Alcohol soluble material in poly-fluorene group containing phosphate group in use for luminescent material

A phosphate group, alcohol-soluble technology, applied in the field of optoelectronic materials and information, can solve the problems of device aging, can not fundamentally solve aging and other problems, achieve high current efficiency, simple preparation method, high spectral stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

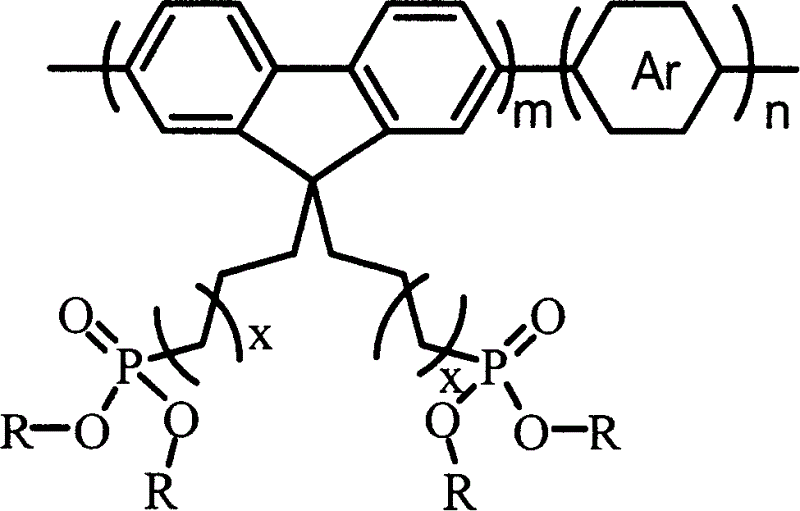

[0015] Embodiment 1: the application of poly[2,7-dibromo-9,9-(3'-phosphoethoxypropyl)fluorene]

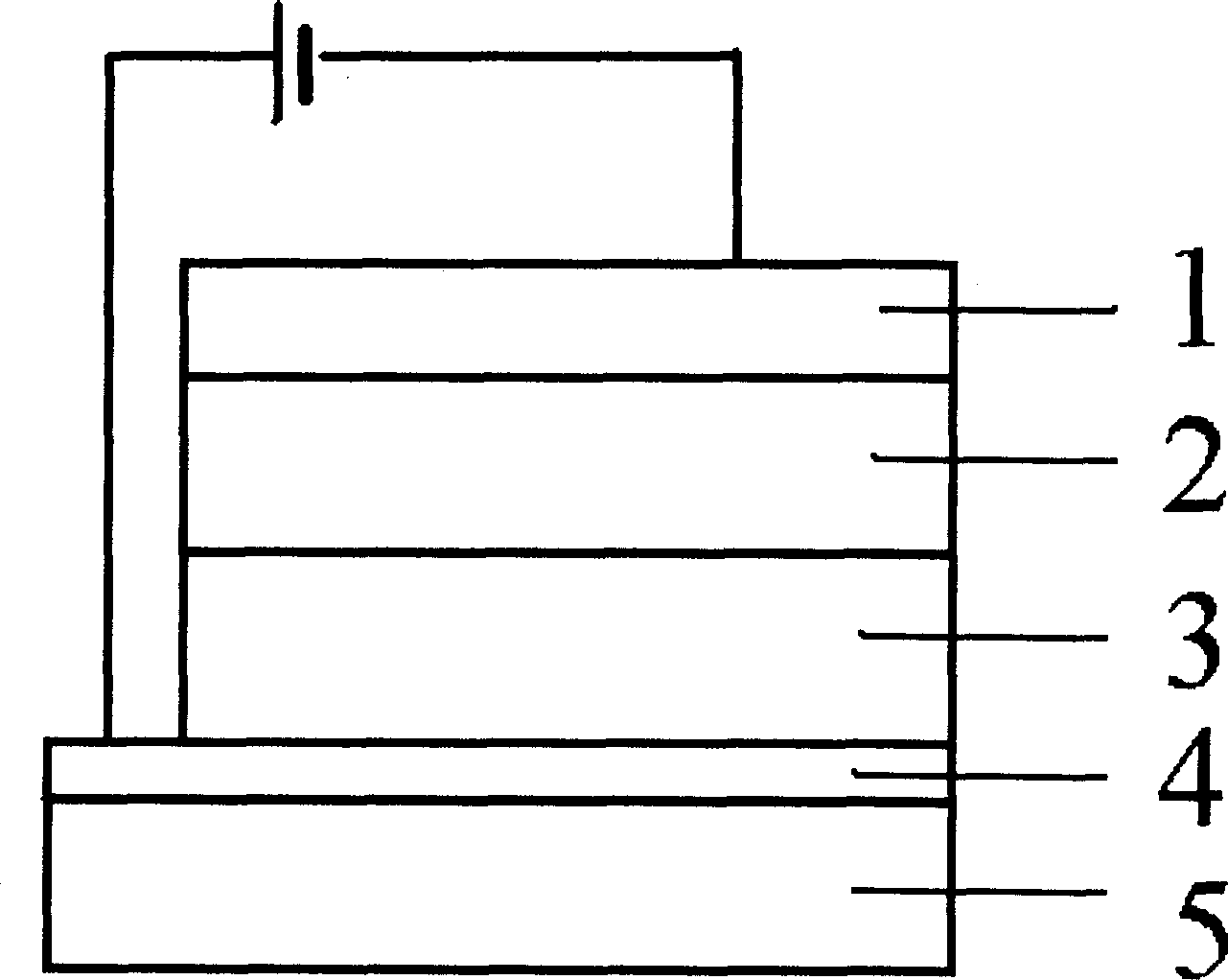

[0016] The basic structure of an electroluminescent (EL) device is as shown in Figure 1. The specific structure of this embodiment is: ITO / PEDOT / Polymer / Ca / Al, and its preparation process is: using pre-cleaned ITO (indium tin oxide ) glass as the anode, and then a layer of conductive polymer-polythiophene derivative (PEDOT) (50nm) was spin-coated at a speed of 3000 rpm. A chloroform solution of poly[2,7-dibromo-9,9-(3'-phosphoethoxypropyl)fluorene] (Polymer) with a concentration of 10 mg / mL was spin-coated on ITO at a speed of 1500 rpm. surface. Subsequently, at 10 -3 Under Pa vacuum conditions, 10nm metal calcium and 100nm metal aluminum are sequentially vapor-deposited. The performance of the single-layer electroluminescent device is as follows: start-up voltage 6.0V, maximum brightness 901cd / m 2 , the brightness is 100cd / m 2 The electroluminescence efficiency at the time is...

Embodiment 2

[0017] Embodiment 2: the application of poly[2,7-dibromo-9,9-(3'-phosphoethoxypropyl)fluorene]

[0018] The basic structure of an electroluminescent (EL) device is as shown in Figure 1. The specific structure of this embodiment is: ITO / PEDOT / Polymer / Ca / Al, and its preparation process is: using pre-cleaned ITO (indium tin oxide ) glass as the anode, and then spin-coat a layer of conductive polymer-polythiophene derivative (PEDOT) (45nm) at a speed of 3000 rpm. A chloroform solution of 10 mg / mL poly[2,7-dibromo-9,9-(3'-phosphoethoxypropyl)fluorene] (Polymer) was spin-coated on the ITO surface at a rotational speed of 1500 rpm. Subsequently, at 9×10 -4 Under Pa vacuum condition, 100° C. is treated for one hour, and after cooling, 10 nm of metallic calcium and 100 nm of metallic aluminum are sequentially vapor-deposited. The performance of the single-layer electroluminescent device is as follows: start-up voltage 5.0V, maximum brightness 1279cd / m 2 , the brightness is 100cd / m ...

Embodiment 3

[0019] Embodiment 3: the application of poly[2,7-dibromo-9,9-(3'-phosphoethoxypropyl)fluorene]

[0020] The basic structure of an electroluminescent (EL) device is as shown in Figure 1. The specific structure of this embodiment is: ITO / PEDOT / Polymer / Ca / Al, and its preparation process is: using pre-cleaned ITO (indium tin oxide ) glass as the anode, and then spin-coat a layer of conductive polymer-polythiophene derivative (PEDOT) (55nm) at a speed of 3000 rpm. A 10 mg / mL ethanol solution of poly[2,7-dibromo-9,9-(3'-phosphoethoxypropyl)fluorene] (Polymer) was spin-coated on the ITO surface at a rotational speed of 1500 rpm. Subsequently, at 4×10 -4 Under the vacuum condition of Pa, metal calcium of 10 nm and metal aluminum of 100 nm are successively vapor-deposited. The performance of the single-layer electroluminescent device is as follows: the starting voltage is 4.5V and the maximum brightness is 520cd / m 2 , the brightness is 100cd / m 2 The electroluminescent efficiency is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brightness | aaaaa | aaaaa |

| Maximum brightness | aaaaa | aaaaa |

| Maximum brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com