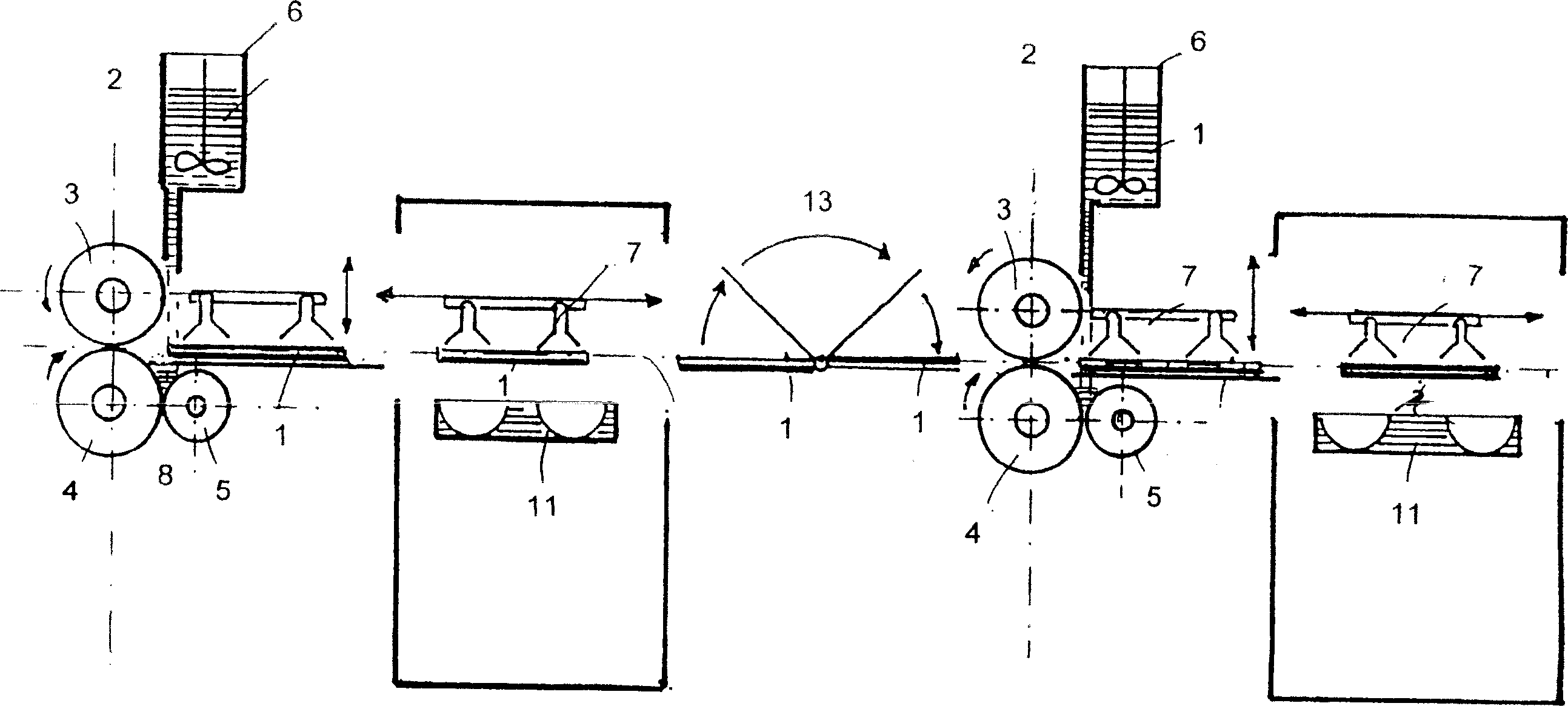

Method and device for coating printed boards with solder stop lacquers and galvanoresists that can be laser-structured and thermally hardened

A technology for printed circuit boards, solder blocking, applied in the secondary treatment of printed circuits, devices for applying liquid to surfaces, coatings, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

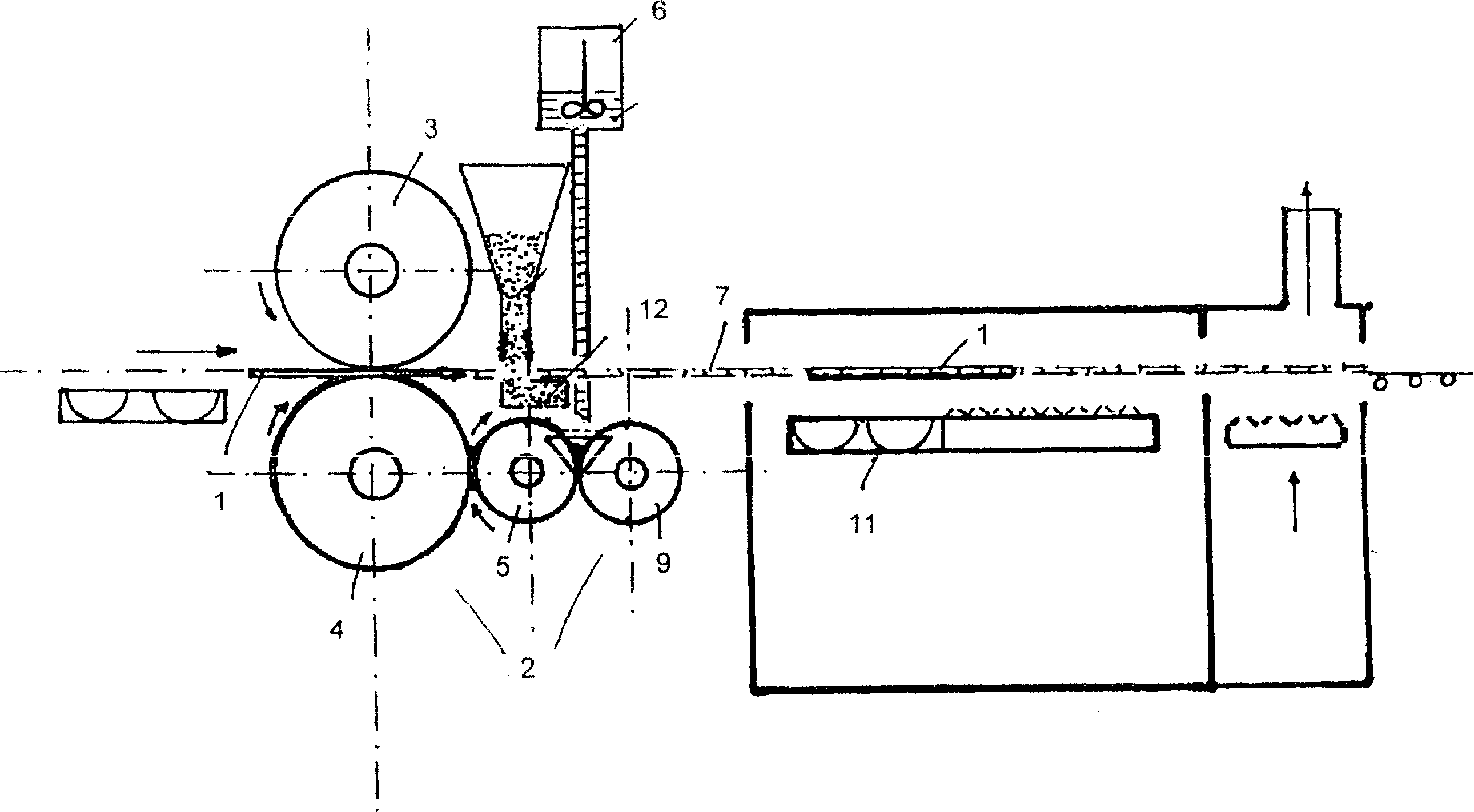

Method used

Image

Examples

example 1

[0036] Printed circuit board: 300×420×1.5mm, according to the FR4 type of NEMA (National Electronics Manufacturing Association), the maximum conductor height is 100 μm, and the conductor width is 150 μm.

[0037] Solder barrier varnish: 100 parts by weight of Probimer 65 Fa.Vantico AG + 5 parts by weight of γ-butyrolactone.

[0038] Roll coating device: RC Fa.Bürkle, rubberization: 100mm, Shore hardness A30, Rz 5μm;

[0039] Nip width: 100μm;

[0040] Wet coating: 50 μm.

[0041] Speed: 2m / min;

[0042] Infrared radiator: the wavelength of the first radiator is 2 μm, and the wavelength of the second radiator is 4 μm;

[0043] Circulating air temperature: 120°C;

[0044] Dryer length: 4m.

[0045] result:

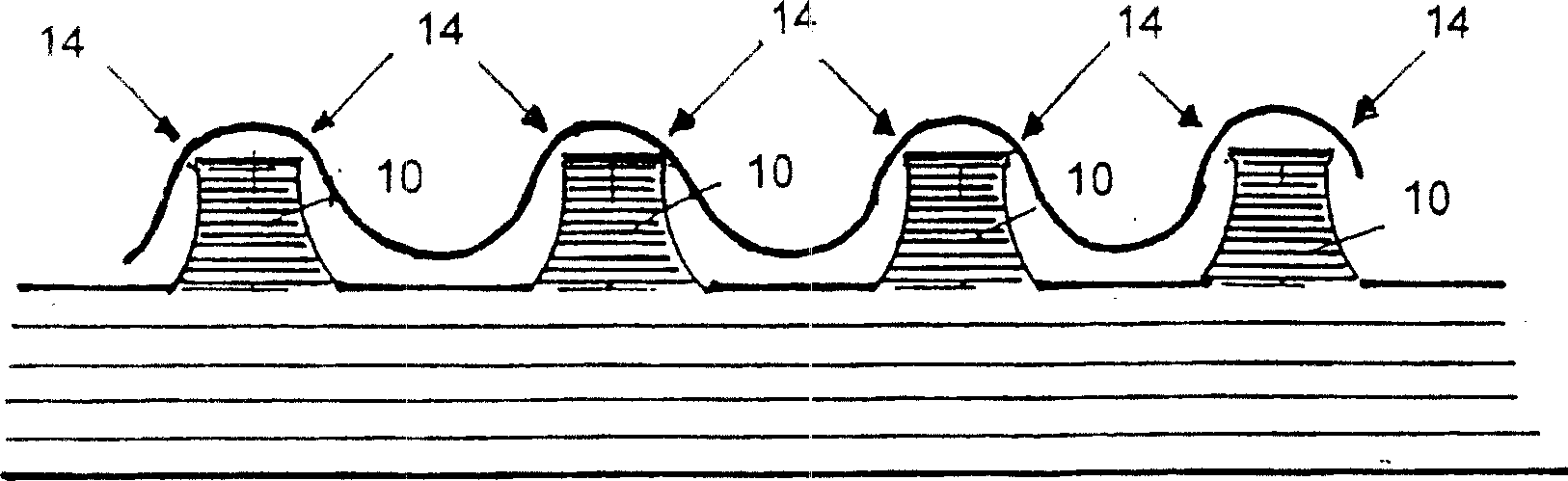

[0046] Dry film thickness: 30μm;

[0047] At a conductor height of 100 μm, edge coverage: 11 μm;

[0048] Pore diameter 300 to 1000 μm: No varnish.

example 2

[0050] Printed circuit board (2): 300×420×1.5mm, according to NEMA FR 4 type, the maximum conductor height is 100μm, and the conductor width is 150μm;

[0051] Solder barrier varnish (1): 125 parts by weight of Rütapox VE3746 contained in 80% by weight in ethylene glycol monomethyl ether, Fa. Bakelite AG; 0.5 parts by weight of 2-ethyl-4-methylimidazole Fa .BASF.

[0052] Viscosity: 9500mPas at 25°C;

[0053] TG after curing for one hour at 160°C: 155°C.

[0054] Roll coating device: RC Fa.Bürtle, rubberization: 100mm;

[0055] Hardness: Shore A30, Rz 5μm;

[0056] Nip width: 100μm;

[0057] Wet coating: 50 μm.

[0058] Speed: 2m / min. Infrared radiator: the wavelength of the first radiator is 2 μm, and the wavelength of the second radiator is 4 μm.

[0059] Circulating air temperature: 120°C;

[0060] Dryer length: 4m;

[0061] Cured at 160°C for 1 hour.

[0062] Coating Results:

[0063] Dry film thickness: 30μm;

[0064] At a conductor height of 100 μm, edge cove...

example 3

[0071] Printed circuit board: 300×420×1.5mm. According to NEMA's FR4 type, the maximum conductor height is 100 μm, and the conductor width is 10 μm.

[0072] Solder barrier varnish: 80.0 parts by weight of EPOSID VP868-2, 70% by weight, Duroplast-Chemie;

[0073] 19.5 parts by weight of HAT 9490 Kresolnovolak, 100% by weight, Fa.Vantico;

[0074] 0.5 parts by weight of 2-ethyl-4-methylimidazole Fa.BASF;

[0075] A total of 100 parts by weight, 75% by weight.

[0076] Viscosity: 7500 mPas at 25°C; TG after curing for 1 hour at 160°C: 150°C.

[0077] Roll coater: RC Fa.Robert Bürkle GmbH Freudenstadt;

[0078] Rubberization: 100mm;

[0079] Hardness: Shore A30, Rz 5μm;

[0080] Nip width: 120μm;

[0081] Wet coating: 50μm;

[0082] Transfer: 42% by volume.

[0083] Speed: 2m / min;

[0084] Infrared radiator: the wavelength of the first radiator is 2 μm, and the wavelength of the second radiator is 4 μm;

[0085] Circulating air temperature: 120°C;

[0086] Dryer lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com