Method and apparatus for producing calcium ammonium nitrate using by-product calcium nitrate of nitrate phosphatic fertilizer

A technology of calcium ammonium nitrate and phosphate nitrate fertilizer, which is applied in the direction of fertilization equipment, ammonium nitrate fertilizer, nitrogen fertilizer, etc. It can solve the problems that calcium ammonium nitrate cannot be directly used in granulation production, and the physical and chemical properties of calcium ammonium nitrate are greatly different from urea, so as to achieve product performance. Excellent, not easy to agglomerate, large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

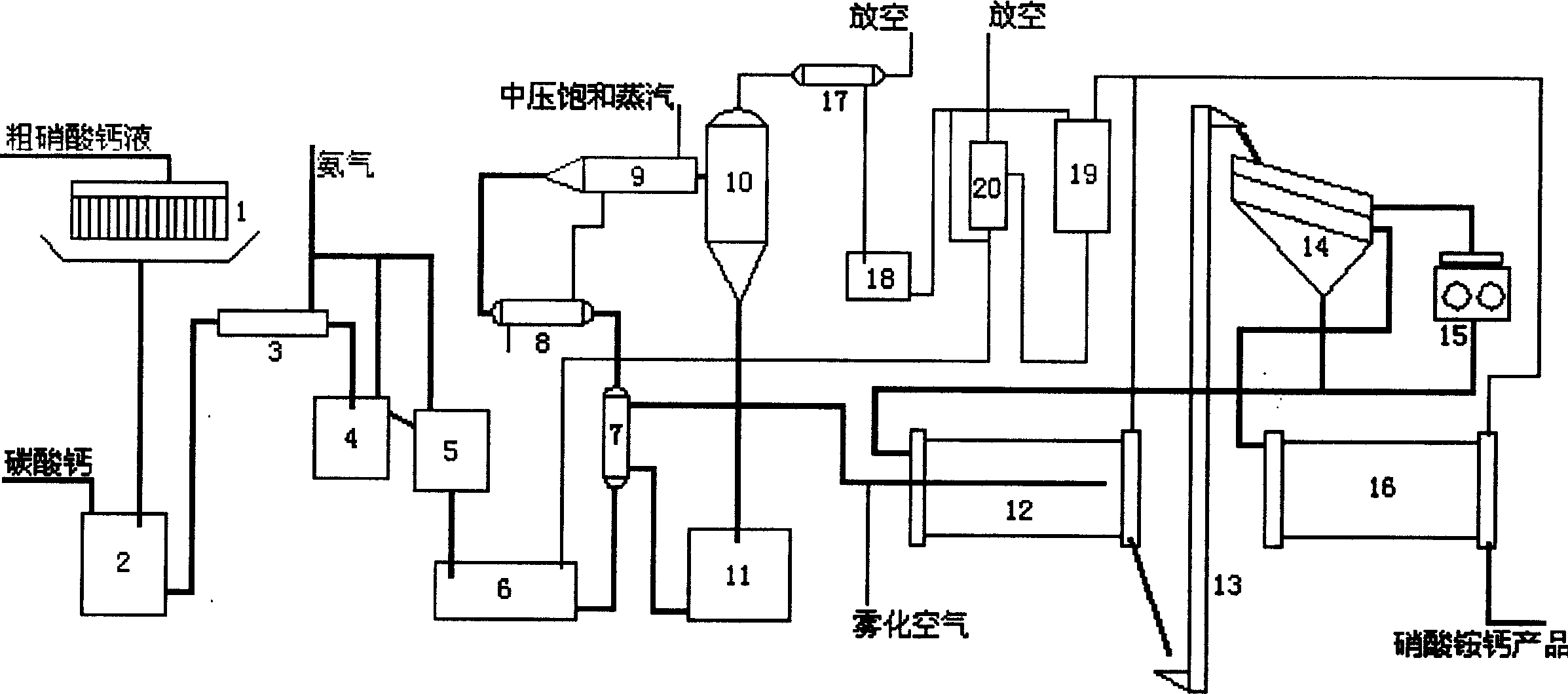

[0047] The specific process of producing calcium ammonium nitrate by utilizing nitrophosphate fertilizer by-product calcium nitrate is as follows: figure 1 Shown, come from the thick calcium nitrate storage tank of nitrophosphate fertilizer plant, the thick calcium nitrate solution that temperature is 80 ℃ is squeezed in the filter press 1 through the filter press feeding pump with the pressure of 0.2Mpa, the present invention is equipped with two The filter press operates intermittently once it is turned on and then backed up to ensure continuous filter press. Through the filtration of the filter press 1, about 1% acid-insoluble matter in the thick calcium nitrate solution is filtered out, and the dense phase after the press filtration is returned to the thick calcium nitrate storage tank, and the filtrate flows into the filtrate tank 2 by itself.

[0048] If analyze when the acid concentration in the thick calcium nitrate solution in the thick calcium nitrate storage tank su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com