Mould kernal of moulded glass lens

A glass lens and mold core technology, which is applied in glass production, glass pressing, glass molding, etc., can solve the problems of high mold core replacement frequency, film peeling, and inability to discharge in time, so as to avoid low production efficiency and long service life The effect of prolongation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

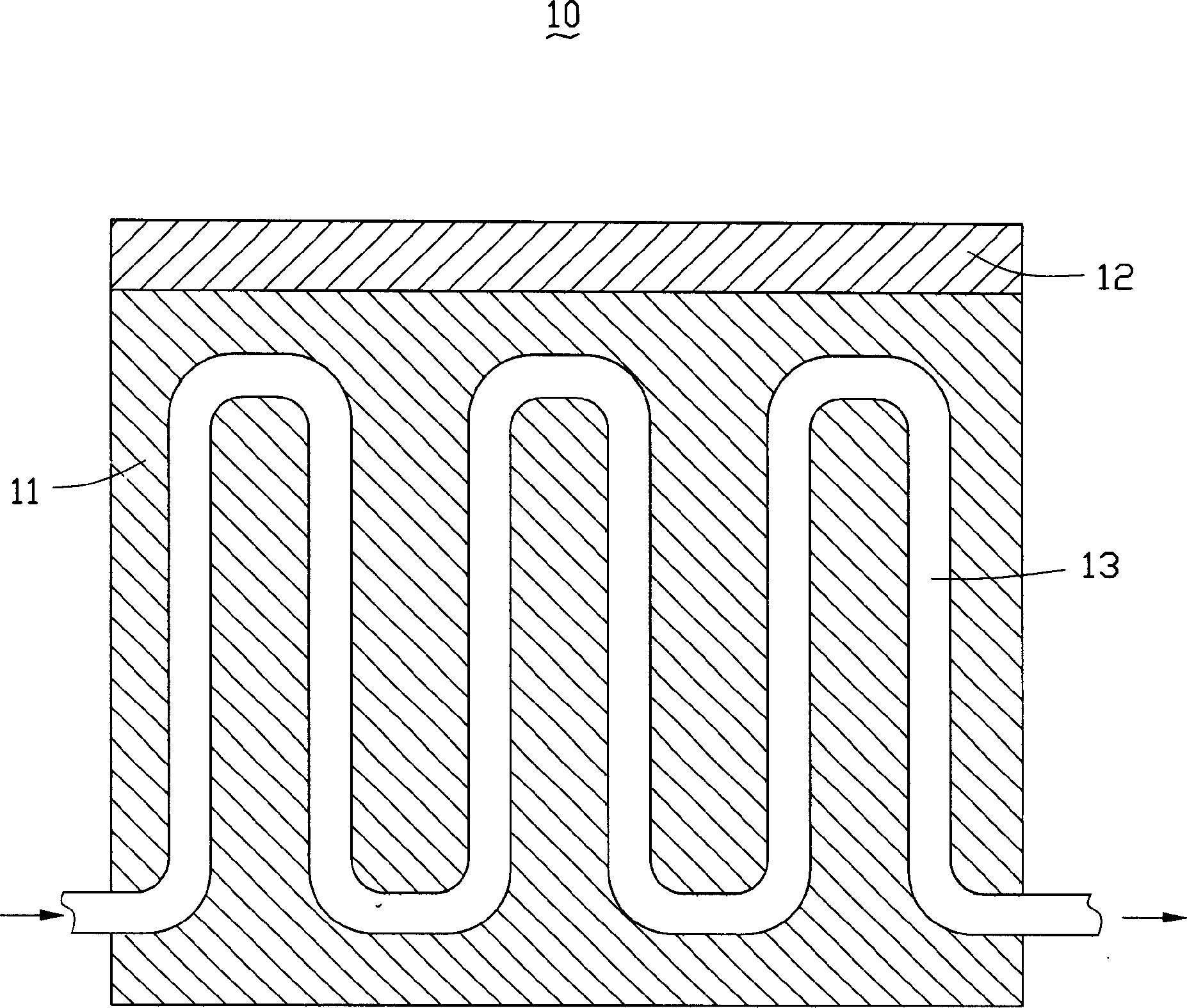

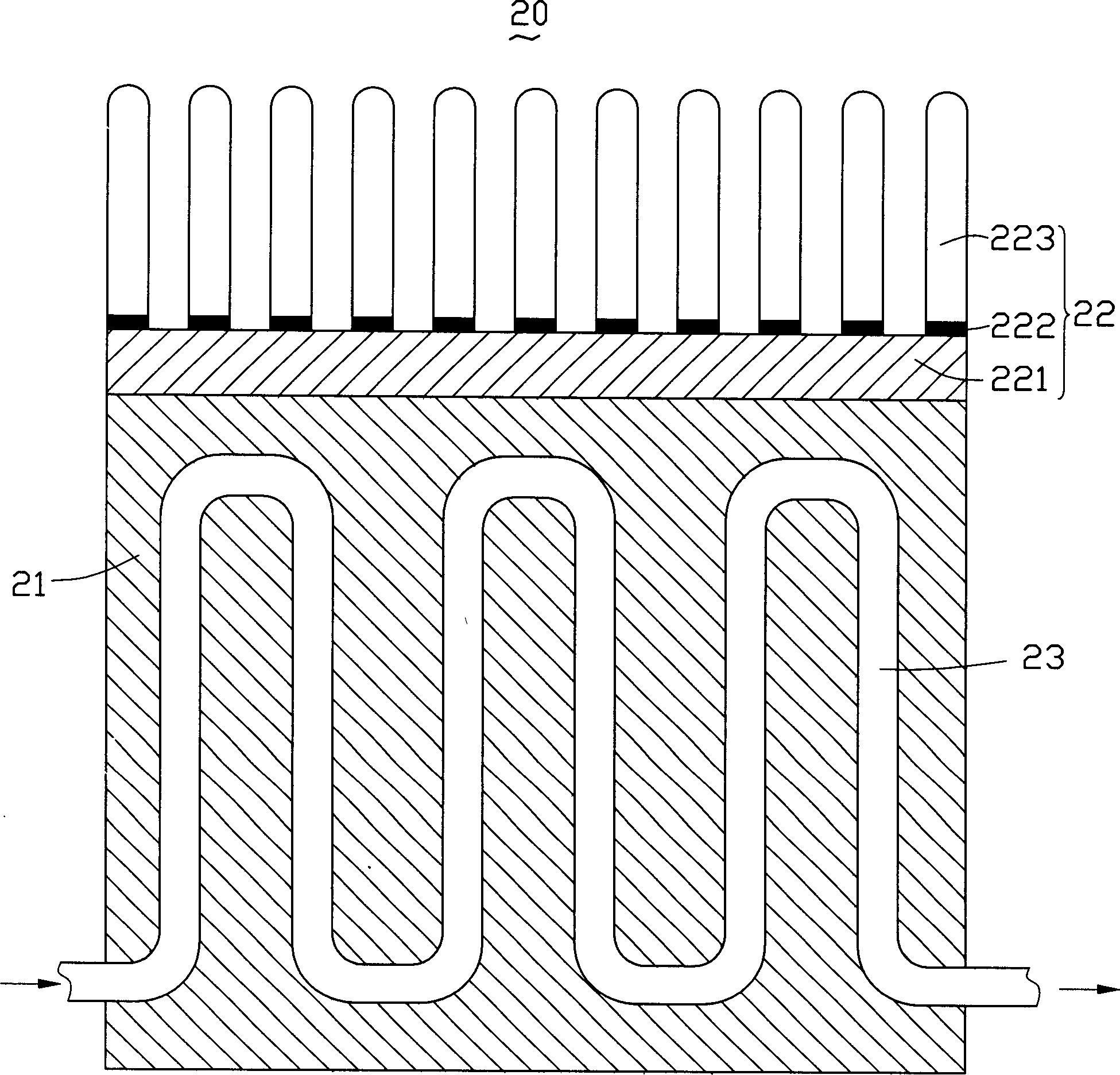

[0026] see figure 1 , is a structural schematic diagram of the first embodiment of the molded glass lens mold core of the present invention. The mold core 10 includes a mold core base 11 with a smooth plane and a coating film 12 covering the smooth plane. The mold core base 11 is made of stainless steel, and its manufacture is to engrave the designed optical geometric shape on the surface of the stainless steel material with an ultra-precision machining machine to make the required shape of the mold core base 11 . In the mold core base 11, a water-cooled heat dissipation pipe system 13 is embedded, and the heat dissipation pipe of the water-cooled heat dissipation system 13 is embedded in the mold core base 11, and bypasses the part of the mold core base 11 close to the coating film 12. To provide good heat dissipation. The coating 12 is Re x -Ir y A multilayer film structure alternately stacked with SiC, the Re x -Ir y Or SiC is deposited on the surface of the mold core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com