Fat emulsion of biobalide B and preparation method

A fat emulsion and ginkgolide technology, applied in the field of fat emulsion, can solve the problems of low bioavailability, high price, poor absorption, etc., and achieve the effects of excellent formulation characteristics, good stability and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

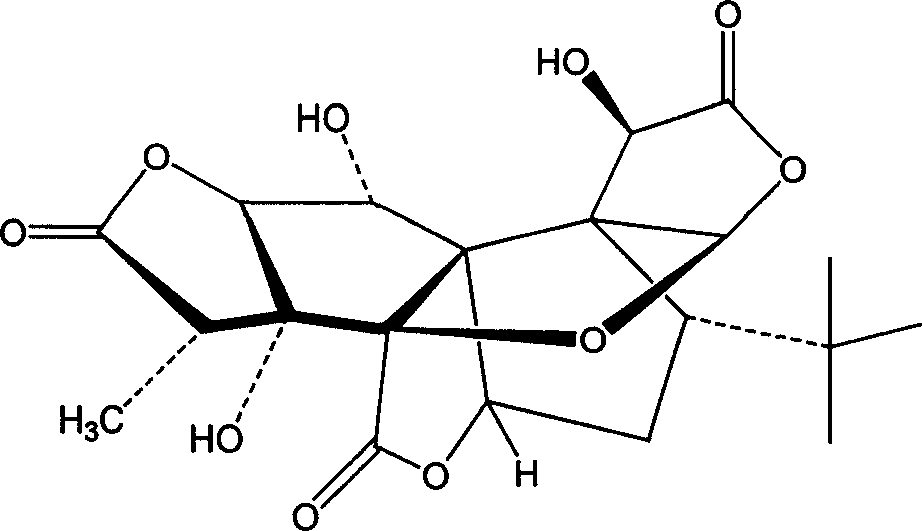

Image

Examples

Embodiment 1

[0054] Put 20g of soybean oil into the container after filtering it with a membrane filter, put 175mg of ginkgolide B into the container, stir mechanically at high temperature (200°C) until the drug is dispersed, then cool down to 95°C, put in 2g of soybean lecithin, and continue to stir mechanically until the drug is dispersed. Dissolve the phospholipids, mix well, and form a mixed solution; put 80ml of water for injection into another container, heat to 95°C, add surfactants, 4.0g of soybean lecithin, 3.5g of polysorbate 80, stir and disperse, adjust the isotonicity Glucose 2.5g, solubilizer dextran 4g, dissolved in water, filtered with a membrane filter, added therein.

[0055] Pour the water phase into the mixed oil phase under stirring again, then disperse at a high speed at 95°C and stir mechanically for 3 hours to make colostrum, adjust the pH to 7.5 with 0.1M sodium hydroxide solution, and transfer the prepared colostrum into High-pressure homogenizer, secondary homoge...

Embodiment 2

[0059] (1) 10g of soybean oil for injection is filtered through a micromembrane filter and put into the container. Ginkgolide B150mg is also put into the container, heated to 50°C and stirred evenly. Add 2.0g of soybean lecithin and continue to stir mechanically to make the mixture uniform. A mixture is formed. (2) Add 90ml of water to another preparation container, heat to 50°C, add 3.0g of soybean lecithin and 3.5g of polysorbate 80 as surfactants and stir to disperse. Glucose 2.5g and dextran 4.5g were dissolved in water, filtered through a micromembrane filter and added to the container. (3) Pour the water phase obtained in step (2) into the mixed phase obtained in step (1) under stirring, disperse at a high speed at 50°C, and stir mechanically for 2 hours to make colostrum, and oxidize it with 0.1M hydrogen The sodium solution adjusted the pH to 7.4. The uniformly dispersed emulsion is filtered through a micromembrane and then emulsified twice through a high-pressure ho...

Embodiment 3

[0061] (1) 25g of soybean oil for injection is filtered through a micromembrane filter and put into the container, and 100mg of ginkgolide B is also put into the container, heated to 50°C and stirred evenly, then 50mg of α-tocopherol is added, and mechanical stirring is continued to make the mixture evenly, A mixture is formed. (2) Add appropriate amount of water to another preparation container, heat to 50°C, add 2.0 g of soybean lecithin and 3.0 g of Pluronic F-68 and stir to disperse. Glycerin 3.0g was dissolved in water, filtered through a micromembrane filter and added to the container. (3) Pour the water phase obtained in step (2) into the mixed phase obtained in step (1) under stirring, disperse at a high speed at 50° C., and then mechanically stir for 2 hours to prepare colostrum. The uniformly dispersed emulsion is filtered through a micromembrane and then emulsified twice through a high-pressure homogenizer. Add water to 100ml under stirring, adjust PH to check the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com