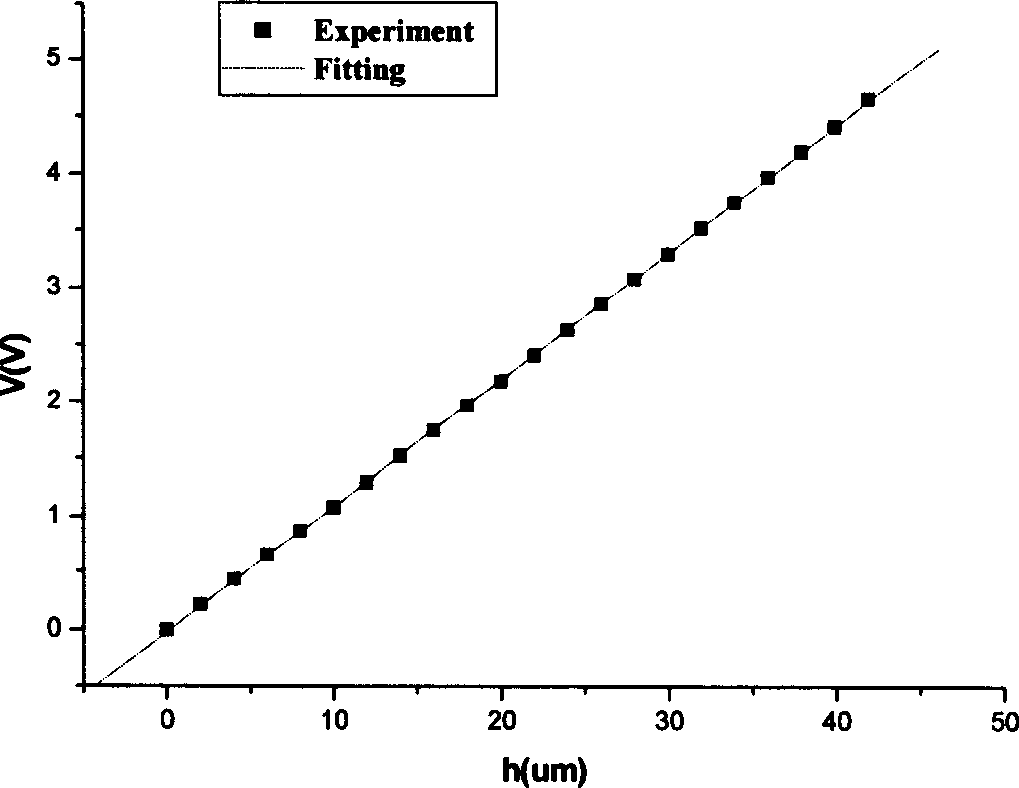

[0028] The present invention utilizes the upper and lower plate electrodes of the parallel plate capacitance micrometer to measure the variation between the two electrodes to measure the thickness of the sample film. The principle diagram is shown in figure 1 .

[0029] In the figure, A is an operational amplifier (Operational Amplifier), Vs is the square wave excitation oscillator signal source voltage, Cs is the standard capacitance (1pF), h is the upper and lower plate sensing capacitance C f The air gap between, V is the amplifier output voltage. The relationship between the operational capacitance sensor and the air gap h is as follows:

[0030] V = - ( C s V s ϵϵ 0 S ) h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com