Dampproof Chinese medicine sranular agent and its preparing method

A technology of traditional Chinese medicine granules and traditional Chinese medicine powder, which can be used in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. Properties, overcoming the effect of easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Embodiment 1 prepares the myrrha (system) moisture-proof granule 1000g of optimized adjuvant combination, proportioning

[0107] Take by weighing Myrrha (system) medicinal powder 600g, microcrystalline cellulose 150g, calcium sulfate 120g, pregelatinized starch 80g, calcium hydrogen phosphate 50g cross 80 mesh sieves and mix, moisten soft material with 85% ethanol, pass 24 Make granules through mesh sieve, slowly heat up and dry, granulate, and dry at 60°C until the moisture content is below 3%.

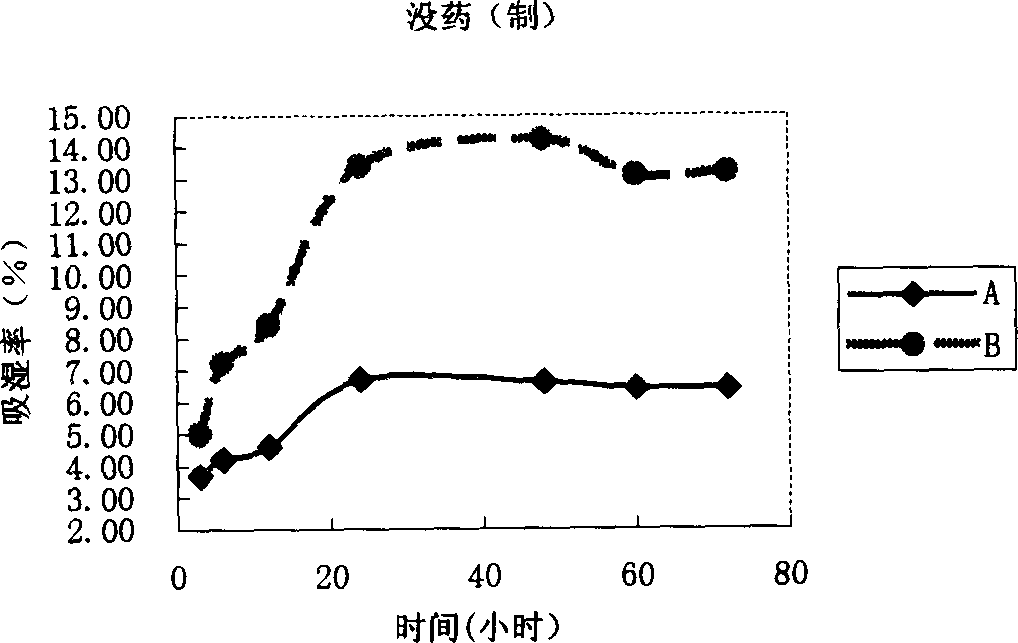

[0108] Attached moisture absorption acceleration experiment comparison chart further illustrates the beneficial performance of the present invention ( figure 1 ):

[0109] Appearance of sample A in accelerated moisture absorption test: good fluidity, dryness, and no color change.

[0110] Appearance of sample B in accelerated moisture absorption test: adhesion, a small amount of particles dissolve, and heavy color difference.

Embodiment 2

[0111] Example 2 Preparation of Polyporus anti-moisture granules 1000g of optimized auxiliary material combination and proportioning

[0112] Weigh 600g of Polyporus medicament powder, 130g of microcrystalline cellulose, 170g of calcium sulfate, 80g of pregelatinized starch, and 20g of calcium hydrogen phosphate, mix through an 80-mesh sieve, moisten the soft material with 85% ethanol, and pass through a 24-mesh sieve The granules are dried by slowly raising the temperature, sized, and dried at 60°C until the moisture content is below 3%.

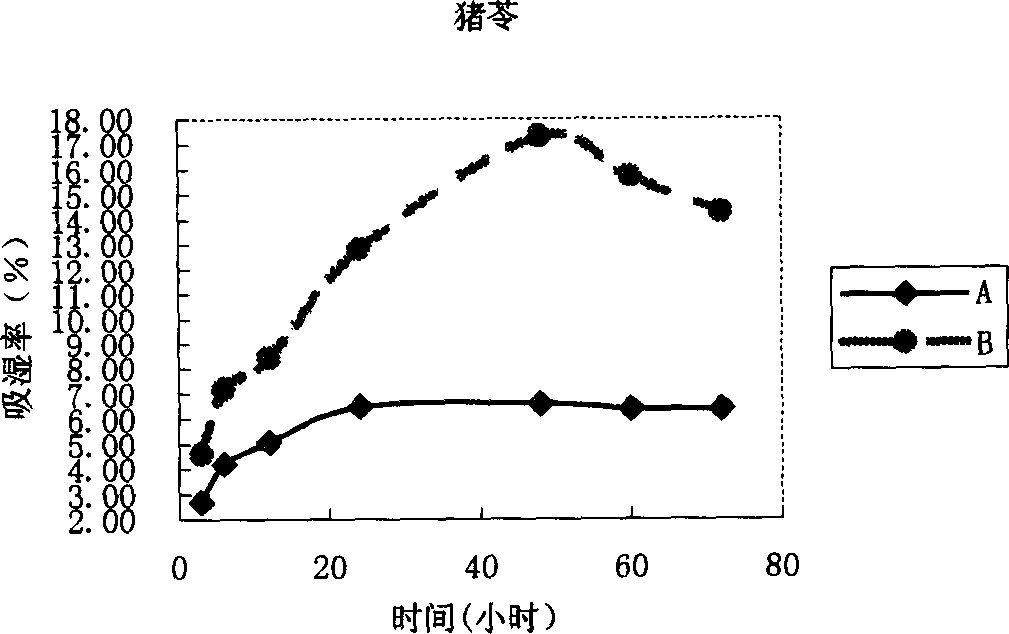

[0113] Attached moisture absorption acceleration experiment comparison chart further illustrates the beneficial performance of the present invention ( figure 2 ):

[0114] Appearance of sample A in accelerated moisture absorption test: good fluidity, dryness, and no color change.

[0115] Appearance of sample B in accelerated moisture absorption test: adhesion, a small amount of particles dissolve, and heavy color difference.

Embodiment 3

[0116] Example 3 Preparation of Zhuru Moistureproof Granules 1000g with Optimized Excipient Combination and Proportion

[0117] Weigh 680g of Zhuru medicinal powder, 200g of microcrystalline cellulose, 70g of calcium sulfate, and 50g of calcium hydrogen phosphate, pass through an 80-mesh sieve and mix evenly, moisten the soft material with 95% ethanol, pass through a 24-mesh sieve to make granules, slowly heat up and dry, Whole grains, dried at 60°C until the moisture content is below 3%.

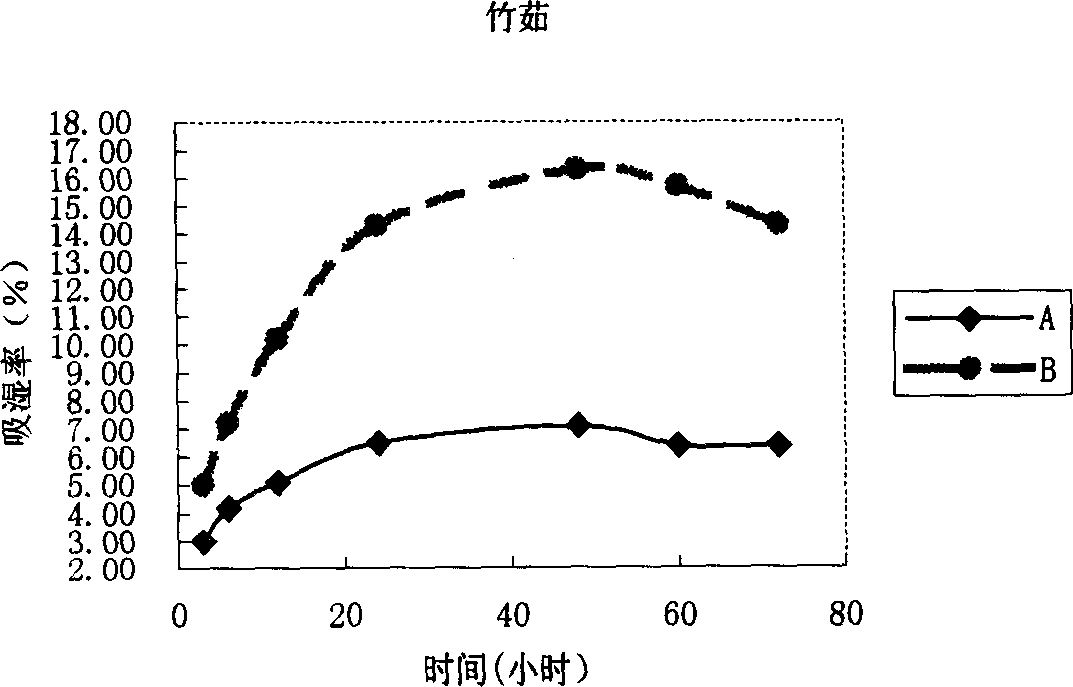

[0118] Attached moisture absorption acceleration experiment comparison chart further illustrates the beneficial performance of the present invention ( image 3 ):

[0119] Appearance of sample A in accelerated moisture absorption test: good fluidity, dryness, and no color change.

[0120] Appearance of sample B in accelerated moisture absorption test: adhesion, partial dissolution of particles, heavy color difference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com