Components for substrate processing apparatus and manufacturing method thereof

A substrate processing device and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, plasma, etc., can solve the problems of focusing ring consumption and deformation, and achieve the effect of preventing the decline of operation rate and reducing the particle generation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0066] First, a component for a substrate processing apparatus and a manufacturing method thereof according to a first embodiment of the present invention will be described.

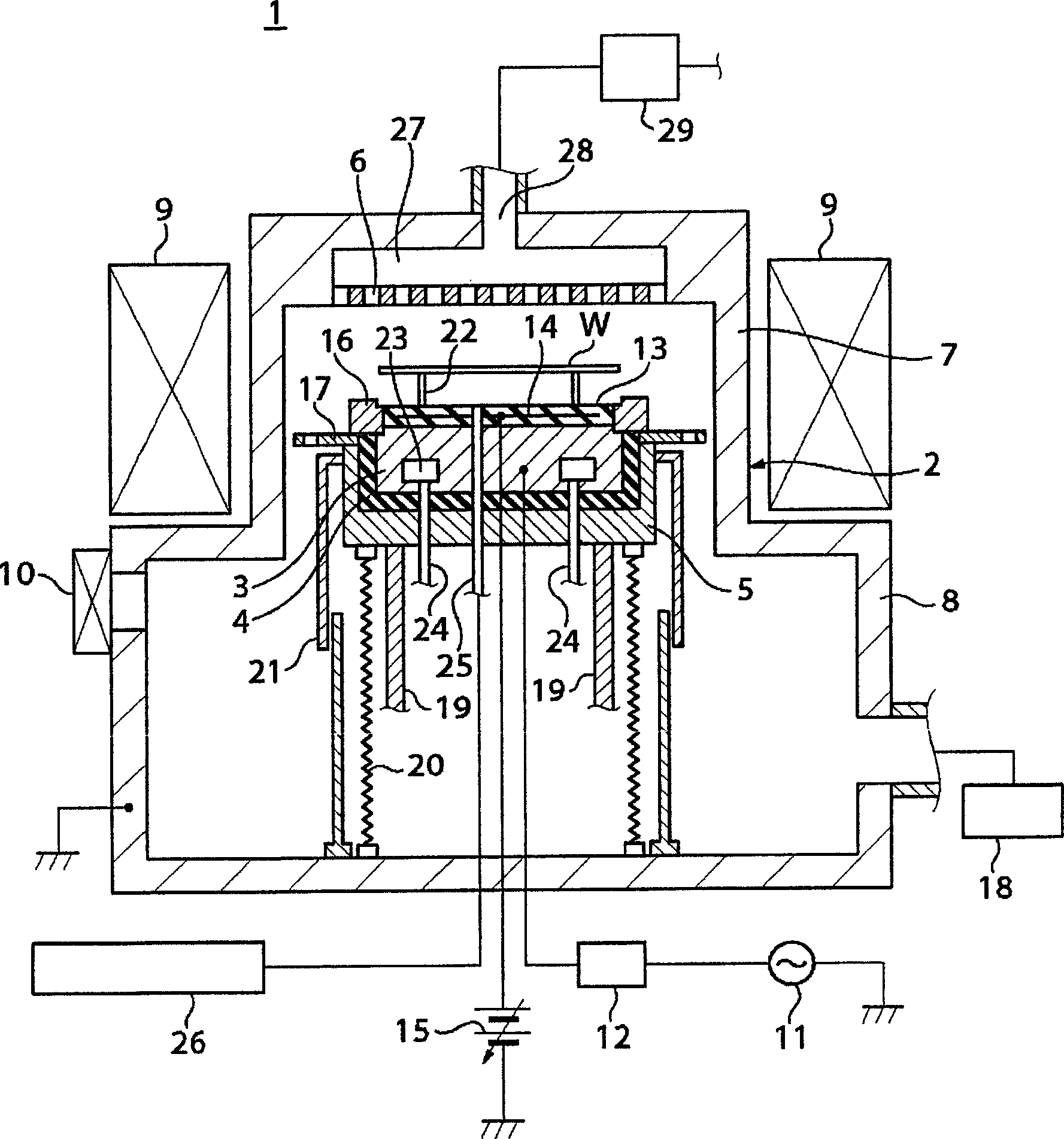

[0067] figure 1 It is a cross-sectional view showing a schematic structure of a substrate processing apparatus using a focus ring as a substrate processing apparatus component according to the first embodiment of the present invention.

[0068] figure 1 Among them, the etching processing apparatus 1 constituted as a substrate processing apparatus has: for example, an aluminum cylindrical chamber 2; The support body 5 of the lower electrode 3 that can be lifted freely; and the shower head 6 that is arranged above the chamber 2 as the upper electrode opposite to the lower electrode 3 .

[0069] The upper part of the chamber 2 is formed as an upper chamber 7 with a smaller diameter, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com