Method and apparatus for crystallization

一种结晶、晶体的技术,应用在结晶分离、溶液结晶、分离方法等方向,能够解决过滤操作耗费时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

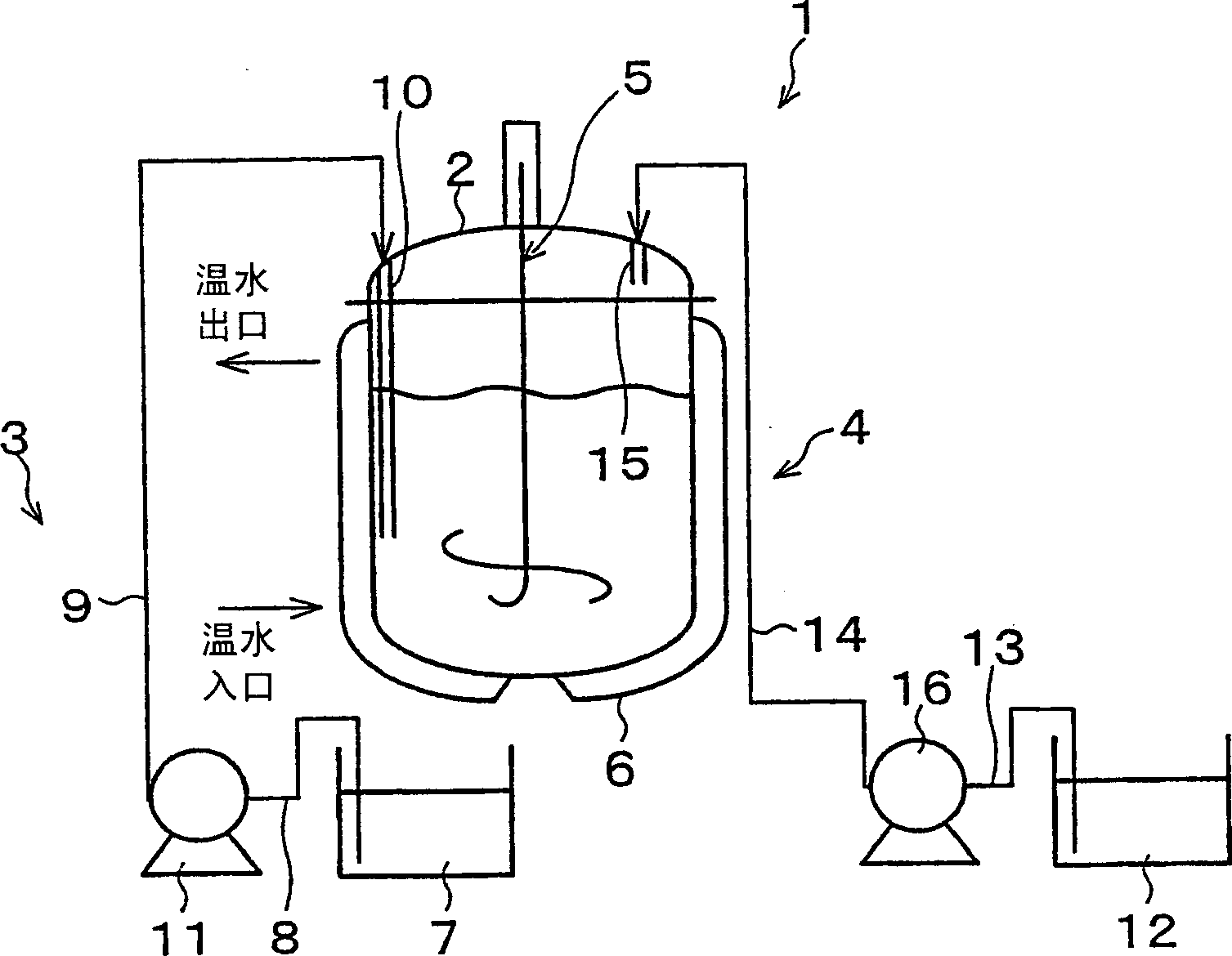

Embodiment 1

[0162] Add 12.02 grams of salicylic acid, 15.17 grams of 8 mol / liter (20°C) sodium hydroxide aqueous solution and 499.87 grams of water, salicylic acid is completely dissolved and made raw material organic acid salt solution (reaction stock solution).

[0163] Next, set the stirring speed of the above-mentioned three swept wings to 370rpm, and use a quantitative pump at an internal temperature of 30°C to add 19.14 grams of 6 mol / liter dropwise to the surface of the solution in the above-mentioned detachable flask in 29 minutes (20°C) hydrochloric acid. At 7 minutes after the start of hydrochloric acid dropwise addition, sharp precipitation of crystals was observed with the naked eye.

[0164] Next, after adding 11.02 g of 8 mol / liter sodium hydroxide aqueous solution (20° C.) to the surface of the solution in the above-mentioned detachable flask over 8 minutes, the solution surface in the above-mentioned detachable flask was dripped with a quantitative pump for 20 minutes. A...

Embodiment 2

[0171] In a 500 ml removable flask (reaction vessel) equipped with three swept wings (stirrer) with a radius of 23 mm, add 14.62 g of adipic acid, 17.53 g of 8 mol / L (20° C.) sodium hydroxide solution and 199.01 grams of water made the raw material organic acid salt solution (reaction stock solution) after adipic acid was completely dissolved.

[0172] Next, set the stirring speed of the above-mentioned three swept wings at 171rpm, and use a dropping funnel (dropper) at an internal temperature of 30°C to drop 40.26 grams of 6 to the lower part of the above-mentioned removable flask in 40 minutes. mol / L (20°C) hydrochloric acid.

[0173] At the 16th minute after the addition of hydrochloric acid, dropwise add 15.95 g of 8 mol / L (20° C.) sodium hydroxide using a dropping funnel to the liquid level of the reaction solution in the above-mentioned detachable flask simultaneously with the addition of the above-mentioned acid. The aqueous solution was used for 24 minutes for the dro...

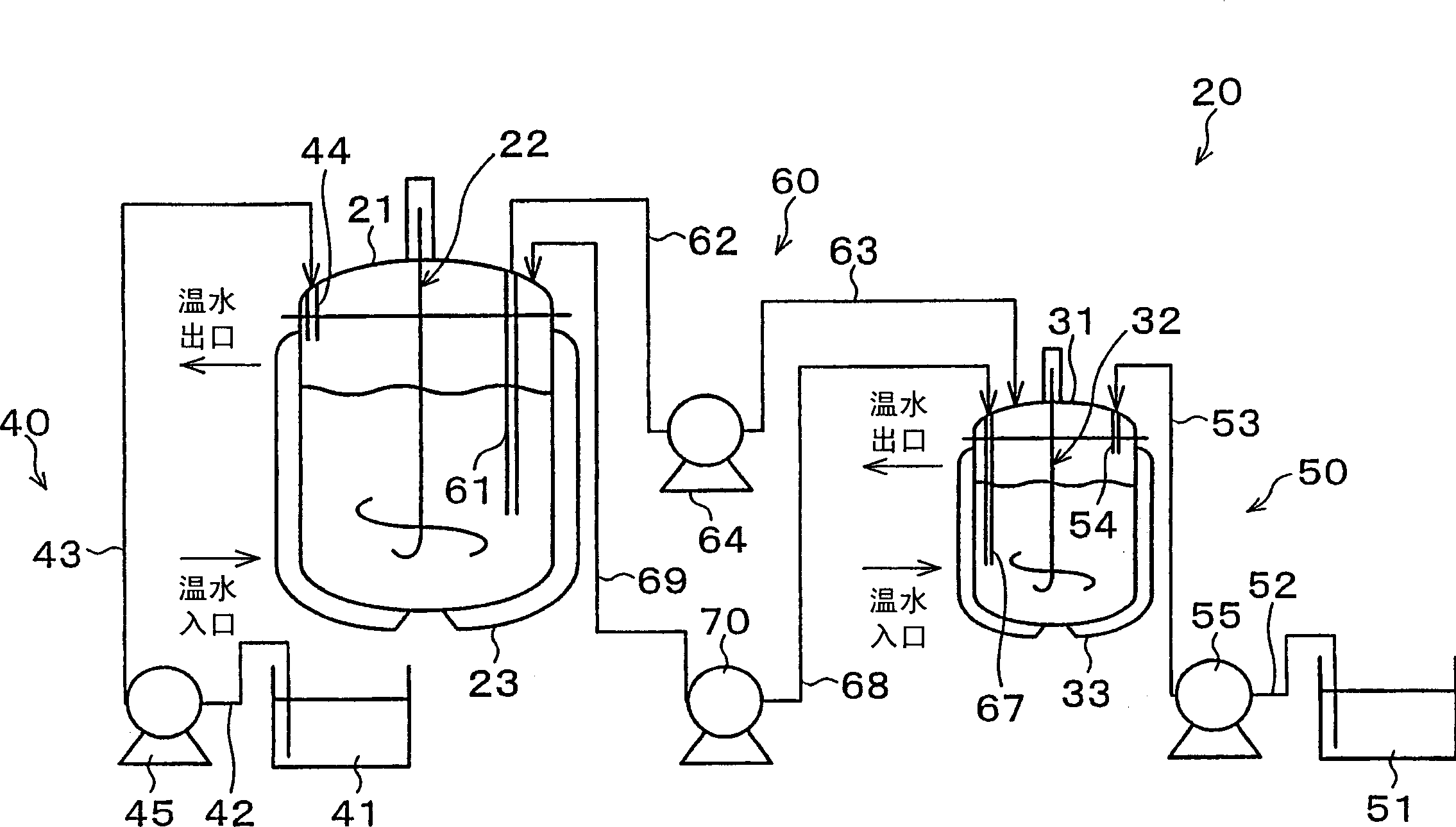

Embodiment 3

[0182] In a 1000 ml removable flask (first reaction vessel) equipped with three swept wings (stirrer) with a radius of 30 mm, add 50.13 g of biotin, 35.88 g of 8 mol / L (20°C) sodium hydroxide Aqueous solution and 600.1 gram of water, after making biotin dissolve completely, serve as raw material organic acid salt solution (reaction stock solution). The stirring revolutions of the above three swept wings were set at 300 rpm. And in the 500 milliliters of detachable flasks (the second reaction vessel) that are equipped with the swept wing (stirrer) of three radiuses 23 millimeters, add 100.22 grams of water, the stirring revolution number of above-mentioned three swept wings is set at 350rpm. An immersion tube was installed in the first reaction vessel, and the contents (reaction liquid) in the first reaction vessel were pumped at a rate of 32.8 ml / min onto the liquid surface of the contents in the second reaction vessel. Simultaneously above-mentioned second reaction vessel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com