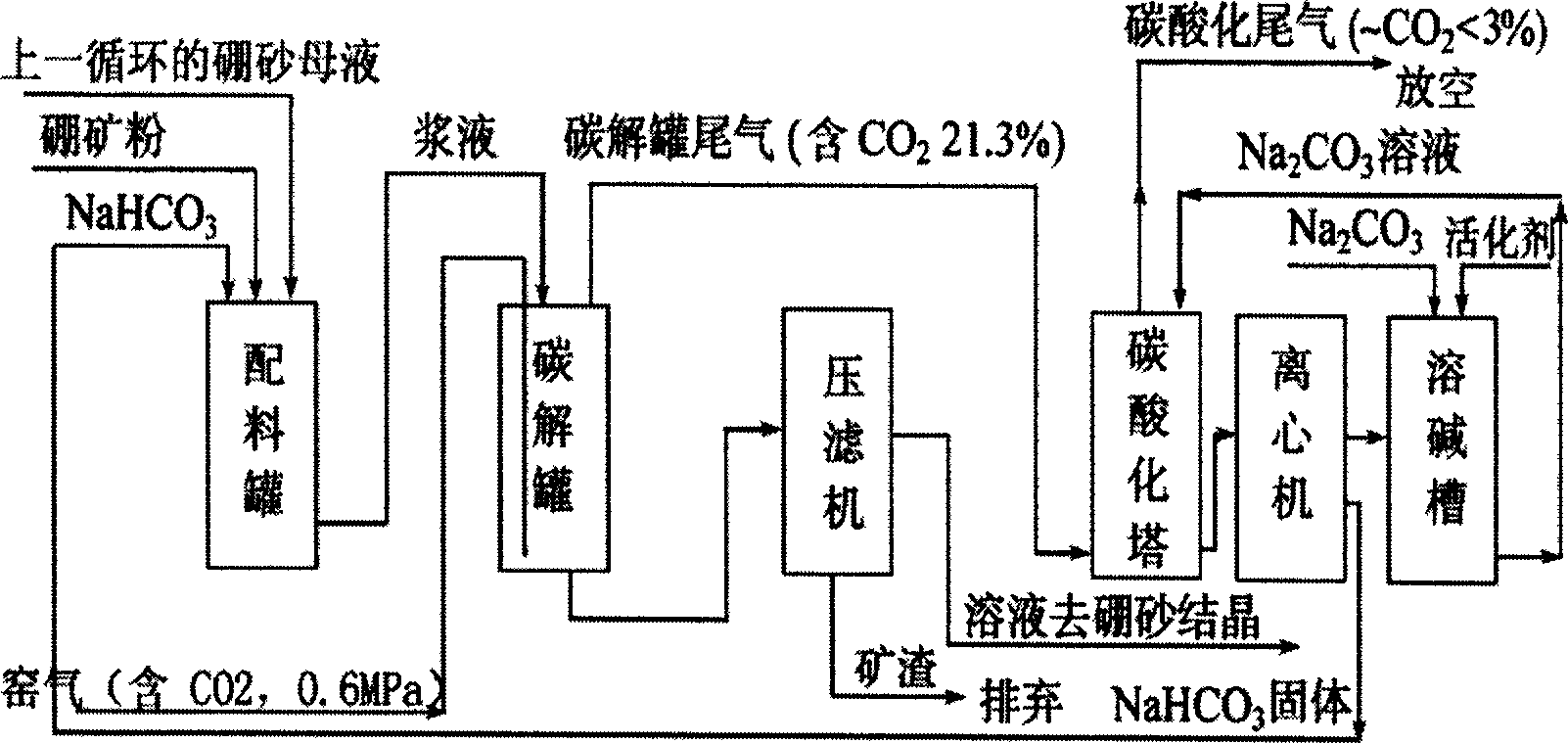

Technology of carbon alkali method for producing borax by adding activator

An activator, carbon-alkali process technology, applied in the field of chemical engineering, can solve the problems of waste of compression work, large amount of difficulty, increasing the number of tanks, etc., and achieve the effect of saving capital construction costs, balancing work, and accelerating decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

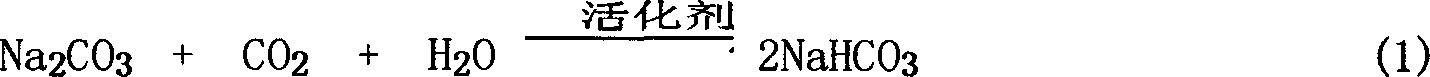

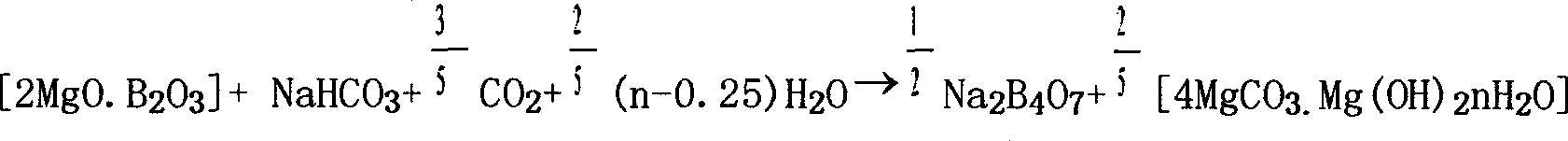

[0026] Contains 13.16% B 2 o 3 3083kg of cooked boron magnesium ore powder and 587kg of NaHCO sent from the centrifuge 3 Use the borax mother liquor of the last cycle to make a slurry, enter the carbonization tank, and feed it with about 30% CO 2 Kiln gas 460m 3 , decompose the boron ore powder, B 2 o 3 The decomposition rate reaches 90%. The pulp is sent to the filter press to filter out the slag, and then 1000kg of borax is crystallized. The borax mother liquor is returned to the carbon solution tank for slurry adjustment. The tail gas from the carbonization tank contains about 21.3% CO 2 , into the carbonation tower from the bottom. Feed at the top of the carbonation tower, containing Na per liter 2 CO 3 178g, NaHCO 3 The solution of 88g and DEA 11g is 2.66m 3 The solution out of the carbonation tower contains Na per liter 2 CO 3 32g, NaHCO 3 99g, and suspended solid NaHCO 3 587g, NaHCO from the carbonation tower 3 After the solution is filtered, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com