Buffering layer of ternary nitride for nitride luminescent assembly and its production

A technology of ternary nitride and light-emitting components, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of inability to effectively reduce dislocation density, reduce production efficiency, and increase difficulty, so as to simplify the heating and cooling process and time , Improve control and simplify process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

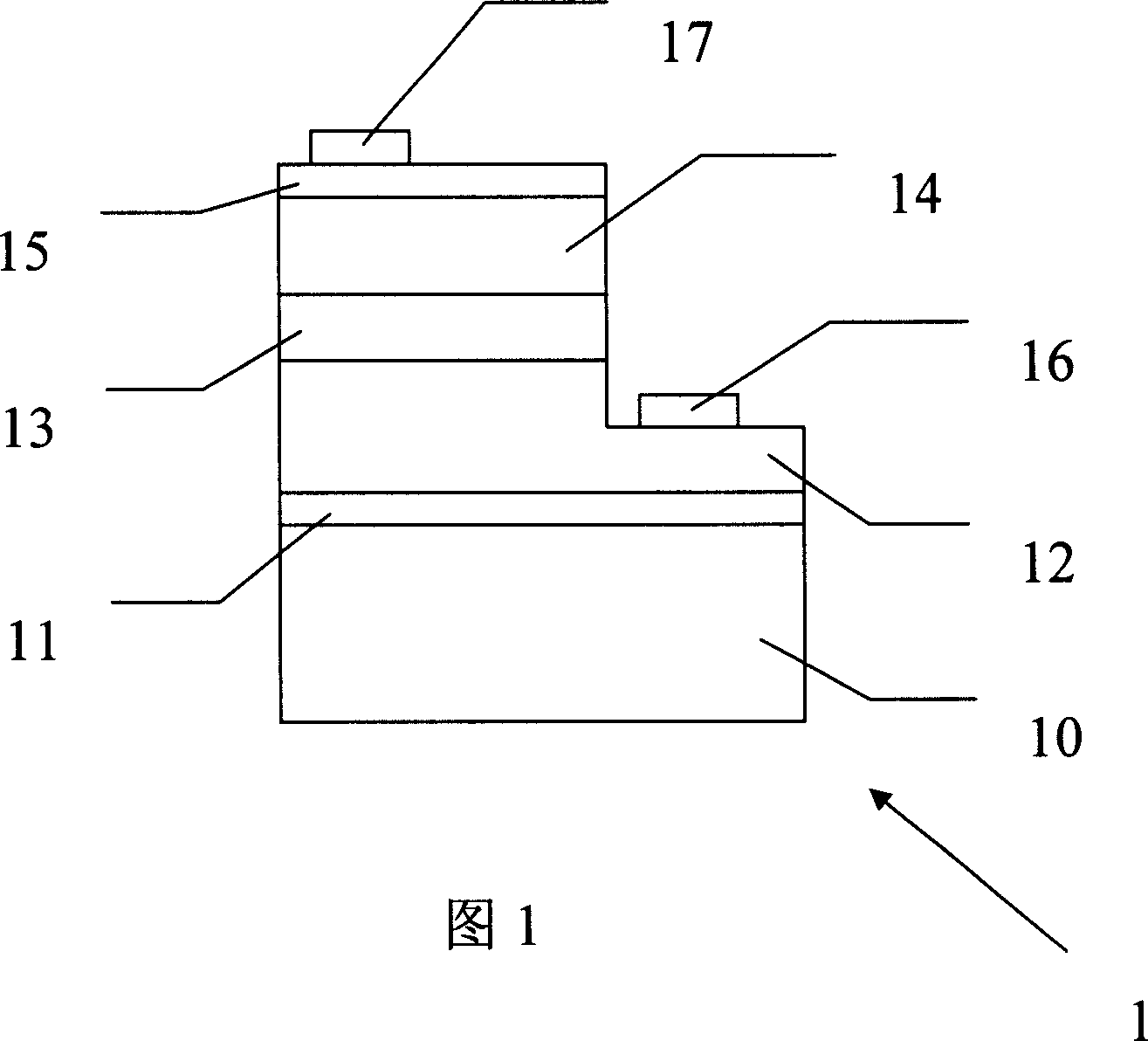

[0030] Please refer to FIG. 1, according to a preferred embodiment of the present invention, it is a nitride light-emitting component 1 with an aluminum gallium nitride (AlGaN) buffer layer, including a sapphire substrate 10; an aluminum gallium nitride buffer layer formed on the sapphire substrate 11. An N-type nitride semiconductor stack 12 formed on the aluminum gallium nitride buffer layer 11, wherein the surface of the N-type nitride semiconductor stack 12 away from the substrate 10 includes an epitaxial region 121 and an N-type electrode contact region 122; The gallium nitride / indium gallium nitride multiple quantum well light-emitting layer 13 formed on the epitaxial region 121; the P-type nitride semiconductor stack 14 formed on the nitride multiple quantum well light-emitting layer 13; formed on the P The metal transparent conductive layer 15 on the nitride semiconductor lamination layer 14; the N-type electrode 16 formed on the N-type electrode contact region 122; and...

Embodiment 2

[0033] Another preferred embodiment of the present invention is a nitride light-emitting component 2 with an aluminum gallium nitride (AlGaN) buffer layer. Its component structure is similar to that of embodiment 1, only the material and manufacturing method of the buffer layer are different. The formation steps of the aluminum gallium nitride buffer layer are as follows:

[0034] The organoaluminum reaction source TMAl is introduced at 1020°C to form an aluminum-rich transition layer; the organic gallium reaction source TMGa and the nitrogen reaction source NH are introduced at the same temperature 3 , to directly grow high-temperature gallium nitride stacks; during this period, the aluminum atoms in the aluminum-rich transition layer will diffuse upwards, and the nitrogen atoms and gallium atoms above it will also diffuse downwards to bond with the aforementioned aluminum atoms and rearrange them, thereby forming AlGaN buffer layer.

[0035] In the nitride light-emitting de...

Embodiment 3

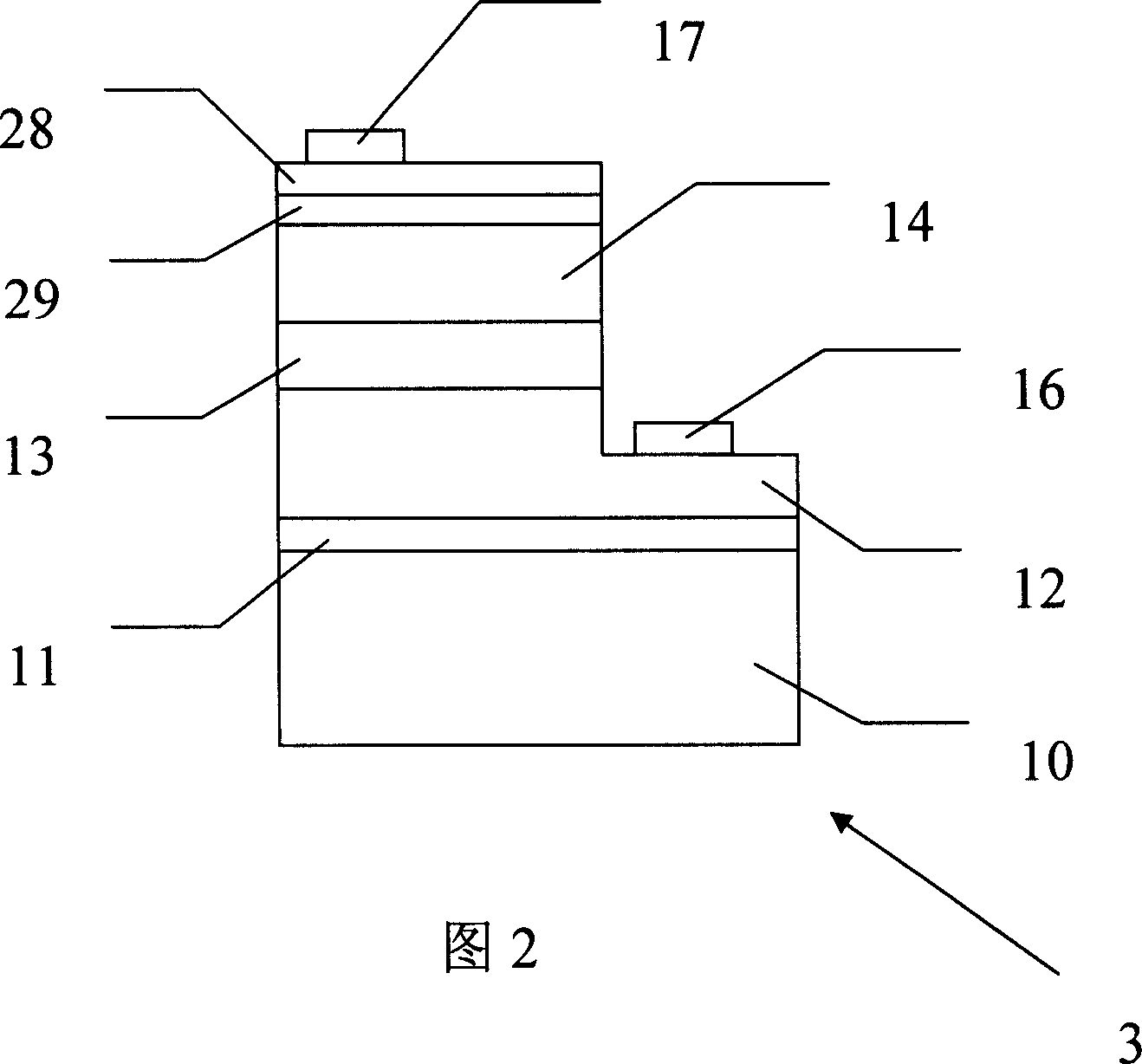

[0037] Please refer to FIG. 3 , according to another preferred embodiment of the present invention, a nitride light-emitting component 3 with an aluminum gallium nitride (AlGaN) buffer layer, and a nitride light-emitting component with an aluminum gallium nitride (AlGaN) buffer layer The difference between 1 and 2 is that the metal transparent conductive layer on the P-type nitride semiconductor layer 14 is replaced by a transparent oxide conductive layer 28, and a high concentration of N is formed between the P-type nitride semiconductor layer 14 and the transparent oxide conductive layer 28. Type reverse tunnel contact layer 29, its thickness is less than 10nm, and its carrier concentration is higher than 1×10 19 cm -3 above. Since the transparent oxidized conductive layer 28 and the P-type nitride semiconductor layer 14 are less likely to form a good Ohmic contact, the transparent oxidized conductive layer is formed through the high-concentration N-type reverse tunnel cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com