Thermoplastic polyimide resin film, multilayer body and method for manufacturing printed wiring board composed of same

A technology of polyimide resin and resin film, which is applied in printed circuit manufacturing, printed circuit, multilayer circuit manufacturing, etc., and can solve complicated problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

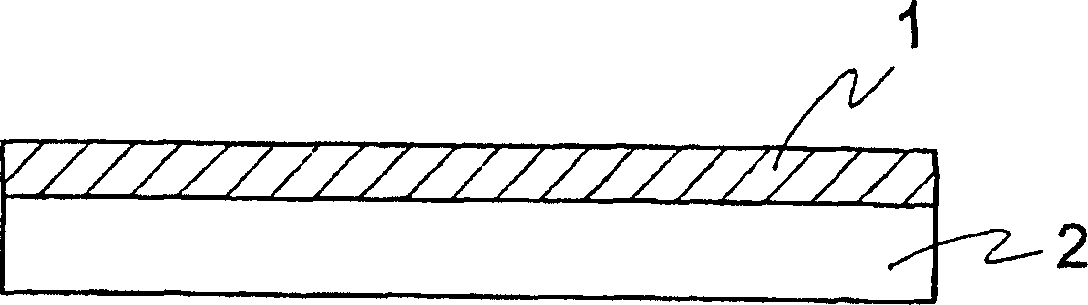

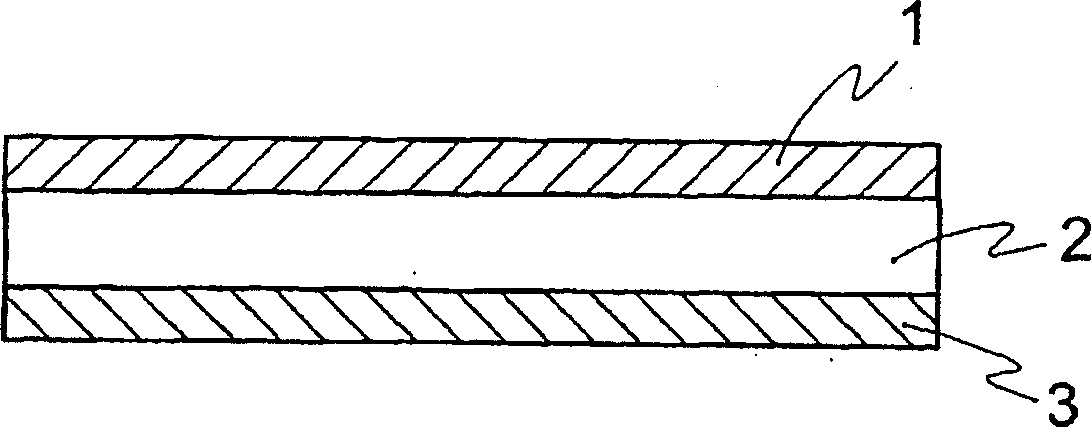

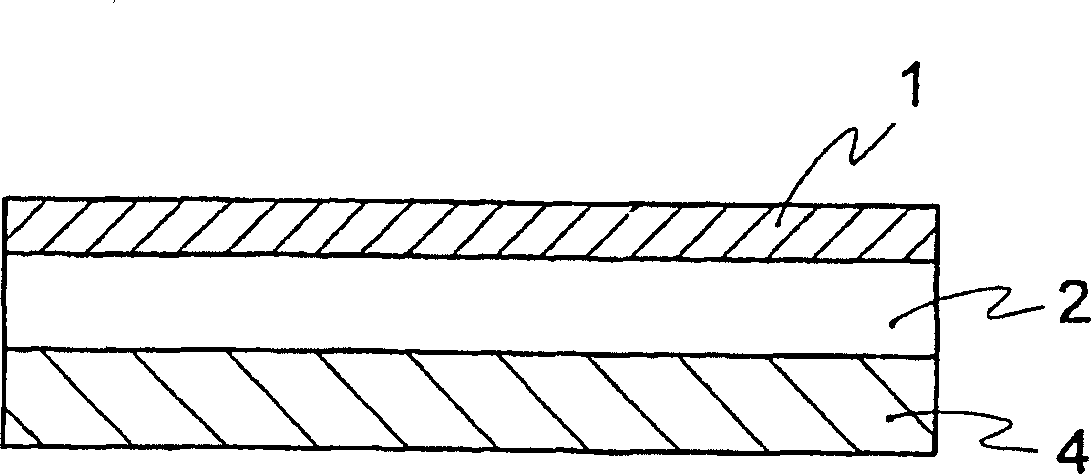

[0277] Coating the polyamic acid solution prepared by manufacturing method X, Y, Z on one side of non-thermoplastic polyimide film A~C with a thickness of 25 μm prepared by polyimide film preparation method A, B, C to make a laminate layers. The thickness of the thermoplastic polyimide layer is 3 μm. The copper foil and the thermoplastic polyimide layer were superimposed, and hot roll lamination was carried out under the conditions of a temperature of 340°C, a line pressure of 20kgf / cm, and a line speed of 1.5m / min. As the copper foil, 18 μm (Rz=1.5 μm) rolled copper foil BHY-22B-T manufactured by Japannagi was used. Next, the laminated copper foil was completely removed with a hydrochloric acid / ferric chloride-based etchant to obtain a laminate in the present invention having a surface-treated thermoplastic polyimide resin film. Determination of surface roughness after surface treatment.

[0278] Next, electroless copper plating and electrolytic copper plating were perform...

Embodiment 10~26

[0284] Experiments were conducted to confirm the effects of various surface treatments. A laminate was prepared by coating one side of a non-thermoplastic polyimide film having a thickness of 25 μm prepared by polyimide film preparation method B with the polyamic acid solution prepared by preparation method Y. The thickness of the thermoplastic polyimide layer is 1, 3, 5 μm.

[0285] (1) Surface treatment with electrodeposited copper foil Electrodeposited copper foil 3EC-VLP foil (thickness 18 μm, Rz=4.6 μm) manufactured by Mitsui Kinzoku Co., Ltd. was laminated in the same manner as in Examples 1 to 9.

[0286] (2) The surface treatment with permanganate was carried out using the permanganate decontamination system manufactured by Artec Co., Ltd. shown in the table below.

[0287]

[0288] process

Treatment liquid composition

processing conditions

swelling

Salinger Krigant (Suering Seki Yurigant) P(*)

...

Embodiment 27-38

[0300] On both sides of the non-thermoplastic polyimide film C with a thickness of 7.5 μm, 12.5 μm, 25 μm, and 50 μm prepared by the preparation method C of the polyimide film, the polyamic acid solution prepared by the preparation method Y is coated with this method. Laminates formed of thermoplastic polyimide layers of different thicknesses were fabricated. The surface treatment using the copper foil described in Examples 1-9 was performed on this thermoplastic polyimide layer, and the thermal expansion coefficient was measured. Thereafter, electroless plating and electroplating were performed in the same manner as in Examples 1 to 9 to form a copper layer with a thickness of 18 μm, and the adhesive strength at room temperature and the adhesive strength after the pressure cooking test were measured. The results are listed in Table 5. In addition, regarding the thermal expansion coefficient, the thermal expansion coefficient of the non-thermoplastic film C was 12ppm / °C in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com