Light source apparatus and fabrication method thereof

A technology of a light source device and a manufacturing method, which is applied to components of lighting devices, projection devices, lighting devices, etc., can solve problems such as attenuating infrared rays, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described in detail.

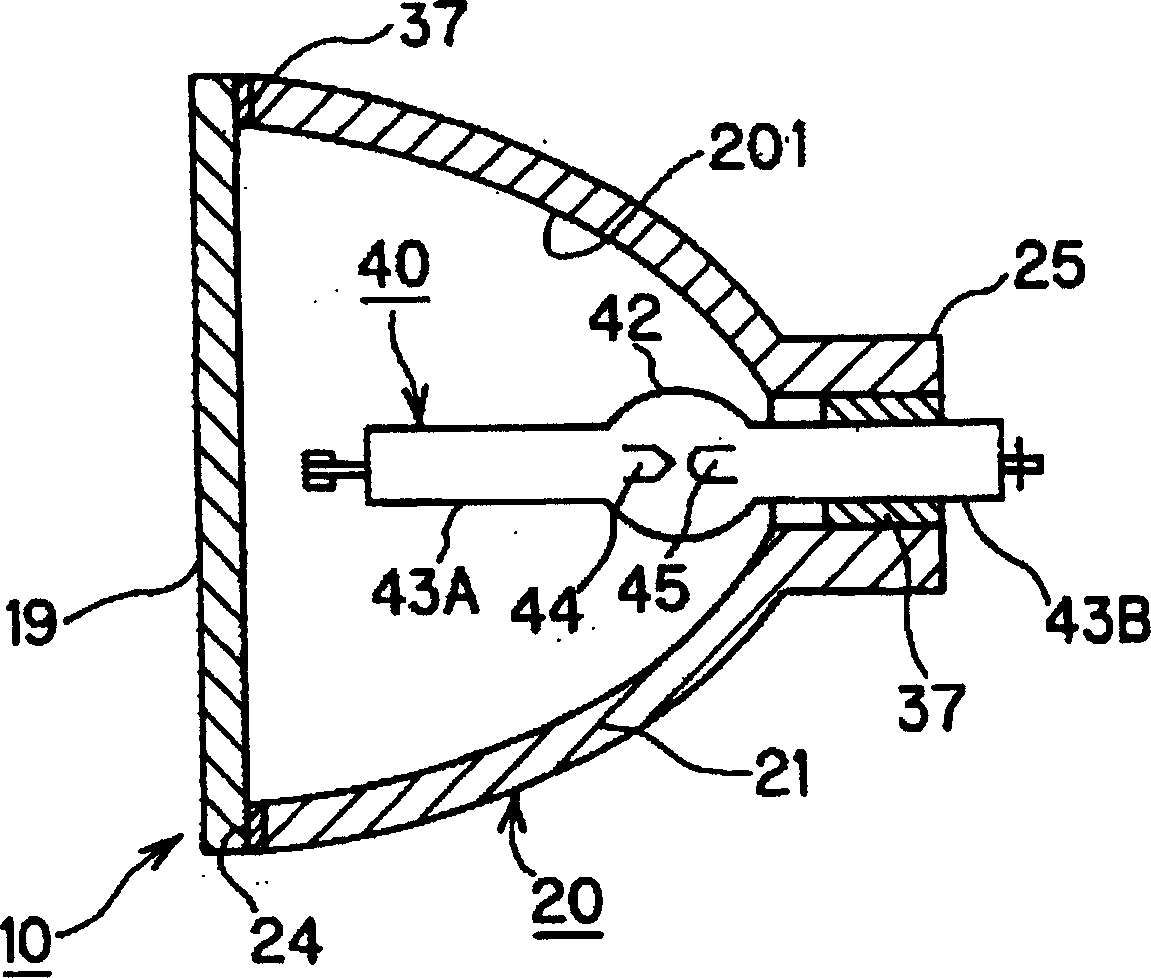

[0036] figure 1 It is an explanatory cross-sectional view showing an example of the structure of the light source device of the present invention.

[0037] The light source device 10 is provided with a high pressure mercury discharge lamp 40 as a light source, a concave mirror that accommodates the high pressure mercury discharge lamp 40 and reflects the radiated light emitted from the high pressure mercury discharge lamp 40 to project the reflected light through an opening. 20, and a translucent front glass 19 provided so as to block the opening of the concave mirror 20, and a high pressure mercury discharge lamp 40 is accommodated in the space formed by the concave mirror 20 and the front glass 19, and also It has a so-called closed structure.

[0038] like figure 1 As shown, the light source device 10 is used in a state where the tube axis of the high pressure mercury discharge lamp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com