Electrophotographic photoreceptor and charge-transporting material for electrophotographic photoreceptor

A technology of electrophotography and charge transport, which is applied to the electrical recording process using charge patterns, the equipment and optics of the electric recording process using charge patterns, and can solve the problems of low sensitivity, poor flexibility, and inability to maintain sufficient surface potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

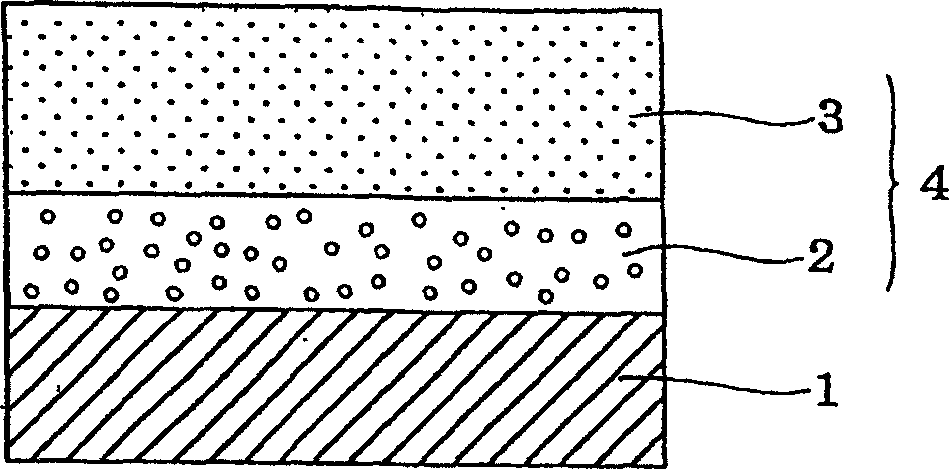

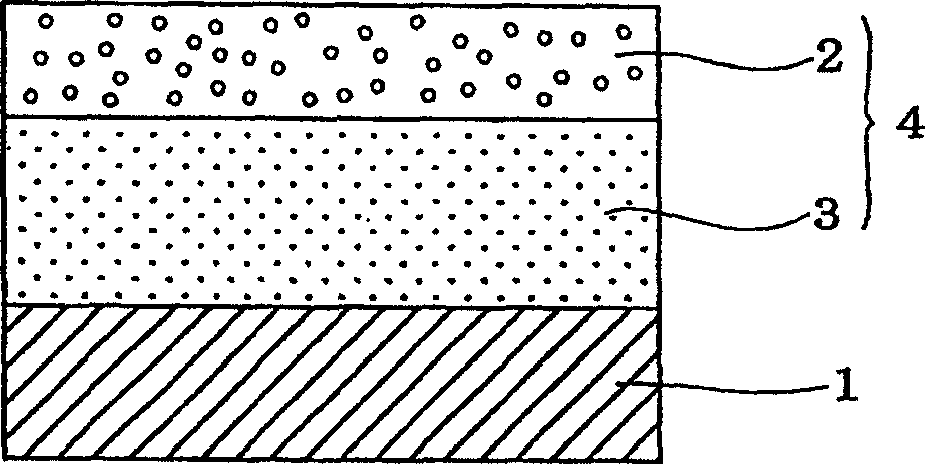

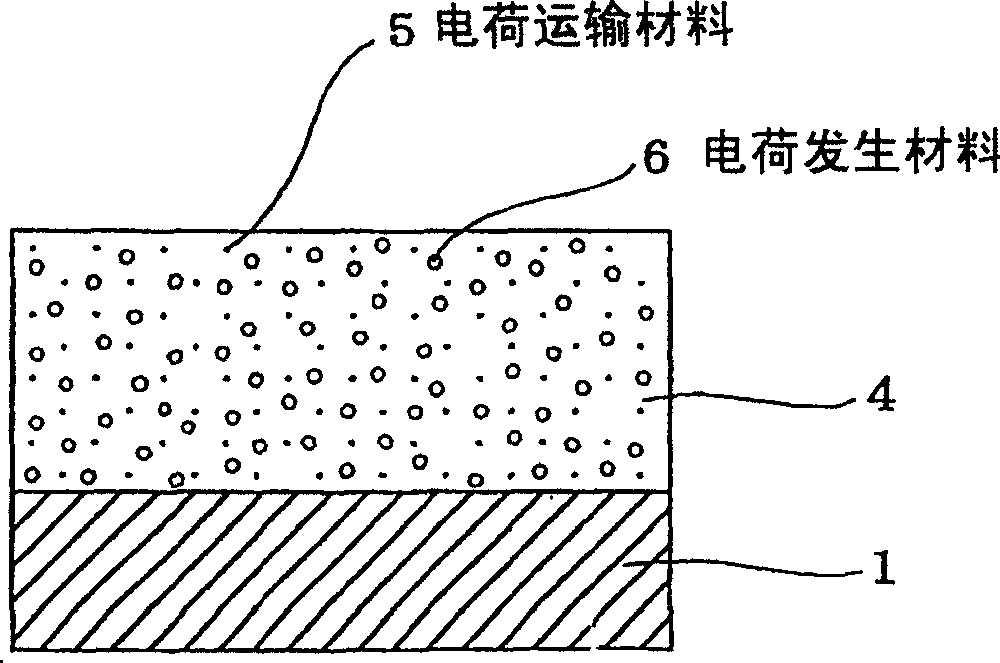

[0177] 1 part by weight of α-titanyl phthalocyanine (oxytitanyl phthalocyanine) [SANYO COLORWORKS, LTD., α-TiOPc] was added to 1 part by weight of butyral resin [poly(vinyl butyral) BL-1, manufactured by Sekisui Chemical Co., Ltd. manufactured, hereinafter the same] was dissolved in a binder polymer solution prepared in 30 parts by weight of tetrahydrofuran, and dispersed together with glass beads in a vibration attritor for 5 hours. This dispersion was applied on a sheet formed by vacuum-depositing aluminum on a polyethylene terephthalate (hereinafter abbreviated as "PET") film using a wire rod, followed by drying at 100° C. for 2 hours, thereby A charge generation layer having a thickness of about 2 μm was formed.

[0178] Subsequently, 1 part by weight of Compound 1-3 obtained in Synthesis Example 3 and 1 part by weight of polycarbonate resin, Panlite TS-2020 [manufactured by TEIJIN CHEMICALS LTD.; the same hereinafter] were mixed, and dissolved In 8 parts by weight of 1,2...

Embodiment 2

[0180] The electrophotographic photoreceptor B of the present invention was prepared in the same manner as in Example 1 except that Compound 1-9 was used instead of Compound 1-3.

Embodiment 3

[0196] 1 part by weight of β-titanium phthalocyanine [SANYO COLOR WORKS, LTD., β-TiOPc] was added to 1 part by weight of butyral resin [poly(vinyl butyral) BL-1] dissolved in 30 parts by weight of tetrahydrofuran in the binder polymer solution prepared in the medium and dispersed with glass beads in a vibrating attritor for 5 hours. The dispersion was applied on a sheet comprising a PET film with vacuum-deposited aluminum thereon using a wire rod, followed by drying at 100° C. for 2 hours, thereby forming a charge generation layer having a thickness of about 2 μm.

[0197] Subsequently, 1 part by weight of Compound 1-3 obtained in Synthesis Example 3 was mixed with 1 part by weight of polycarbonate resin, Panlite TS-2020, and dissolved in 8 parts by weight of 1,2-dichloroethylene in alkane. The solution was applied on the previously formed charge generating layer using a doctor blade, and dried at 80° C. for 3 hours to form a charge transporting layer having a thickness of ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com