Method for modifying lithium ion battery cathode

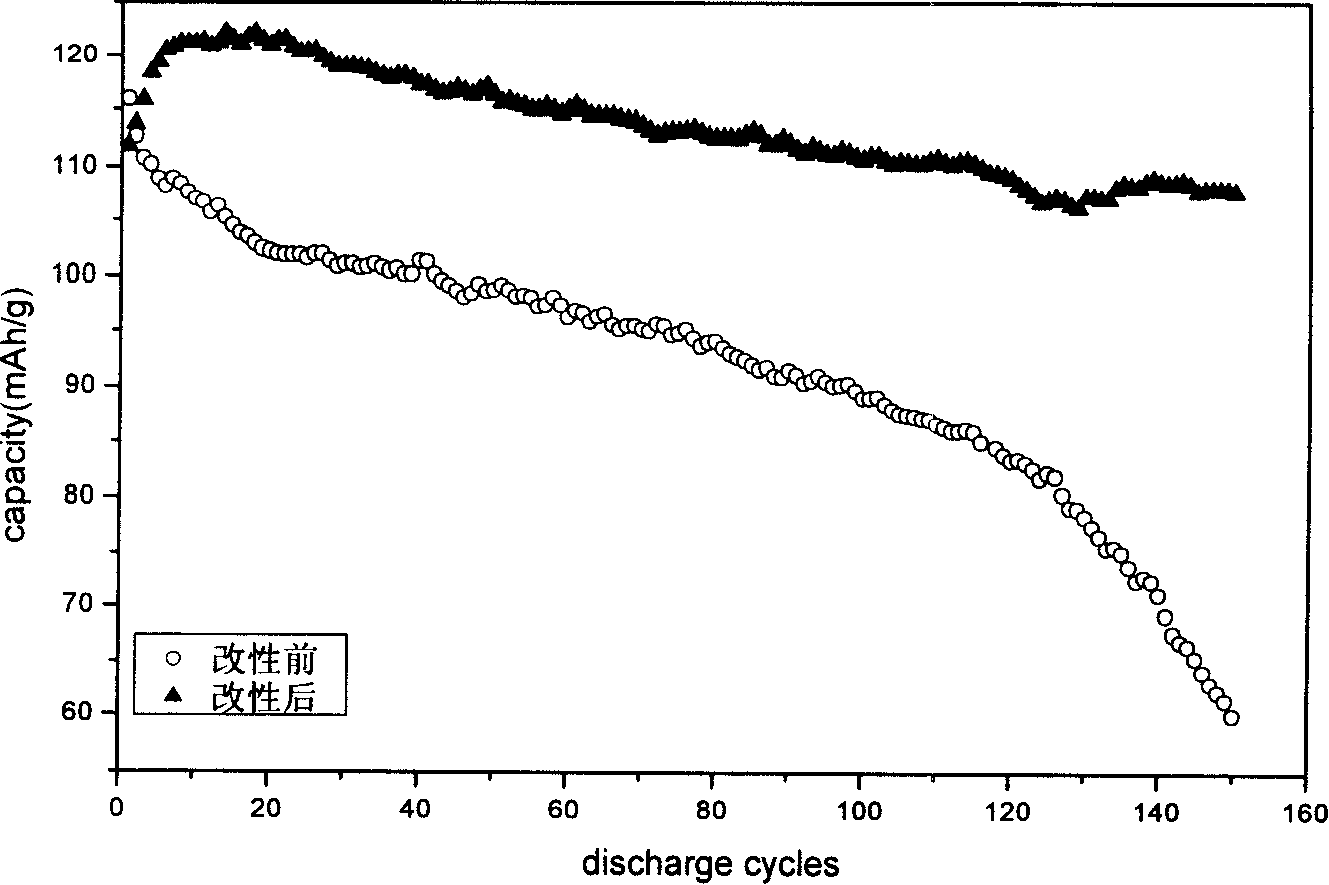

A lithium-ion battery and cathode technology, applied in electrode manufacturing, secondary batteries, circuits, etc., can solve problems such as negative discharge characteristics of the cathode, and achieve the effects of improving cycle performance, increasing discharge current, and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: at first sodium p-toluenesulfonate, p-toluenesulfonic acid and pyrrole are dissolved in water by making the p-methylbenzenesulfonate containing 0.5mol / L, 0.01mol / L p-methyl The mixed solution of benzenesulfonic acid and 0.05mol / L pyrrole; Then LiMn 2 o 4 , conductive carbon black and polyvinylidene fluoride are mixed in the mass ratio of 65:20:15 to make a mixture, and the mass concentration of the mixture obtained by adding 1-methyl 2-pyrrolidone solvent into the mixture is 50% slurry; Coat the slurry with a thickness of 100 μm on the aluminum foil and dry it to prepare the lithium-ion battery cathode. 2 Polymerization at low temperature for 60 seconds, cleaning the surface of the electrode with deionized water, and heat treatment at 60°C for 48 hours.

Embodiment 2

[0016] Embodiment 2: first sodium p-toluenesulfonate, p-toluenesulfonic acid and pyrrole are dissolved in water to make the p-toluenesulfonate containing 0.01mol / L, 0.3mol / L p-toluene Sulfonic acid and 0.4mol / L pyrrole mixture; then LiCoO 2 , conductive carbon black and polytetrafluoroethylene are mixed in the mass ratio of 90:5:5 to form a mixture, and the mass concentration of the mixture obtained by adding 1-methyl 2-pyrrolidone solvent into the mixture is 80% slurry; Coat the slurry with a thickness of 1000 μm on the aluminum foil and dry to prepare the lithium-ion battery cathode. 2 Polymerization at low temperature for 300 seconds, cleaning the surface of the electrode with deionized water, and heat treatment at 150°C for 18 hours.

Embodiment 3

[0017] Embodiment 3: at first sodium p-toluenesulfonate, p-toluenesulfonic acid and pyrrole are dissolved in water to make the p-toluenesulfonate containing 0.3mol / L, 0.5mol / L p-toluene Sulfonic acid and 0.1mol / L pyrrole mixture; then LiNiO 2 , conductive carbon black and polyvinylidene fluoride are mixed in the mass ratio of 80:7:13 to form a mixture, and the mass concentration of the mixture obtained by adding 1-methyl 2-pyrrolidone solvent to the mixture is 60% slurry; Coat the slurry with a thickness of 400 μm on the aluminum foil and dry to prepare the lithium-ion battery cathode. 2 Polymerization at low temperature for 150 seconds, cleaning the surface of the electrode with deionized water, and heat treatment at 300°C for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com