Method for treating leak oil polluted quartz beach sand

A quartz and sand technology, applied in the field of quartz beach sand treatment, can solve the problems of unsatisfactory treatment effect, bad working conditions, high labor intensity, etc. The effect of shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Sand grains polluted by light oil A (the <200°C fraction accounts for 16.5%), with an oil content of 10%, and a weathering period of 3 days.

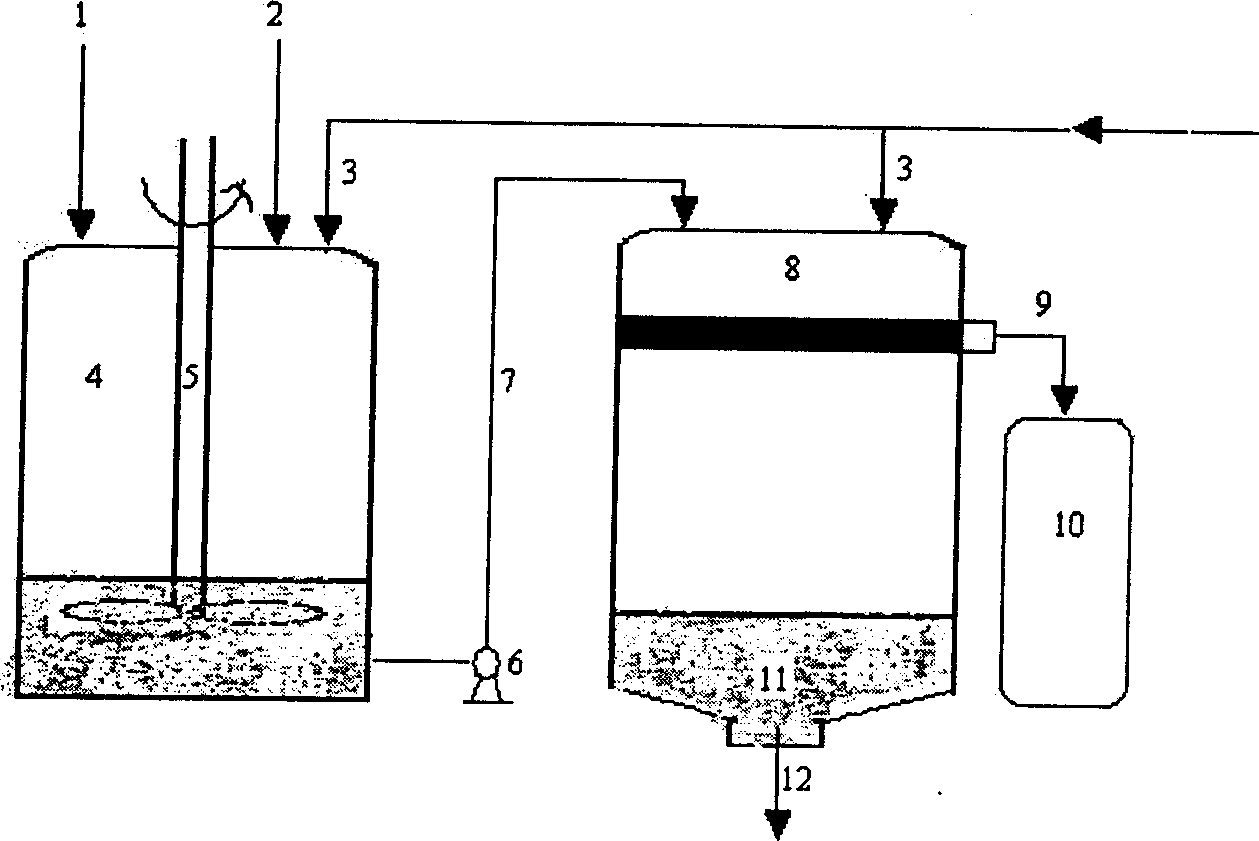

[0022] Treatment method: Combined with the accompanying drawings in the manual, add the quartz beach sand 1 polluted by the oil spill, the medicament 2 required for the separation process, and an appropriate amount of seawater 3 into the premix tank 4. In the premix tank, there is a mechanical stirring device 5, Properly stir the added seawater, chemicals and oil sands. Then add the premixed seawater, medicament and oil sand mixture 7 into the separation tank 8 through the pump 6, and add an appropriate amount of seawater into the separation tank, and the separated oil floats to the upper overflow port 9 of the separation tank and enters the oil collection tank 10 , the washed sand 11 is discharged from the sand outlet 12 at the bottom of the separation tank.

[0023] At a room temperature of about 25°C, 12.11% of the quartz bea...

Embodiment 2

[0025] Sand grains polluted by highly pouring crude oil B, with an oil content of 10%, and a weathering period of 11 days.

[0026] Processing method is with embodiment 1.

[0027] The freezing point of crude oil B is 32°C. Under the condition of room temperature 25 ℃, the quartzy beach sand (water content 0-90% in the sand, oil content 10%) that the degree of weathering reaches 8.19% of crude oil B pollutes, after 11 days of weathering, by adding oil sand weight 1.7 % of alkylphenol polyoxyethylene ether, and 0.1% of carboxymethyl cellulose and 0.1% of water glass by weight of oil sand, add appropriate amount of seawater, soak in the premix tank for about 1 hour, and then carry out mechanical stirring for 30 minutes, and the oil The removal rate can reach 99%.

Embodiment 3

[0029] Sand grains polluted by highly viscous crude oil C, the oil content is about 10%, and the weathering period is 5 days.

[0030] Processing method is with embodiment 1.

[0031] Crude oil C has a viscosity greater than 4000 centipoise at 25°C. At a room temperature of about 25°C, 8.49% of crude oil C polluted quartz beach sand (water content in the sand is 0-90%, oil content is about 10%) can be weathered by adding oil sand after 5 days of weathering 1.7% by weight of alkylphenol polyoxyethylene ether, and 0.2% by weight of oil sands of sodium carbonate, 0.1% by weight of water glass and 0.1% by cyclodextrin, add an appropriate amount of seawater, then soak in the premix tank for about 4 hours, After mechanical stirring for 20 minutes, the oil removal rate can reach 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com