Real-time detecting apparatus

A real-time detection and image sensing technology, applied in measuring devices, optical testing flaws/defects, instruments, etc., it can solve the problem that the reflection angle of the CCD camera cannot be adjusted in time, the detection capability of the testing equipment cannot be optimized, and it is difficult to obtain clarity. image and other problems, to achieve the effect of volume reduction, fast modulation speed, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

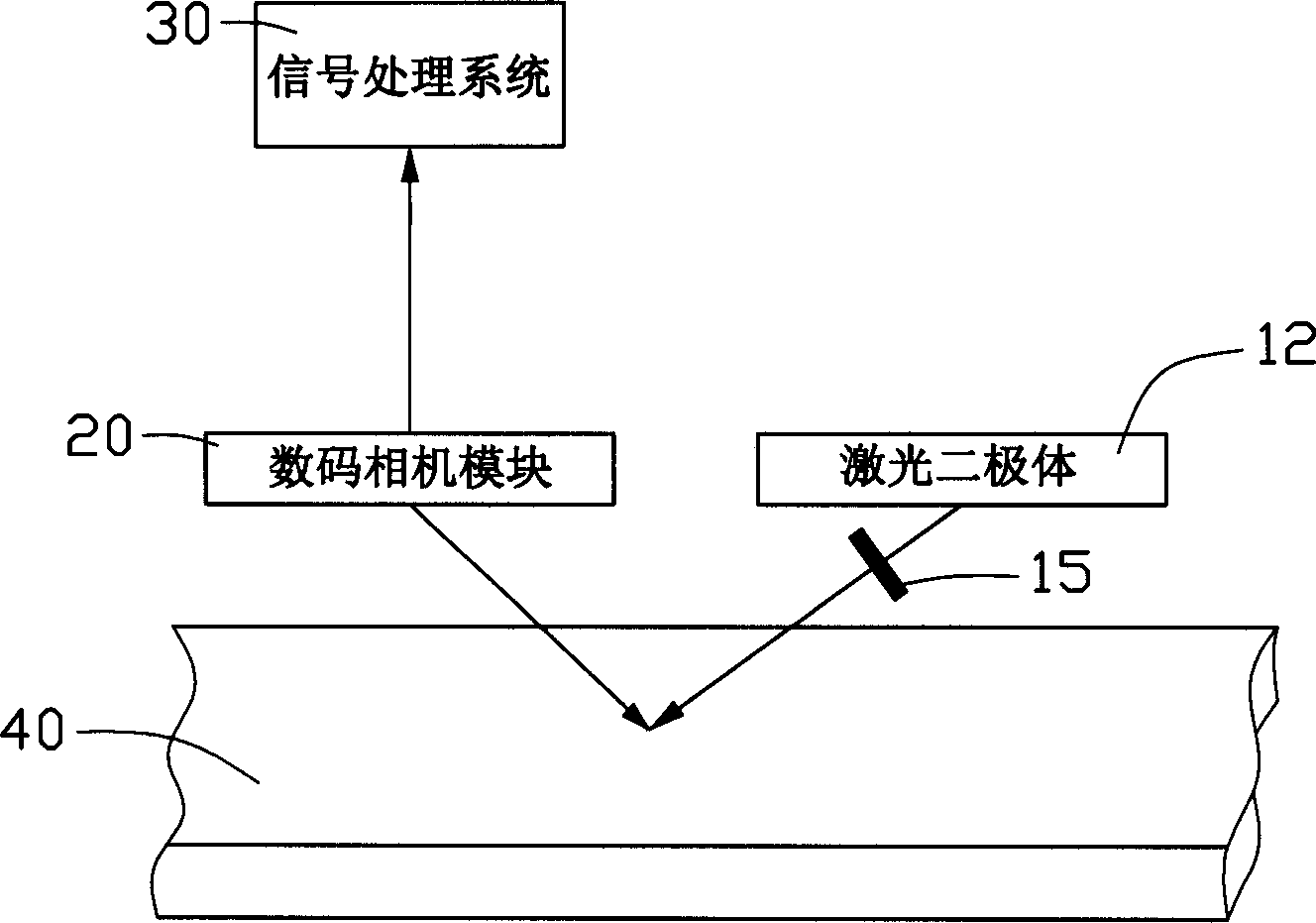

[0012] see figure 1 The real-time detection device of the present invention includes a laser diode 12 as a light source, a digital camera module 20, and a signal processing system 30, wherein a grating 15 is arranged on the optical path direction of the laser diode 12. The laser beam passing through the laser diode 12 is irradiated onto the substrate 40 , and the beam reflected by the substrate 40 is imaged by the digital camera 20 and sent to the signal processing system 30 for analysis and judgment.

[0013] The wavelength range of the laser diode 12 is 400nm-700nm, preferably 650nm, 405nm or any one shorter than the wavelength of blue light. In terms of light source, the output power is high, the modulation speed is fast, and the luminous angle is concentrated.

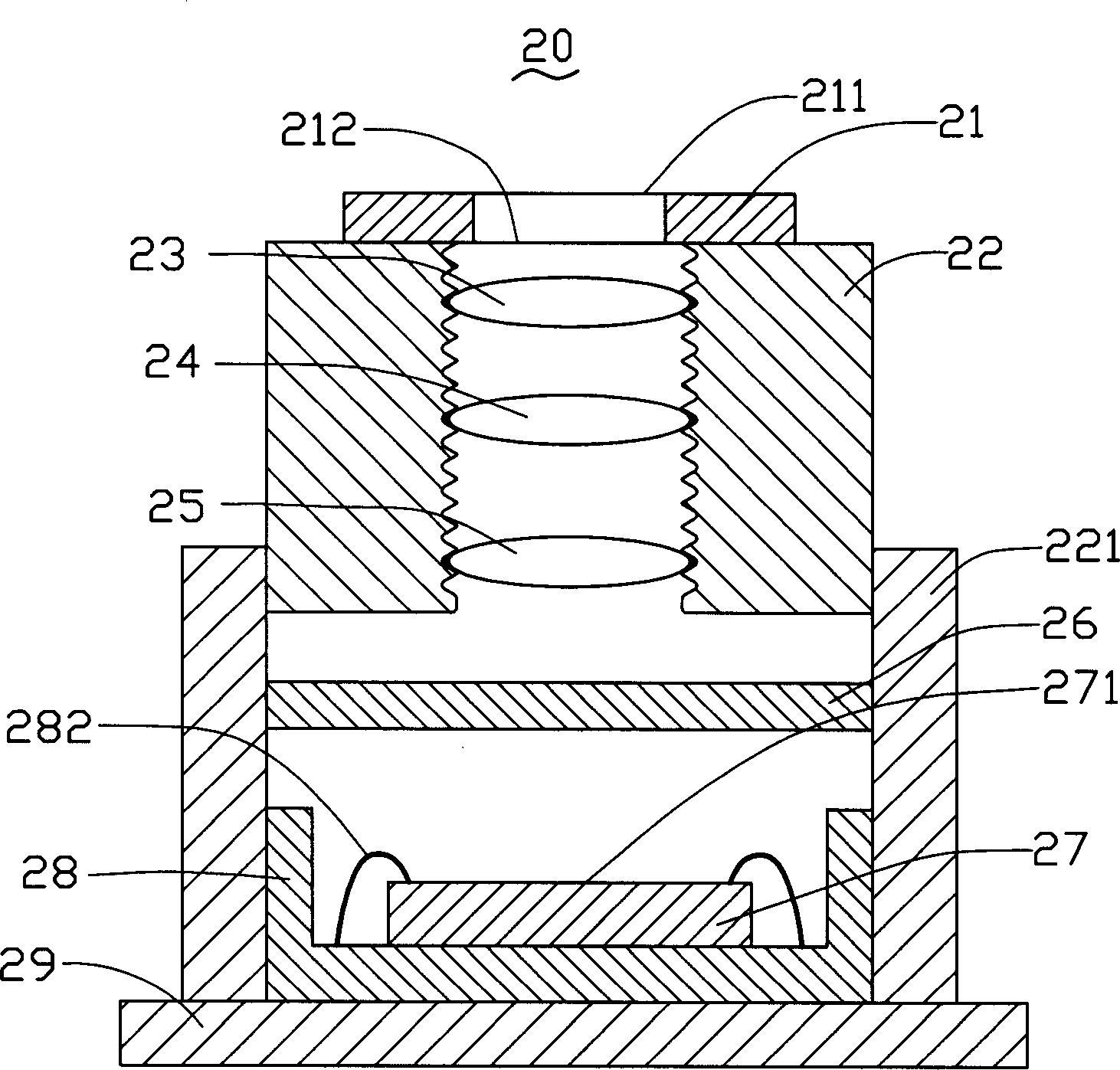

[0014] Please refer to the figure 2 The digital camera module 20 of the real-time detection device of the present invention includes a top cover 21, a lens barrel 22, a first lens 23, a second lens 24, a third l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com