Deep cleaning treatment process for city effluent

A technology of deep purification and treatment process, applied in water/sewage multi-stage treatment, heating water/sewage treatment, adsorption water/sewage treatment, etc. problems, to achieve the effect of simple process method and equipment, strong adaptability to terrain environment and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

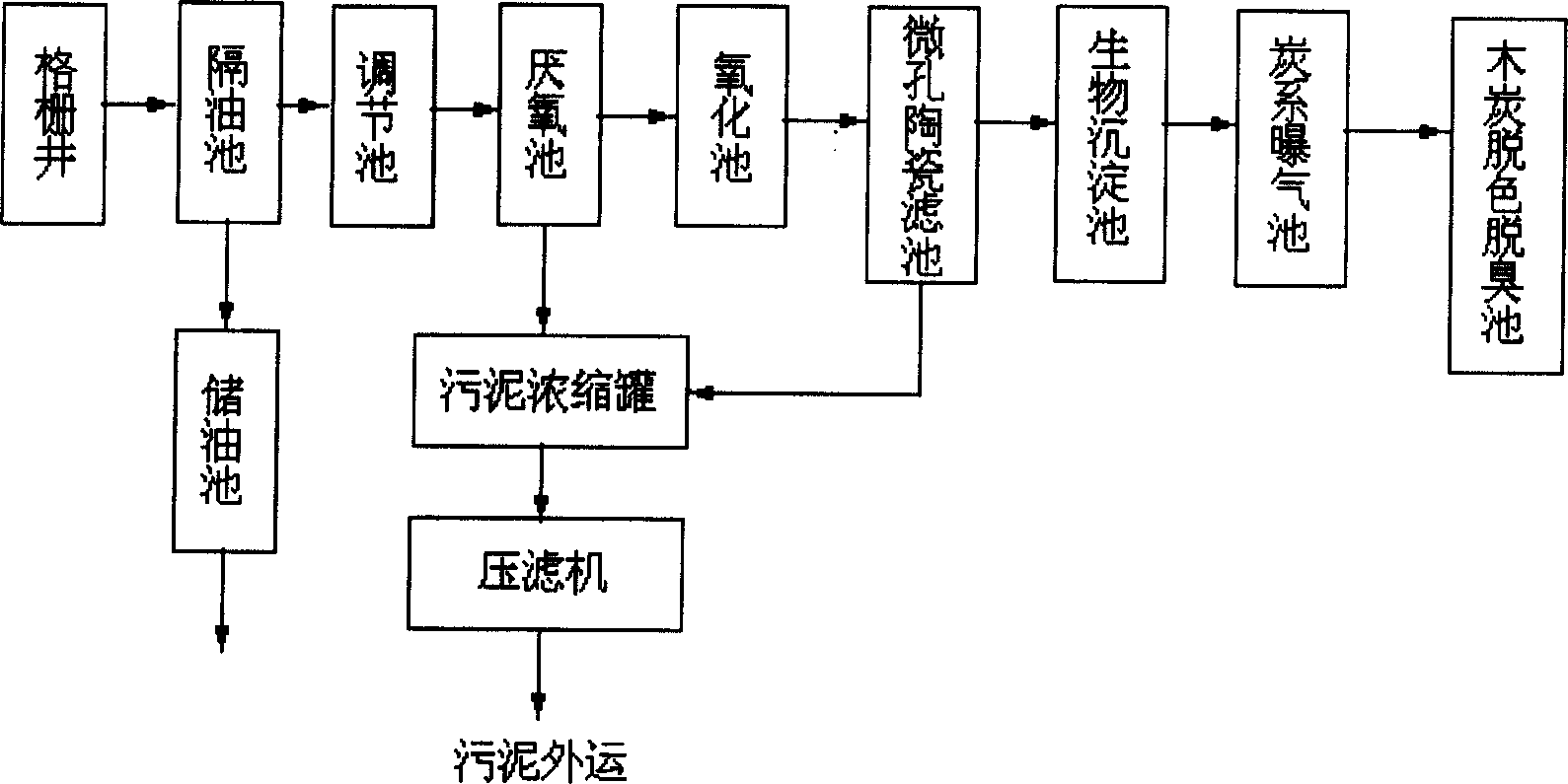

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

[0021] 1. Grill well

[0022] The sewage is concentrated by the domestic sewage drainage pipe network in the community. The sewage contains a large number of suspended and floating solids with large particles, which are cut off by the grid and removed in time. A sewage pump is placed in the grid well to extract the sewage filtered by the grid to Grease trap. The grid hole size is 10×10 mm to 30×30 mm.

[0023] The setting of the grid well is to remove the large volume of various solid substances in the sewage and reduce the burden of the next process; the second is to ensure the normal operation of the sewage pump without blocking the pump port; the third is to use the sewage pump to pump the sewage It is lifted to the grease trap with the highest level (terrain) in this treatment process, so that the sewage can complete the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com