Method for producing sulfuric acid utilizing phosphogypsum slag

A production method, phosphogypsum technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the three wastes pollution and other problems, achieve significant economic benefits, significant environmental protection social benefits, and solve the effect of waste residue pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

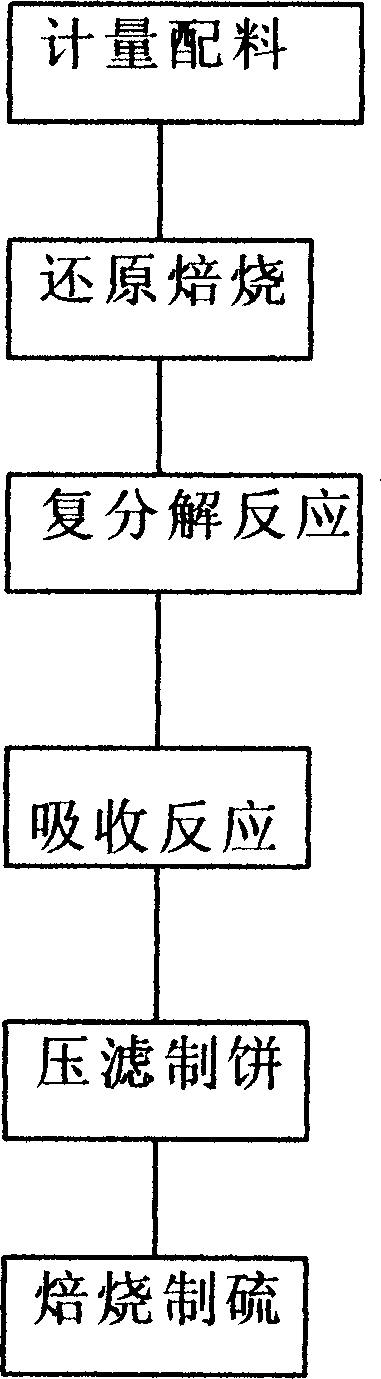

Image

Examples

Embodiment 1

[0024] Utilize the phosphogypsum waste residue that the present invention proposes to produce the production method of sulfuric acid, it carries out by the steps of following order successively:

[0025] (1) metering batching: each reaction raw material is counted as by weight:

[0026] Phosphogypsum waste residue 1 part,

[0027] Coal 0.25 parts,

[0028] Send the weighed raw materials into the pulverizer for crushing to make a mixed material.

[0029] (2) Reduction roasting: send the prepared mixed material into the converter for reduction roasting reaction, control the temperature in the roasting furnace to be 1000°C, and carry out reduction roasting for 15 minutes under the condition of stirring and stirring. The reduction roasting reaction equation is as follows:

[0030]

[0031] Generate calcium sulfide CaS and carbon dioxide flue gas,

[0032] (3) Metathesis reaction: Send the calcium sulfide CaS obtained by reduction roasting into t...

Embodiment 2

[0043] It proceeds through the steps in the following order:

[0044] (1) metering batching: each reaction raw material is counted as by weight:

[0045] Phosphogypsum waste residue 1 part,

[0046] Coal 0.15 parts,

[0047] Send the weighed raw materials into the pulverizer for crushing to make a mixed material.

[0048] (2) Reduction roasting: send the prepared mixed material into the converter for reduction roasting reaction, control the temperature in the roasting furnace to be 800°C, and carry out reduction roasting for 10 minutes under the condition of stirring and stirring. The reduction roasting reaction equation is as follows:

[0049]

[0050] Generate calcium sulfide and carbon dioxide flue gas,

[0051] (3) Metathesis reaction: Send the calcium sulfide obtained by reduction roasting into a pulverizer for pulverization, and send water into the reaction tank according to 2 times the weight of calcium sulfide, and add acetic acid (as ...

Embodiment 3

[0062] It proceeds through the steps in the following order:

[0063] (1) metering batching: each reaction raw material is counted as by weight:

[0064] Phosphogypsum waste residue 1 part,

[0065] Coal 0.35 parts,

[0066] Send the weighed raw materials into the pulverizer for crushing to make a mixed material.

[0067] (2) Reduction roasting: send the prepared mixed material into the converter for reduction roasting reaction, control the temperature in the roasting furnace to be 1200° C., and carry out the reduction roasting reaction for 20 minutes under the working condition of stirring. The reduction roasting reaction equation is as follows:

[0068]

[0069] Formation of calcium sulfide CaS and carbon dioxide CO 2 flue gas,

[0070] (3) Metathesis reaction: Send the calcium sulfide CaS obtained by reduction roasting into the pulverizer for pulverization, and send water into the reaction tank according to 4 times the weight of calcium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com