Preparation of calcium carbonate by microbe deposition

A technology of calcium carbonate and microorganisms, which is applied in the field of preparation of calcium carbonate by microbial deposition, can solve the problems of frequent shortage of resources, insufficient product grades, complex processes, etc., and achieve the effect of abundant resources, low cost and clean environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing calcium carbonate by microbial deposition, inoculating the strain Bacillus pasteurii on a medium containing a urea-containing substrate, carrying out shaking culture at 25-37°C, and controlling the initial pH at 6.0-8.0 , cultivated for 12 to 24 hours, took out the bacterial solution, and mixed with CaCl 2 Solution, finally, take out the precipitate, filter and dry to obtain calcium carbonate. In this embodiment, the temperature of shaking culture can be selected at 25, 30 or 37 °C, and the initial pH is controlled at 6.0, 7.0 or 8.0. The time can be selected from 12, 15, 17, 20 or 24 hours. In addition, in this embodiment, the bacteria liquid taken out can be heated to 50°C-70°C (such as: 50°C, 70°C, 55°C or 60°C), and CaCl can be added at 50°C-70°C 2 solution; this embodiment can also be mixed with CaCl at room temperature after taking out the bacterial solution 2 solution; present embodiment can also be mixed with the MgSO as nucleating agent...

Embodiment 2

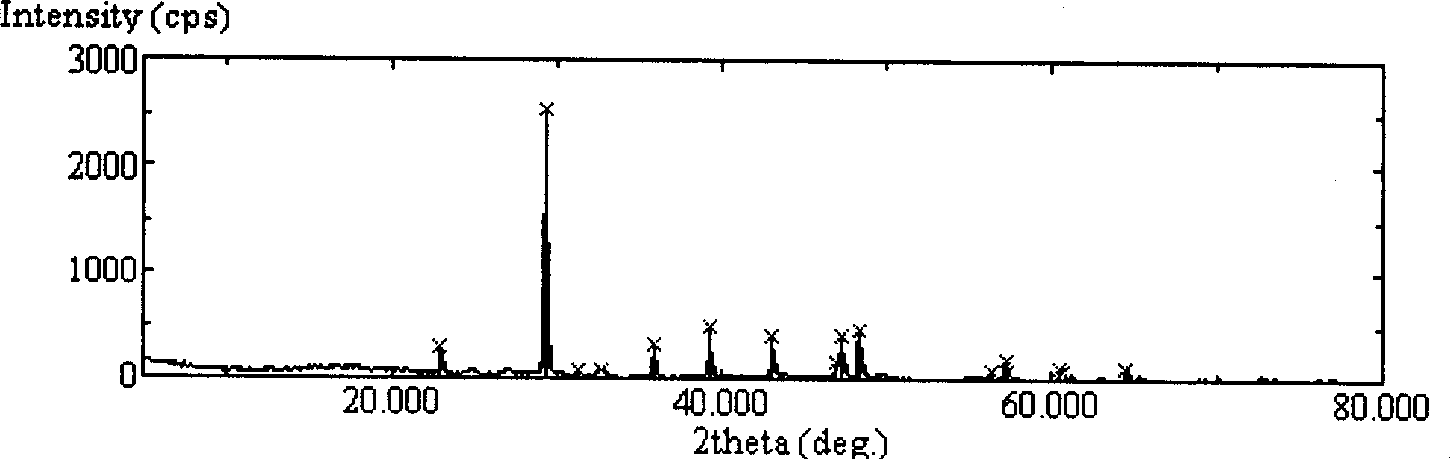

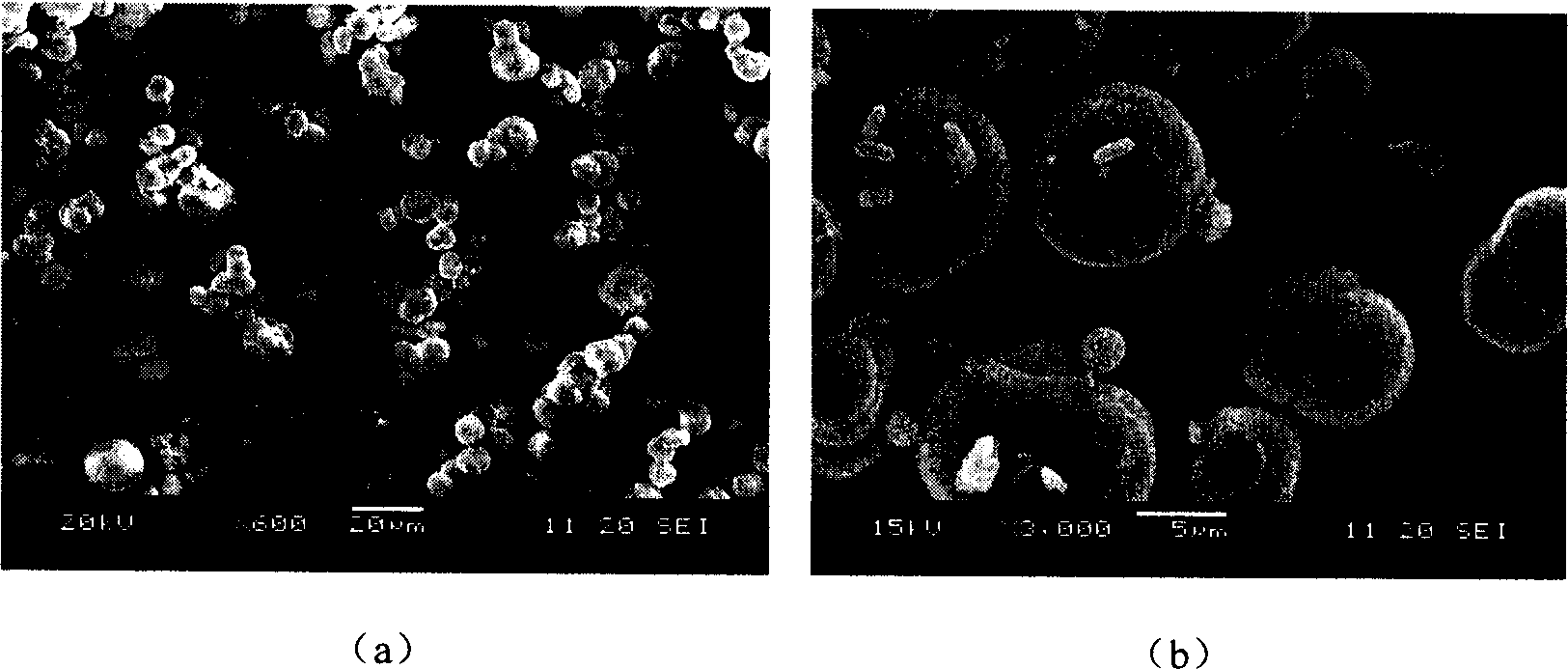

[0022] The strain Bacillus pasteurii was inoculated into the Erlenmeyer flask containing the culture medium (the composition of the culture medium is shown in Table 1), and cultured in a constant temperature shaking incubator at 25-37°C, with the initial pH controlled at 6.0-8.0, and cultured for 12-37°C. Take it out for 24 hours, add CaCl at room temperature 2 Solution, produces precipitation rapidly, it is filtered, dried, and analyzed as calcite type calcium carbonate through X-ray diffraction ( figure 1 ), the purity is very high, and the particle shape is as figure 2 As shown, it is spherical, and residual bacteria are still attached to the surface of the particles.

[0023] Nutrients

Embodiment 3

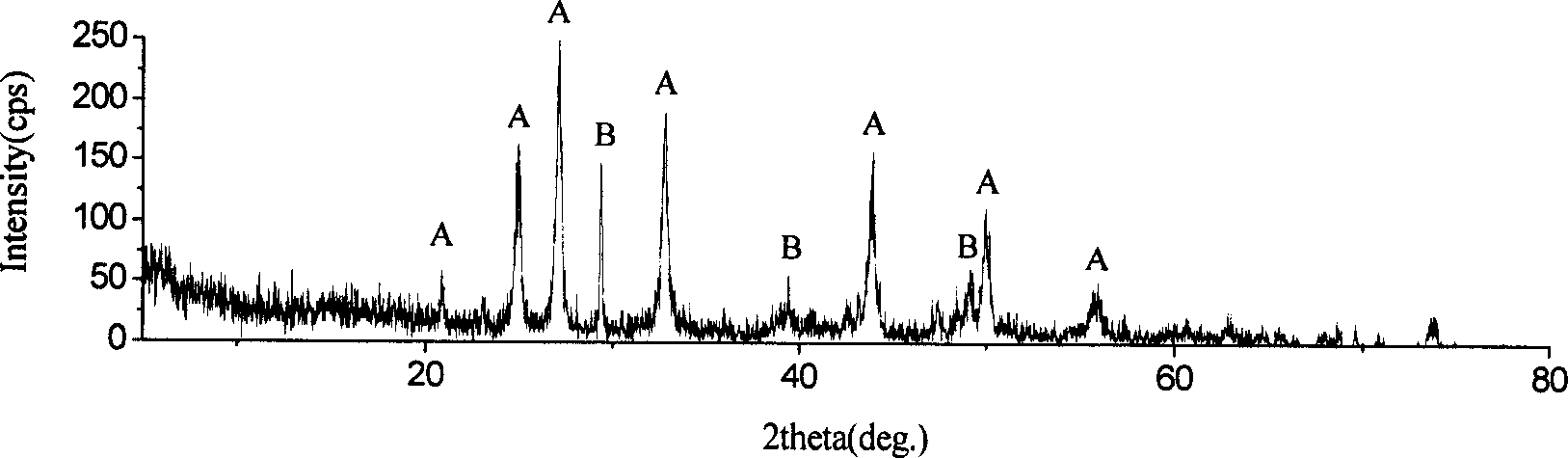

[0025] The strain Bacillus pasteurii was inoculated into the Erlenmeyer flask containing the culture medium (the composition of the culture medium is shown in Table 1), and cultured in a constant temperature shaking incubator at 25-37°C, with the initial pH controlled at 6.0-8.0, and cultured for 12-37°C. Take it out after 24 hours, put it in a constant temperature water bath at 50°C to 70°C, and add CaCl 2 Solution, produces precipitation rapidly, it is filtered, dried, is calcium carbonate through X-ray diffraction analysis, and purity is very high, presents two kinds of crystal forms of vaterite and calcite ( image 3 ), the particle morphology is as Figure 4 As shown, it has various shapes such as spherical, square, and spindle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com