Process for biological oxidation treatment of gaseous pollutant

A technology of biological oxidation and treatment methods, applied in chemical instruments and methods, separation methods, air quality improvement, etc. The problem of high load, to achieve major market development prospects, overcome the effects of small biomass and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

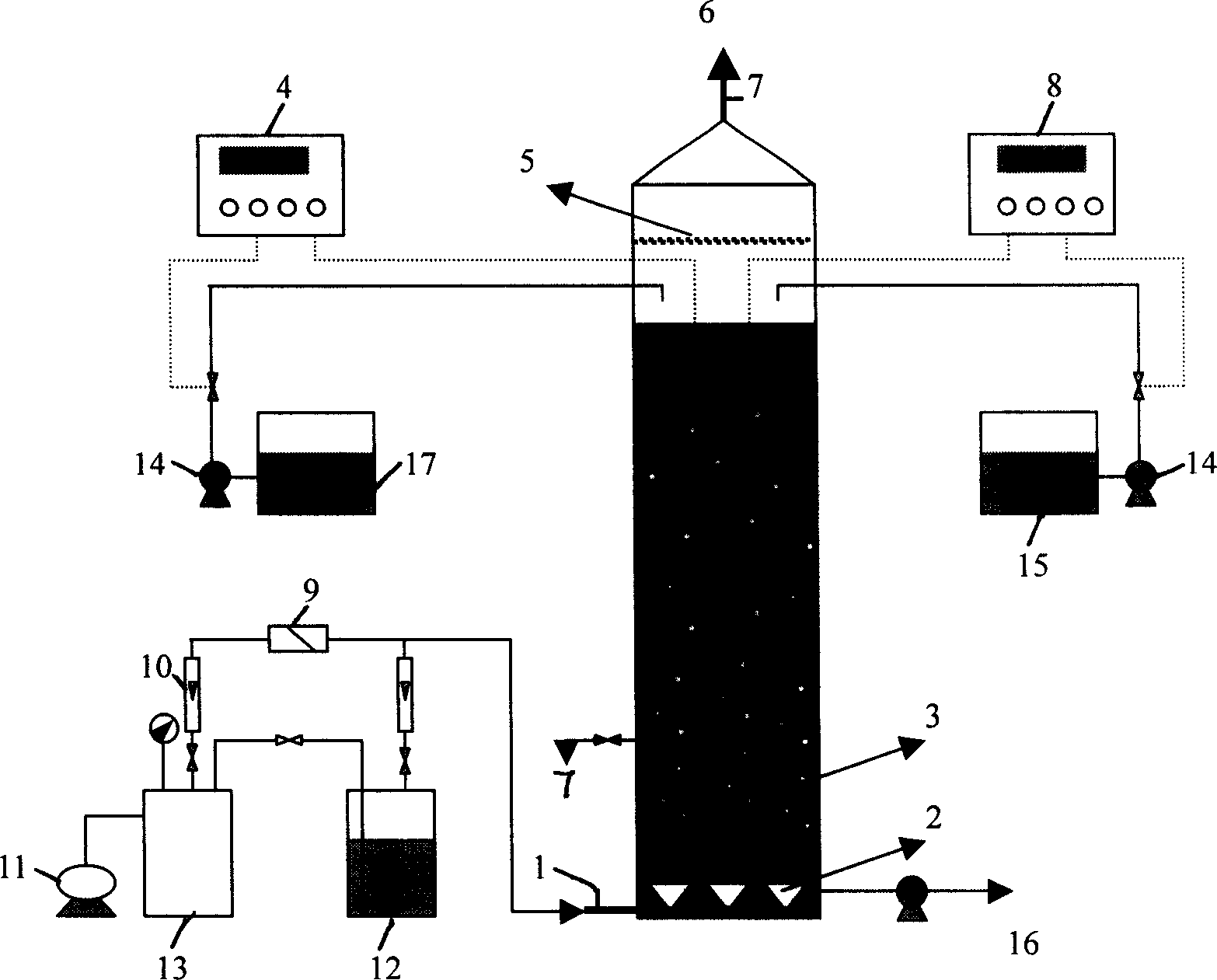

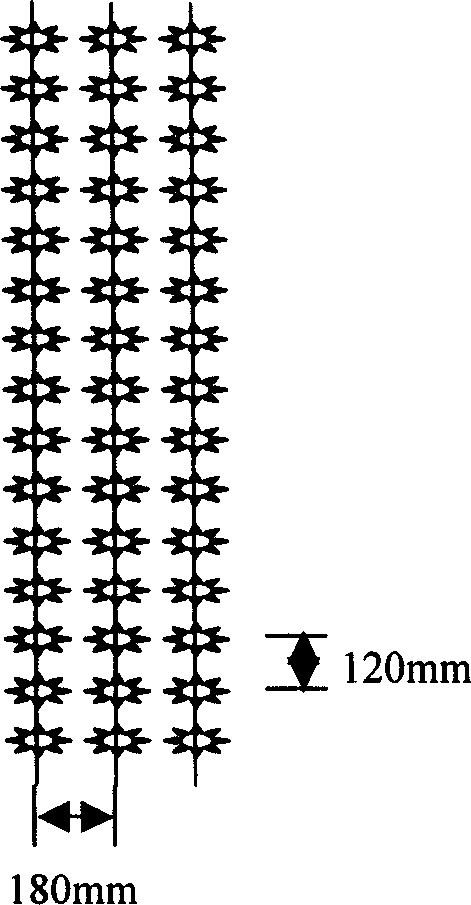

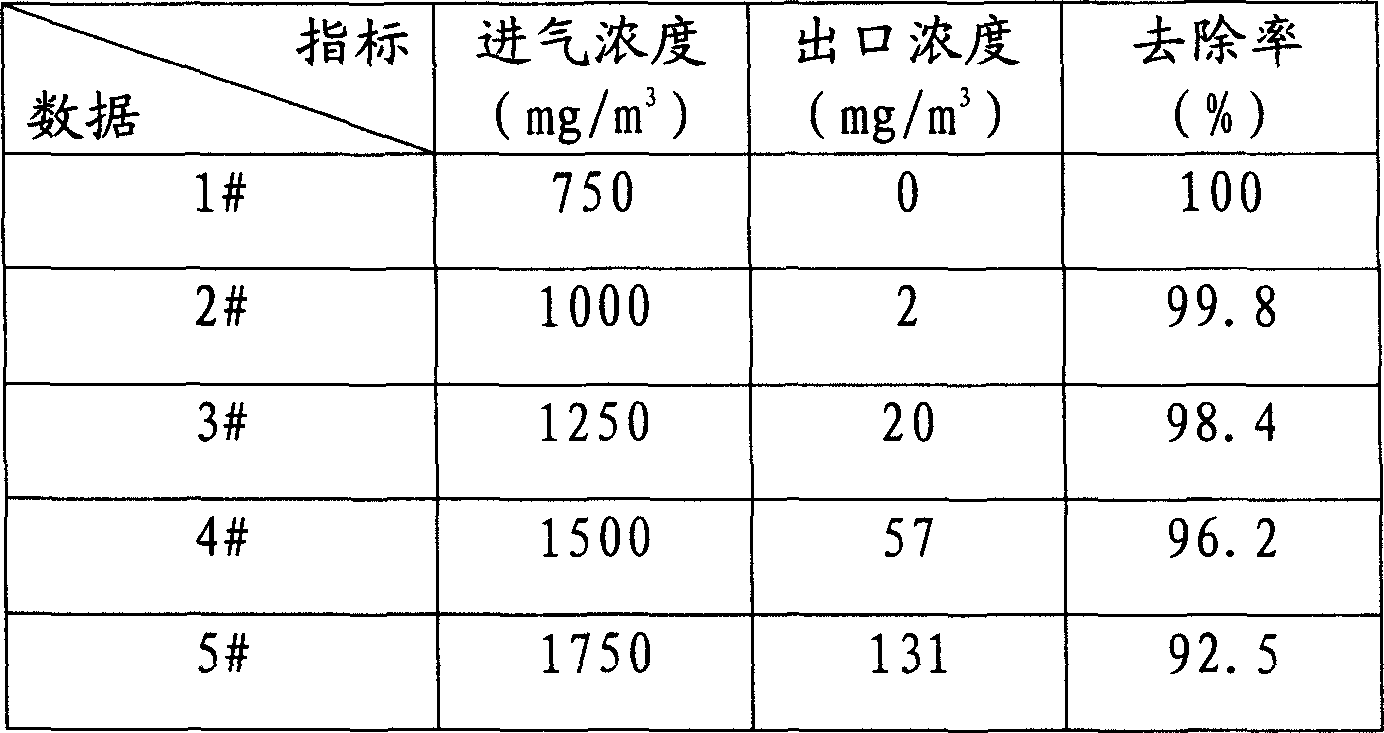

[0021] The embodiment and working principle of the present invention are: containing dichloromethane 0.75g / m 3 , 1.00g / m 3 , 1.25g / m 3 , 1.50g / m 3 , 1.75g / m 3 Waste gas biological contact oxidation tower treatment process, the tower has built-in combined biofilm packing, the nutrient solution is immersed in the entire biofilm packing, the waste gas containing methylene chloride enters from the bottom of the tower, forms tiny bubbles through the aeration diffuser, and the biofilm on the packing Fully contact with the liquid biofilm to complete the mass transfer from the gas phase to the liquid phase and then to the biofilm. Finally, under the action of biological oxidation and decomposition, the compound is oxidized and decomposed into CO 2 、H 2 O and other simple compounds to achieve the purpose of exhaust gas purification. The empty tower residence time (EBRT) is 15s, the pH value of the liquid phase is 6.0-7.0, and the temperature is 25-35°C. The waste gas treatment res...

Embodiment 2

[0026] Embodiment of the present invention and principle of work are: other conditions are the same as embodiment 1, empty tower residence time (EBRT) is 10s, liquid phase pH value 6.0~7.0, temperature 25~30 ℃, treatment result sees table 2.

[0027] Table 2 Dichloromethane waste gas treatment results

[0028]

[0029] The results in Table 2 show that the biological contact oxidation waste gas treatment process of the present invention can effectively treat waste gas containing methylene chloride, and the removal rates of methylene chloride are 100%, 97.7%, 94.5%, 90.3%, and 83.1%, respectively.

Embodiment 3

[0031] Embodiment of the present invention and working principle are: other conditions are the same as embodiment 1, empty tower residence time (EBRT) is 20s, liquid phase pH value 6.0-7.0, temperature 25-35 ℃, treatment result sees table 3.

[0032] Table 3 Dichloromethane waste gas treatment results

[0033]

[0034] The results in Table 3 show that the biological contact oxidation waste gas treatment process of the present invention can effectively treat waste gas containing methylene chloride, and the removal rates of methylene chloride are 100%, 100%, 98.8%, 97.1%, and 94.3%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com