Protease inhibitor

An inhibitor, cysteine protease technology, applied in the direction of protease inhibitors, transferrin, peptide/protein components, etc., can solve the problem of unknown lactoferrin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

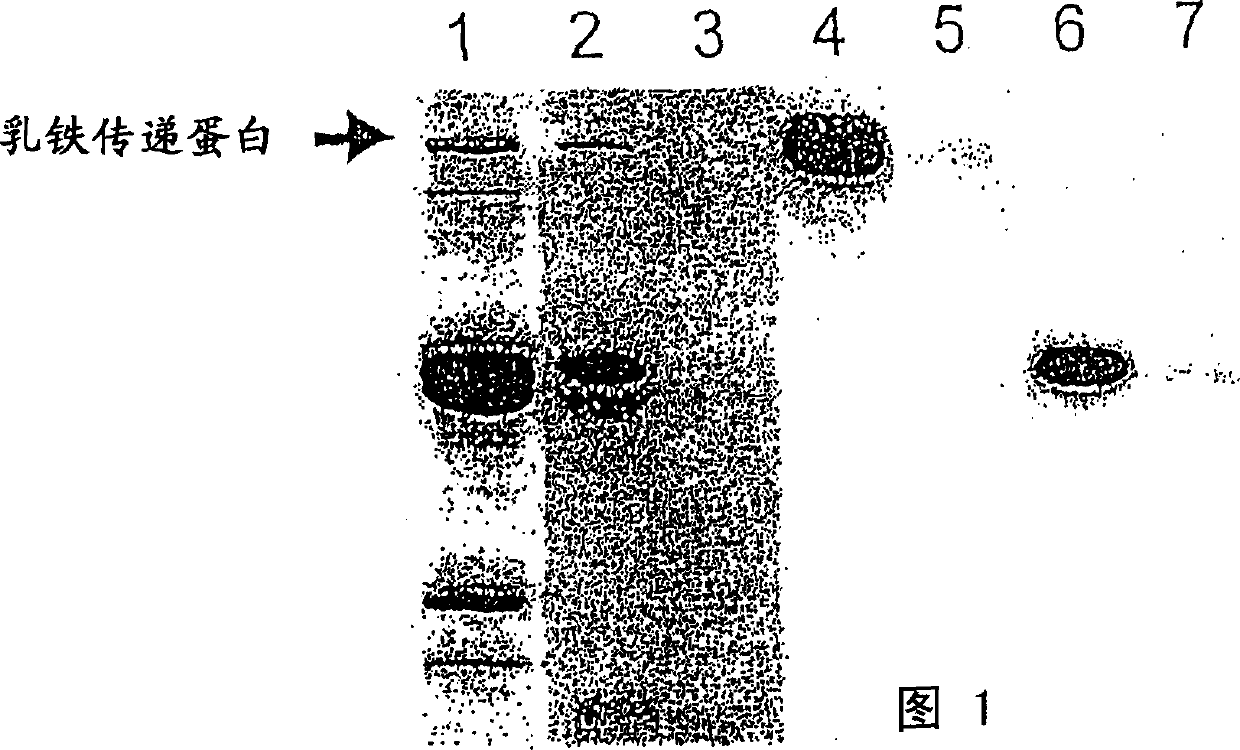

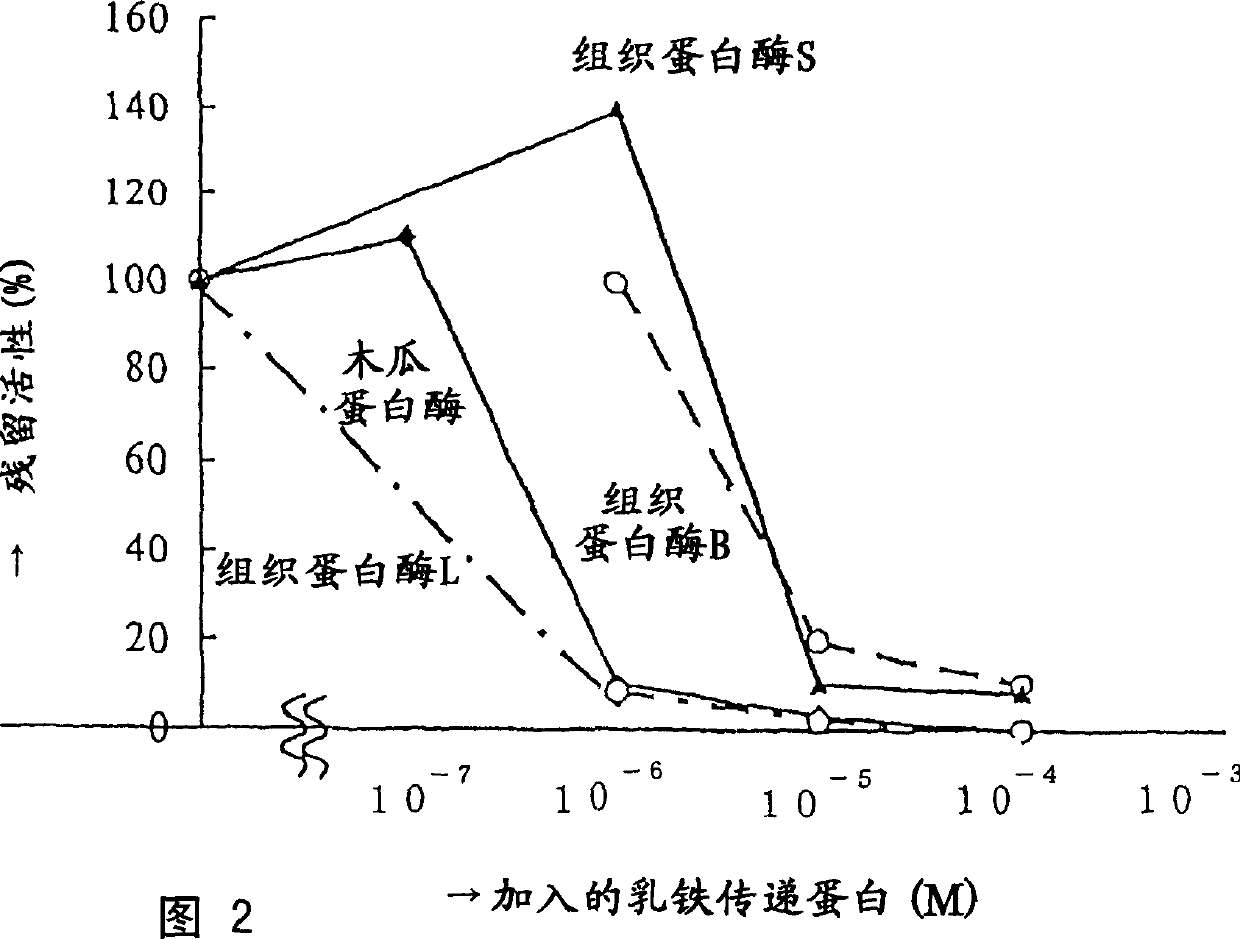

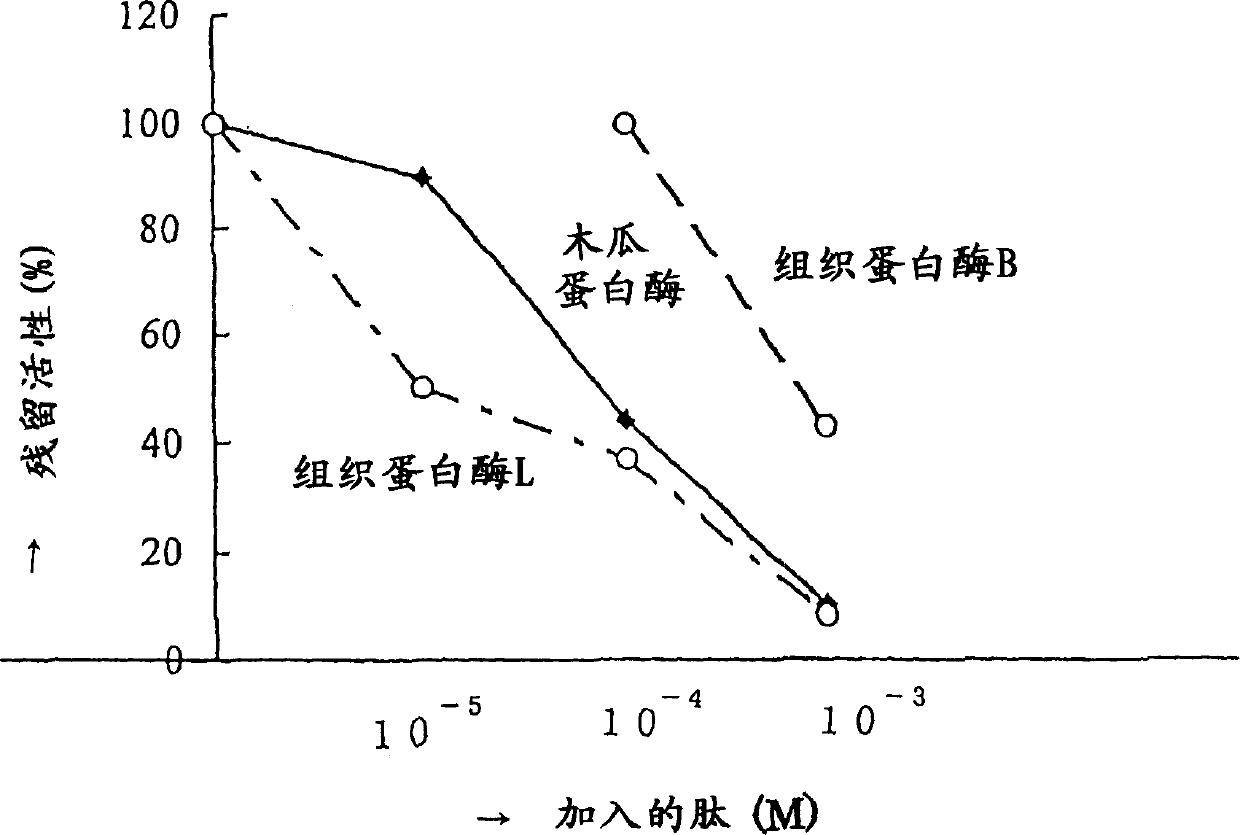

Image

Examples

Embodiment 1

[0156] The peptide having the amino acid sequence 679-695 of SEQ ID No. 1 in the sequence table was produced according to the following steps (Fig. 3, human lactoferrin peptide Y679-K695).

[0157] The above peptide of the present invention was produced by synthesis using an automated peptide synthesizer (manufactured by Applied Biosystems, Model 433A).

[0158] With N-methylpyrrolidone (product of Applied Biosystems, hereinafter abbreviated as NMP) containing 20% piperidine, the amino protecting group Fmoc- The group was cleaved and the resin was washed with NMP. Then, using the FastMoc (registered trademark) kit (product of Applied Biosystems) to make Fmoc-threonine [precisely, Fmoc-amino acid (product of Applied Biosystems) )] was condensed on the resin, and the resin was washed with NMP. The Fmoc group is then cleaved and Fmoc-alanine corresponding to the second amino acid at the C-terminal is condensed, followed by washing the resin. By further repeating the steps of...

Embodiment 2

[0162] (preparation of tablets formulated with lactoferrin)

[0163] Cystatin tablets containing the following compositions were produced as follows.

[0164] Bovine lactoferrin (product of Morinaga dairy company) 40.0%

[0165] Lactose (Morinaga Dairy Company product) 18.5%

[0166] Corn starch (Nisshin flour milling company product) 30.7%

[0167] Magnesium stearate (product of Taihei Chemical Industry Co., Ltd.) 1.4%

[0168] Carboxymethylcellulose calcium (Gotokn chemical company product) 9.4%

[0169] Add an appropriate amount of sterile purified water to knead the mixture of bovine lactoferrin, lactose, cornstarch and carboxymethylcellulose calcium), and dry the kneaded material at 50° C. for 3 hours. Magnesium stearate was then added to the obtained dry product and mixed uniformly, followed by tableting according to conventional procedures, thereby obtaining tablets.

Embodiment 3

[0171] (preparation of lactoferrin capsules)

[0172] With a 50-mesh sieve (product of Yamato Science Co., Ltd.), 600 g of lactose (product of Wako Pure Chemical Industry Co., Ltd.), 400 g of cornstarch (product of Nissnin Powder Milling Co., Ltd.), 400 g of crystalline cellulose (product of Wako Pure Chemical Industry Co., Ltd.) and 600 g One gram of bovine lactoferrin (product of Morinaga Dairy Company) was sieved, packed into a polyethylene bag with a thickness of 0.5 mm, and mixed up and down repeatedly. Using a fully automated capsule filling machine (manufactured by Cesere Pedini, press-fit type), the obtained powder is filled into capsules (Shionogi Qualicaps company product, No. 1 gelatin capsule, OP yellow No. 6 shell, empty weight 75 mg) with a capacity of 275 mg , thus obtaining 7000 capsules, each containing 82 mg of bovine lactoferrin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com