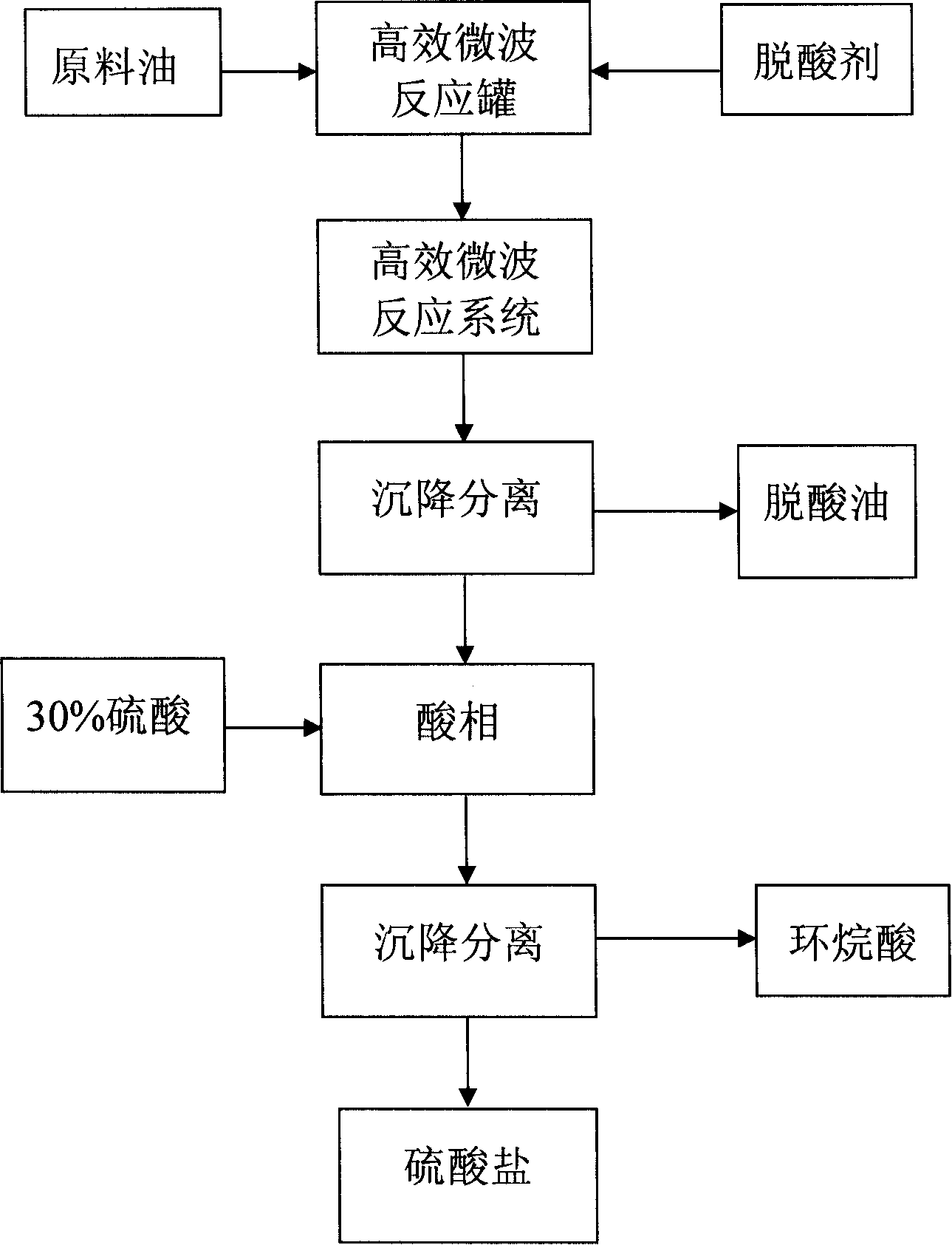

Technological process of eliminating naphthenic acid from diesel oil

A naphthenic acid and deacidification technology, applied in the field of oil refining, can solve the problems of high operating costs, consumption of hydrogen, affecting the quality and yield of oil products, etc., to improve quality and recovery rate, improve work efficiency, and reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] With reference to accompanying drawing 1, process of the present invention is further described in conjunction with embodiment.

[0014] (1) Deacidification experiment of distillate oil in the second line of Liaohe Changzhou

[0015] The raw material oil is Liaohe ordinary second-line distillate oil, and its acid value is 170.4mgKOH / 100mL. Deacidification agent is 5% sodium hydroxide solution. Add distillate oil and deacidification agent to the MD-21 high-efficiency microwave reaction tank. The volume ratio of deacidification agent to raw oil is 1:4, and put it into the SH9402 high-efficiency microwave reaction system. After 5 min of constant pressure irradiation under the condition of MPa, stop the reaction. After the reaction tank is cooled to room temperature, transfer the irradiated raw material oil into a spherical separatory funnel, let it stand for 25 minutes, and separate the upper and lower layers. The upper layer is the deacidified oil obtained after deacidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com