Cation type water-soluble polymer dispersion

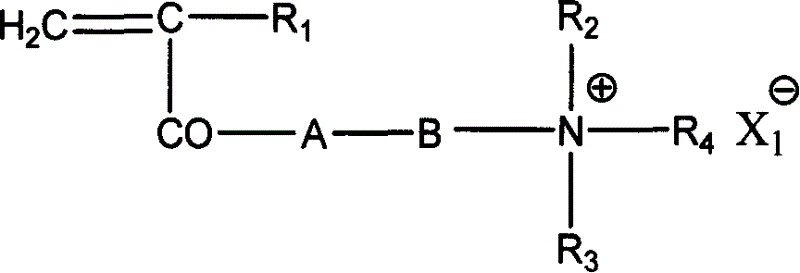

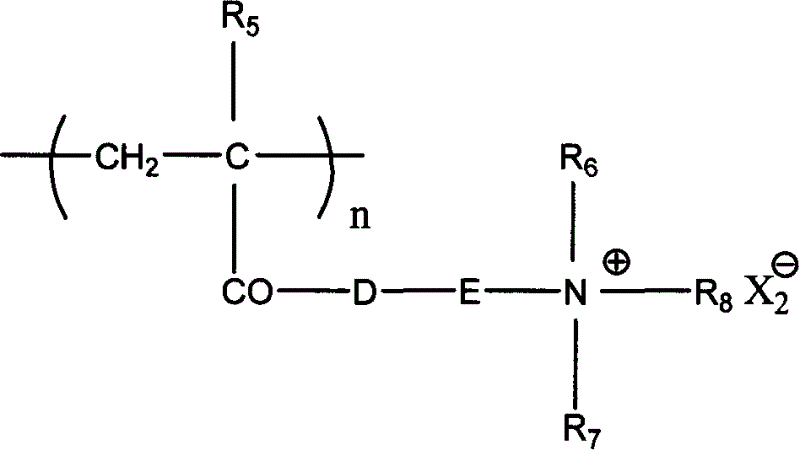

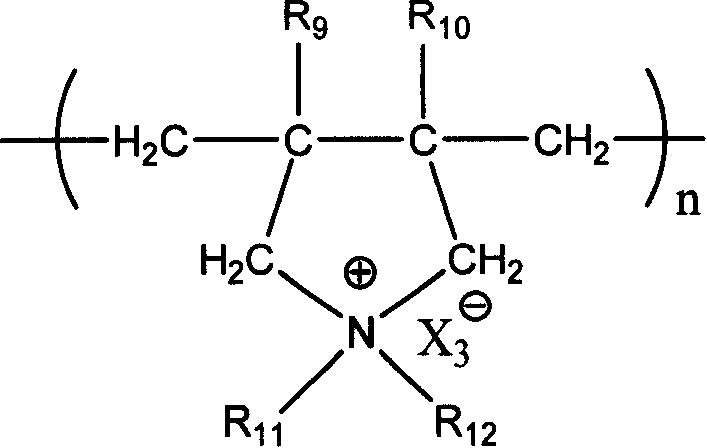

A water-soluble polymer, cationic technology, applied in the field of preparation of cationic water-soluble polymer dispersions, can solve the problems such as the inability of the dispersion polymerization reaction to proceed normally, the high viscosity of the system, and the influence on the performance of high molecular weight polymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0044] Synthesis Example 1: Preparation of Cationic Addition Polymer Dispersant.

[0045] Get 60g of acrylate trimethylamine ethyl chloride (DAC) according to the sequence number 1 of table 1 or get 60g of acrylate trimethylamine ethyl chloride (DAC) and acrylamide (AAM) according to the proportioning ratio of table 1 sequence number 2 ) or take 60g of N, N-dimethyl-N', N'-diallyl ammonium chloride (DD) according to the proportioning ratio of No. 3 in Table 1, add sulfuric acid dropwise to adjust the The pH is 3, after the temperature is raised to 42 degrees, the nitrogen gas is passed for about 30 minutes, and 3 g of 2% aqueous solution of V-50 is added to initiate the polymerization system. After 15 hours of reaction, the heating was stopped to obtain a cationic addition polymer dispersant. See No. 1, No. 2 and No. 3 in Table 1 for details. The weight-average molecular weight and cationicity were measured respectively by static light scattering and colloid titration analys...

Synthetic example 2

[0046] Synthesis Example 2: Preparation of Condensed Polymer Dispersant.

[0047] Add 90 g of 50% dimethylamine (DA) aqueous solution and 97.8 g of deionized water in a 500 ml 4-neck round bottom flask equipped with a thermometer, a nitrogen inlet, a stirrer and a continuous monomer addition tube. Within 1 hour, 101.8 g of epichlorohydrin (EPI) was added dropwise at a molar ratio of 1:1.1, and an ice-water bath was used to keep the system temperature at 50° C. during the dropwise addition. After reacting for 5 hours, the reaction was terminated to obtain a condensed polymer dispersant. The results are shown in No. 4 of Table 1.

Synthetic example 3

[0048] Synthesis Example 3: Synthesize the condensation polymer dispersant according to the method of Synthesis Example 2, the results are shown in the serial number 5-6 of Table 1.

[0049] Below is the embodiment that prepares cationic water-soluble polymer dispersion:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com