Method for measuring size distribution of grains in Nano level through method of capillary electrophoresis

A capillary electrophoresis, nano-scale technology, applied in the direction of particle and sedimentation analysis, particle size analysis, measuring devices, etc., can solve the problems of difficult quantitative and statistical analysis, high laser source price, high instrument price, etc., to achieve simple structure and easy operation line, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

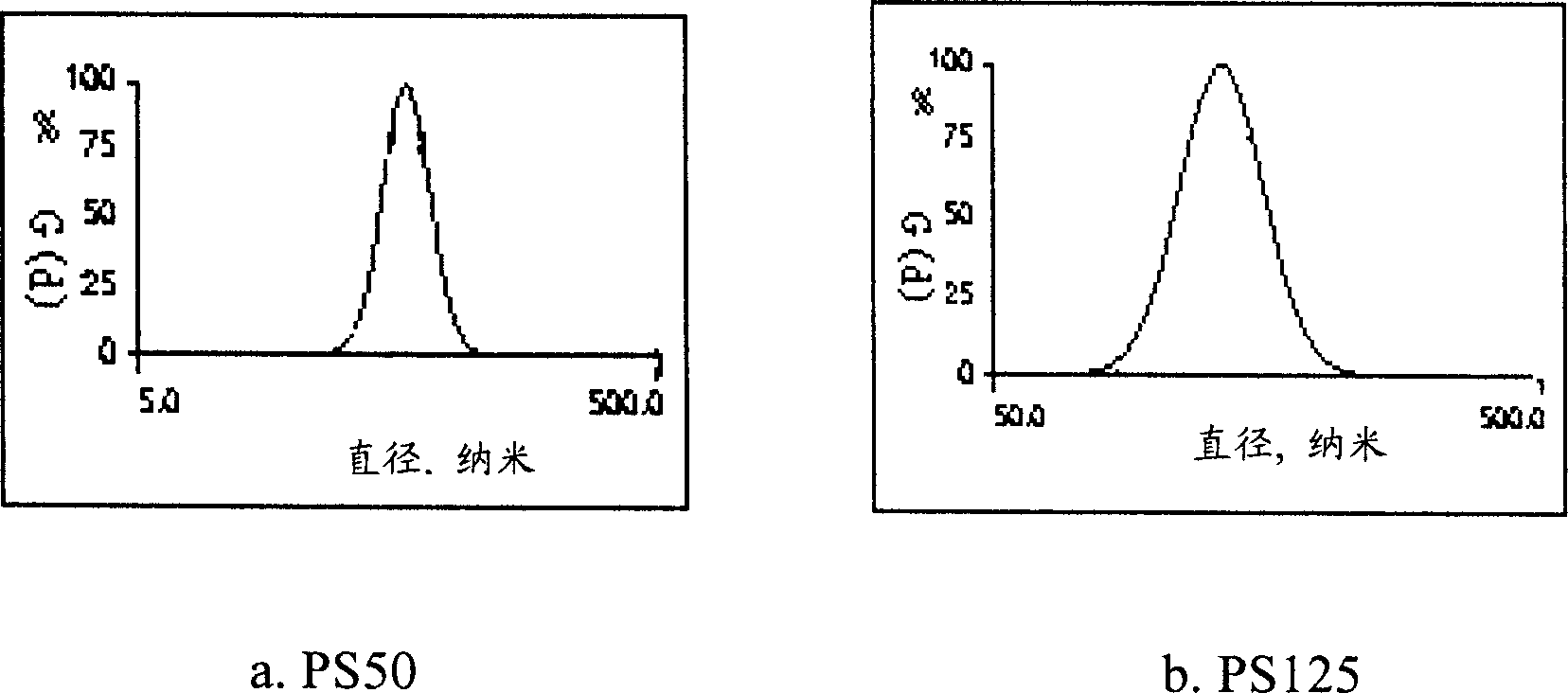

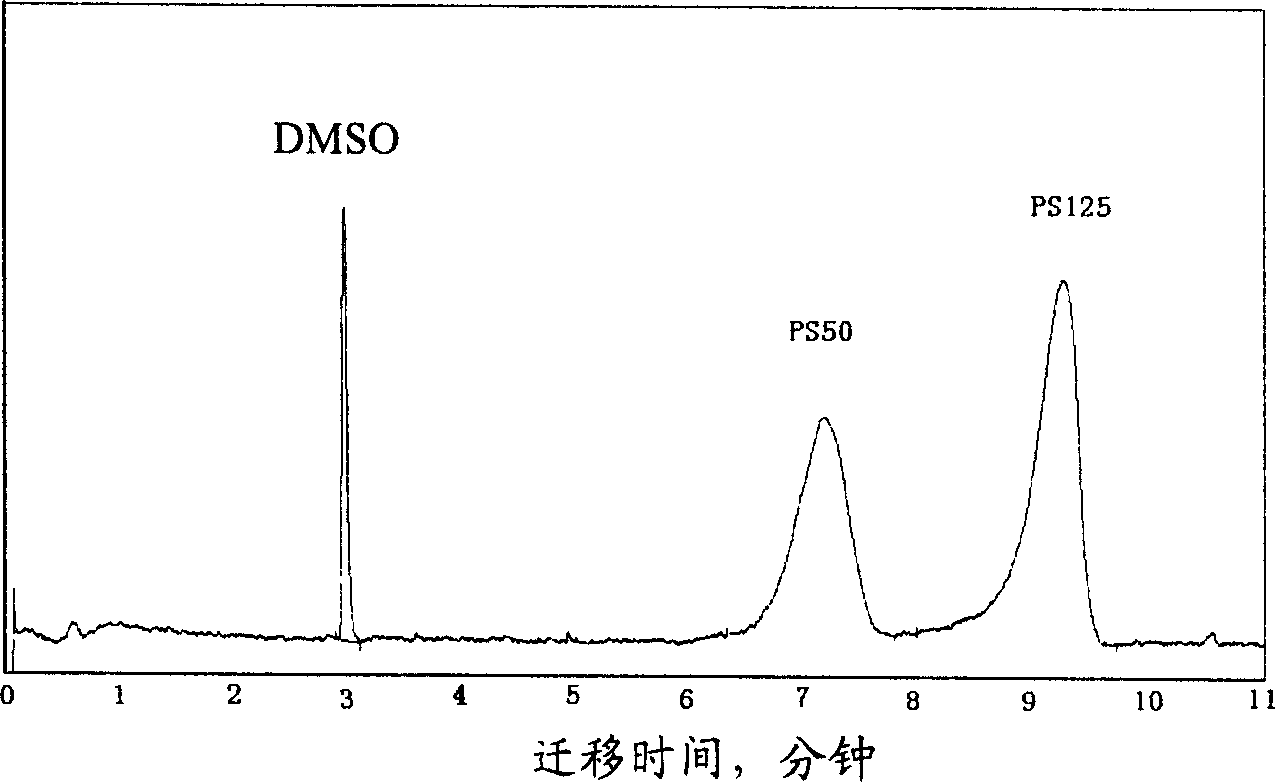

[0032] The particle size distribution and average particle size of polystyrene (PS) latex particles are measured by the method of the present invention.

[0033] The PS standard sample used in the example is PS20, PS50, PS90 and PS125 (U.S., Duke Scientific Corporation), and average particle size is respectively (21 ± 1.5) nm; (50 ± 2.0) nm; (92 ± 3.7) nm; (125 ±4) nm.

[0034] 1. Establish particle size-adjusted migration time correlation equation

[0035] (1) Measure the particle size distribution of the standard sample with a laser particle size analyzer

[0036] Prepare Na with a concentration of 5mmol / L 2 CO 3 and 1.25mmol / L NaHCO 3 mixed solution as a buffer solution. The buffer solution was used to prepare a suspension of PS50 and PS125 with a concentration of 0.01% by volume. Use an ultrasonic cleaner to ultrasonically disperse for 5 minutes, and then use a laser particle size analyzer to measure the particle size distribution of the dispersed particles. The part...

example 2

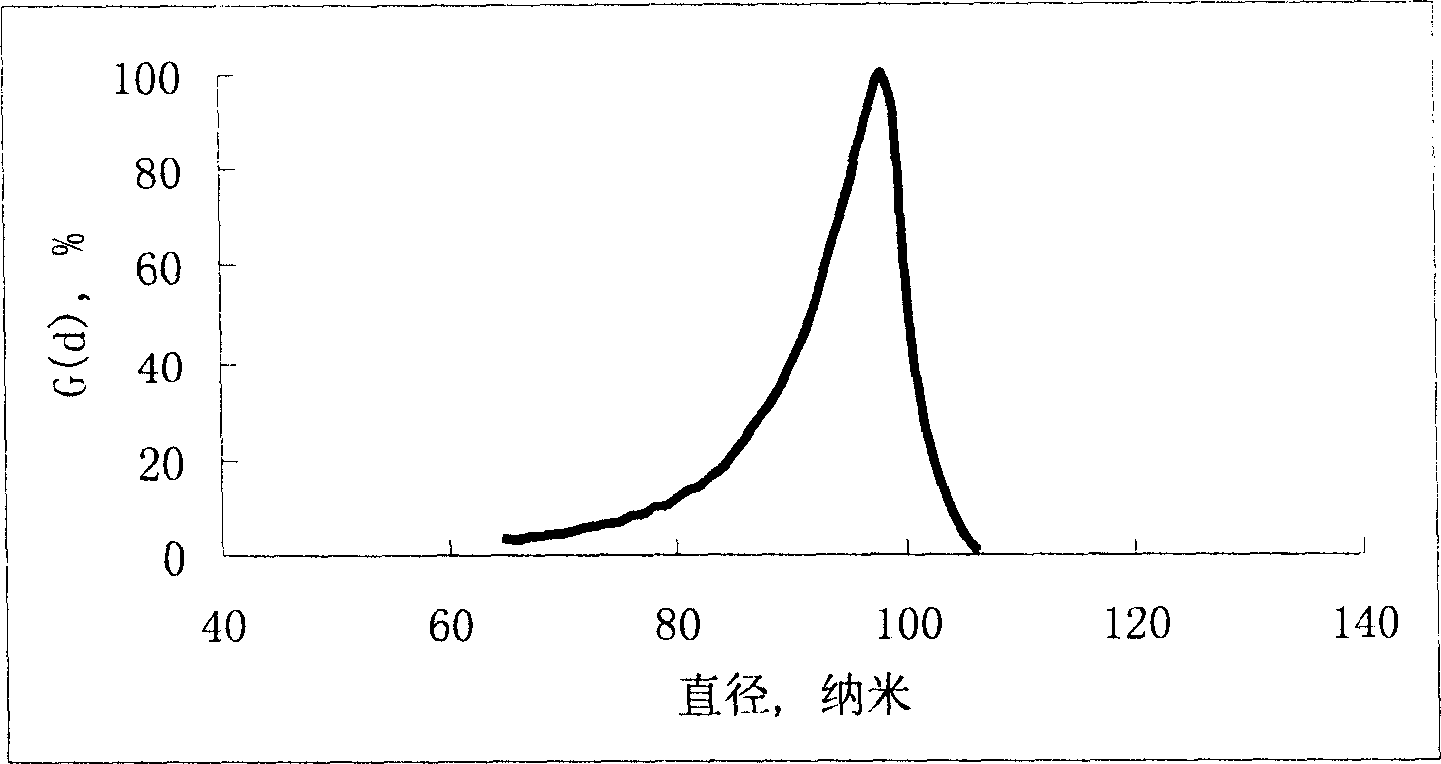

[0052] Determination of particle size distribution and average particle size of ultrafine β molecular sieve.

[0053] 1. Establish particle size-adjusted migration time correlation equation

[0054] Prepare the β molecular sieve with buffer solution to a suspension with a concentration of 5 g / L, and ultrasonically disperse it for 5 minutes to prepare a standard sample suspension.

[0055] The standard sample suspension was measured by a laser particle size analyzer, and the particle size distribution results of the standard sample are shown in Table 3.

[0056] The β molecular sieve standard sample suspension was subjected to electrophoresis separation and detection by gravity sampling method. The inner diameter of the capillary used for the separation was 100 μm. Figure 4 .

[0057] The G(d) data corresponding to the different particle sizes in Table 3 and the peak height value of the cumulative distribution of the spectral peak area corresponding to this value in the elec...

example 3

[0069] Prepare the suspension of 7 different β molecular sieve samples by 3 step methods in example 2, then test with capillary electrophoresis (CZE), the average particle diameter (d) of each sample test pcs ) and the results of the laser particle size analyzer (PCS method) are listed in Table 7. Table 7 shows that the result of the method test of the present invention is basically consistent with the PCS method.

[0070] PS50

PS125

Particle diameter,

nm

G(d), %

C(d), %

Particle diameter,

nm

G(d), %

C(d), %

33.9

36.9

39.1

40.9

42.5

44.0

45.4

46.8

48.2

49.6

51.0

52.3

53.8

55.4

57.0

58.2

60.4

62.5

65

26

44

58

70

80

87

93

97

99

100

99

97

93

87

80

70

58

44

26

5

10

15

20

25

30

35

40

45

50

55

60

65

70

7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com