Mineralization ecological systen of sludge biological treatment

A biological treatment and ecosystem technology, applied in the field of sludge biological treatment and mineralization ecosystem, can solve problems such as large energy consumption and secondary pollution, and achieve the effects of energy saving, heavy metal reduction and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

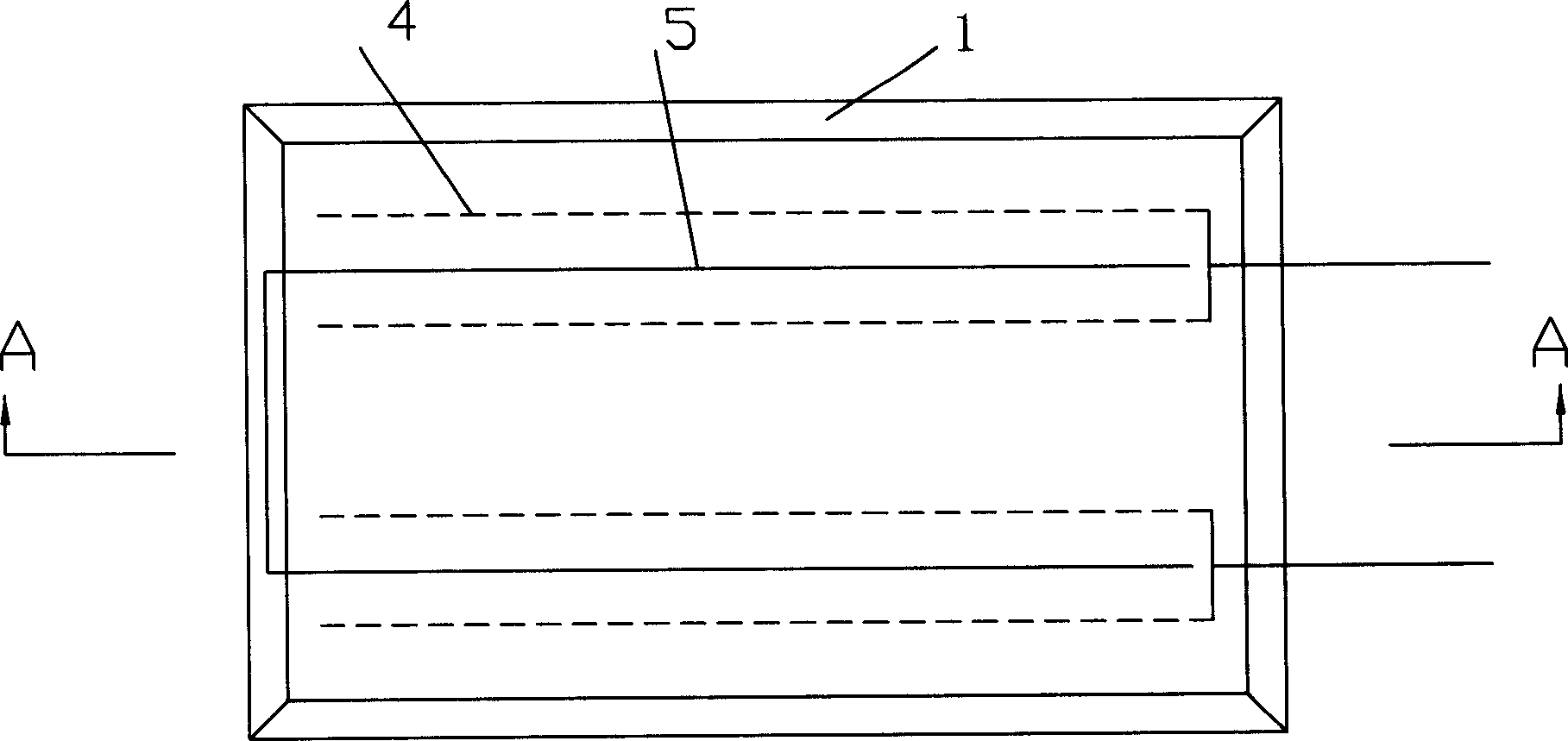

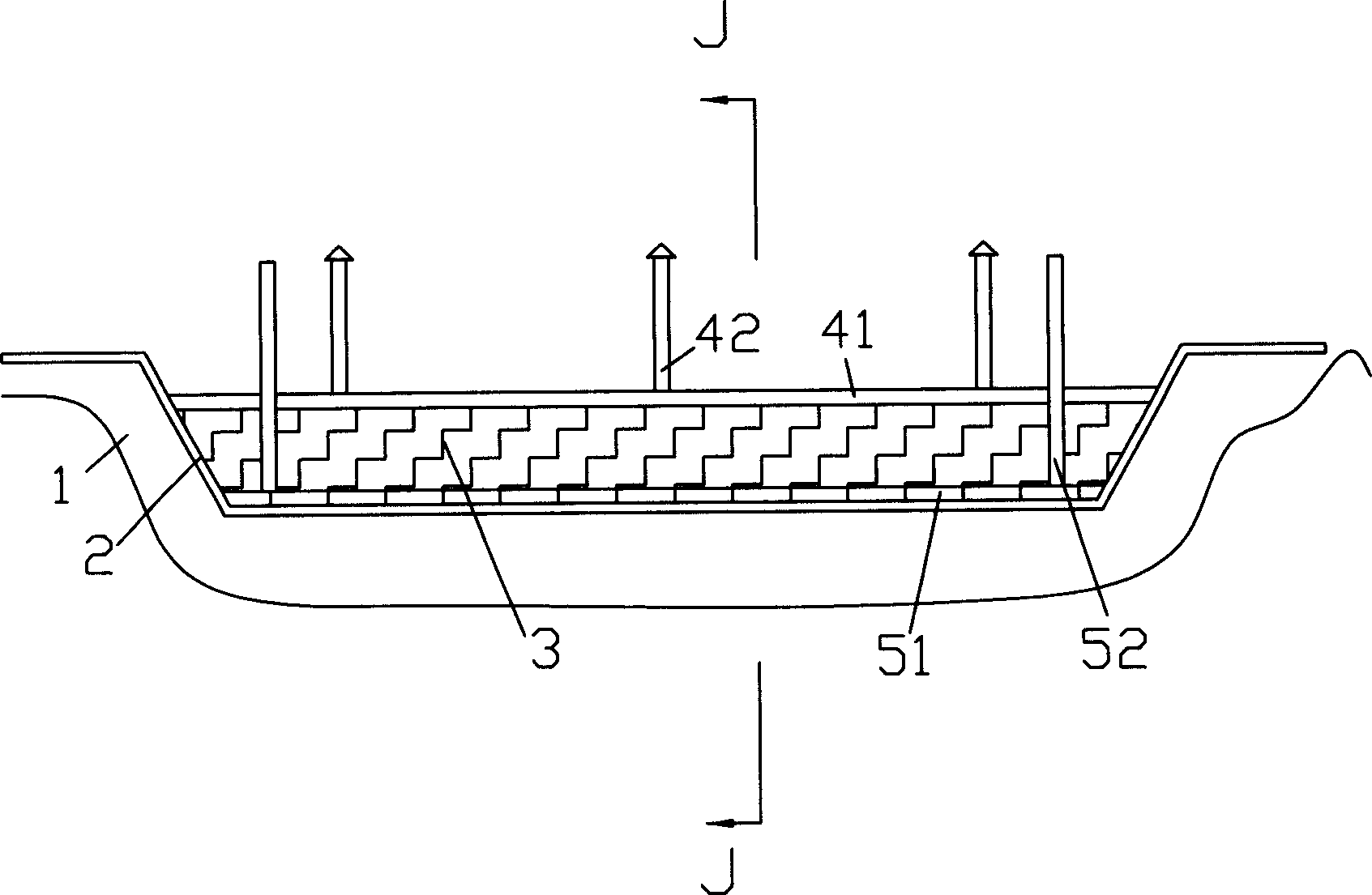

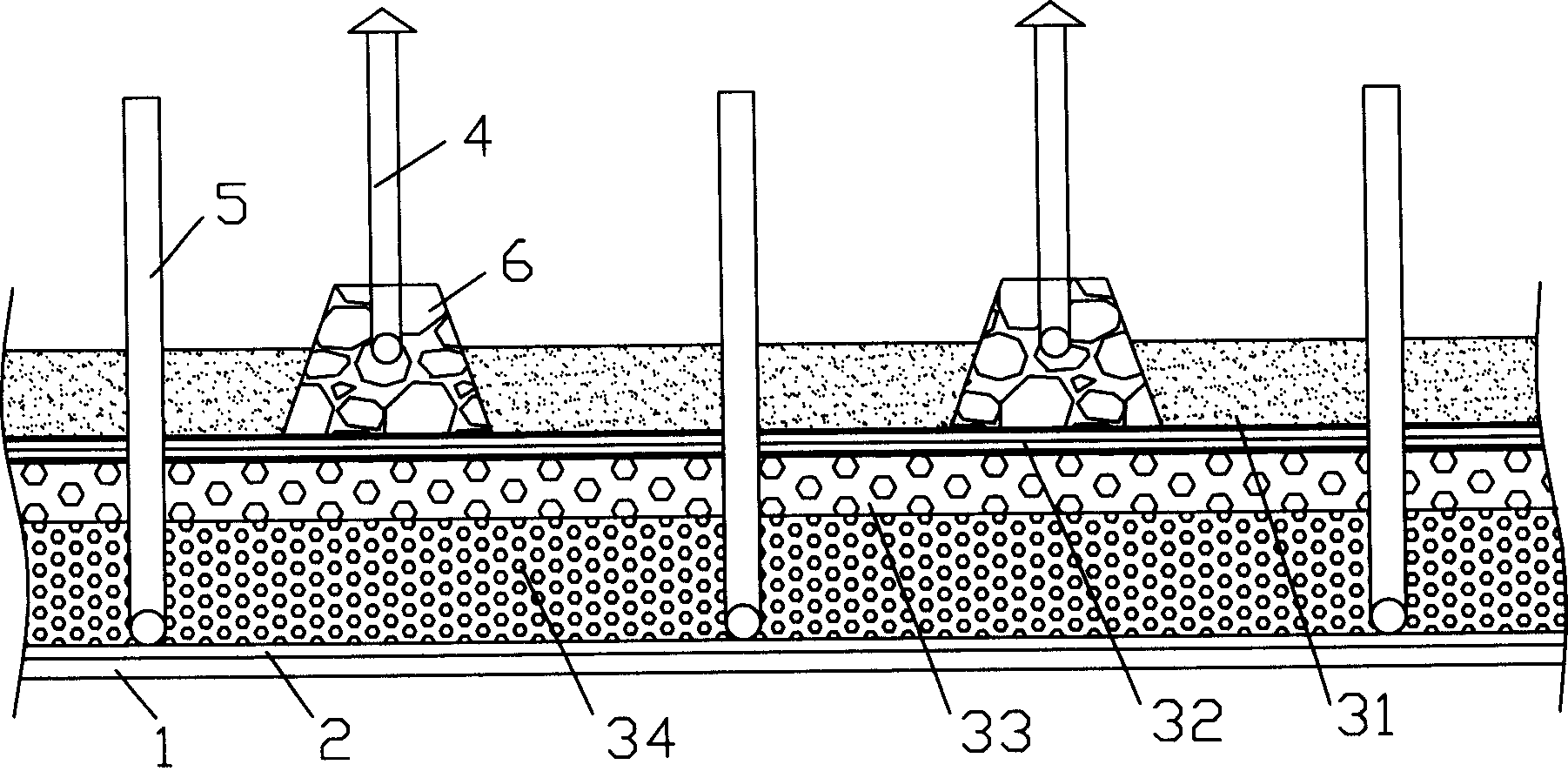

[0022] Such as figure 1 , 2 As shown, the sludge biological treatment mineralization ecological system of the present invention includes a constructed wetland bed 1, which is a pool-like structure with four walls, and its four walls and bottom are provided with a geomembrane waterproof layer 2, and the waterproof layer 2 There is a packing layer 3 on it, such as image 3 As shown, the packing layer 3 includes a coarse river sand and peat mixed layer 31, a straw layer 32, a large-grain gravel layer 33 with a particle diameter of 25-60mm, and small-grained gravel layers with a particle diameter of 13-24mm distributed sequentially from top to bottom. diameter crushed stone layer 34, the thickness of the coarse river sand and peat mixed layer 31 is not less than 160mm, the thickness of the large particle diameter crushed stone layer 33 is 150mm, and the thickness of the small particle diameter crushed stone layer 34 is 380mm; A number of mud input pipes 4 are horizontally laid o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com