Liquid biological adhesvie using soybean separated protein as base material and production process thereof

A soybean protein isolate and adhesive technology, which is applied in the directions of protein adhesives, adhesives, adhesive types, etc., can solve the problems of difficult product promotion and application, poor water resistance, poor adhesive strength, etc. Improvement of adhesive strength and water resistance, effect of improved adhesive strength and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

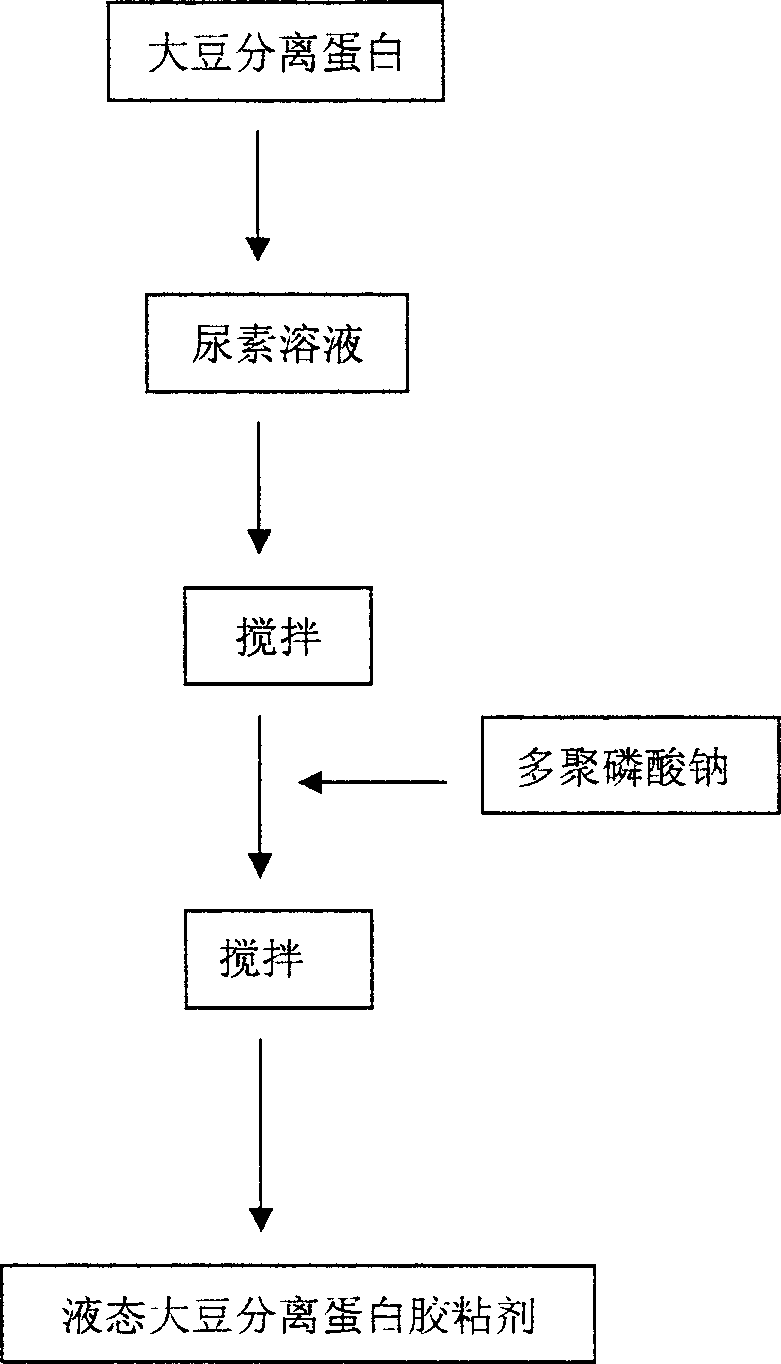

Method used

Image

Examples

Embodiment 1

[0020] In the embodiment of the present invention, the liquid bio-adhesive and production method thereof based on soybean protein isolate, its component ratio is by weight percentage:

[0021] Get soybean protein isolate 9.1%, urea 16.4%, water 72.7%, sodium polyphosphate 1.8% in the embodiment of the present invention. First disperse 16.4% urea in 72.7% water, mix and stir to form a urea solution, then add 9.1% soy protein isolate to the urea solution, stir magnetically at room temperature for 1 hour at a speed of 1100 rpm, then slowly add 1.8 % sodium polyphosphate, continue to react with the same rotating speed stirring for 2 hours, obtain soybean protein isolate adhesive. Stirring equipment selection: 94-2 type timing constant temperature magnetic stirrer.

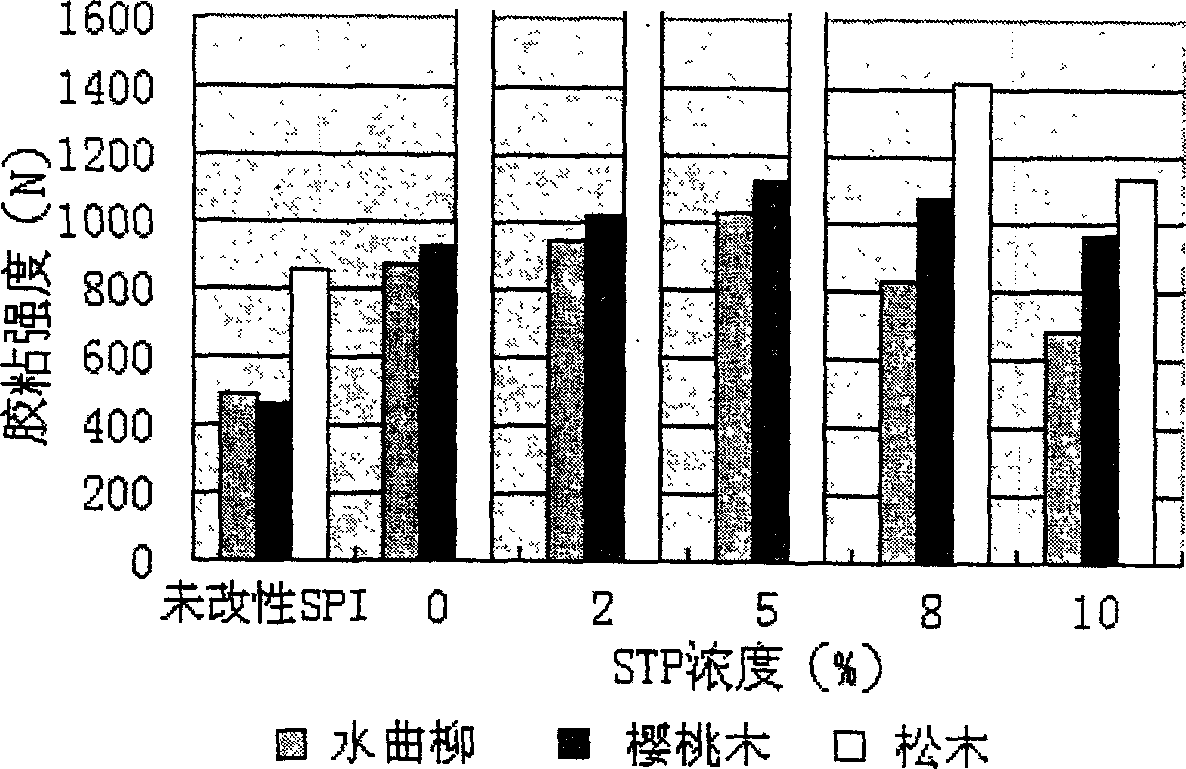

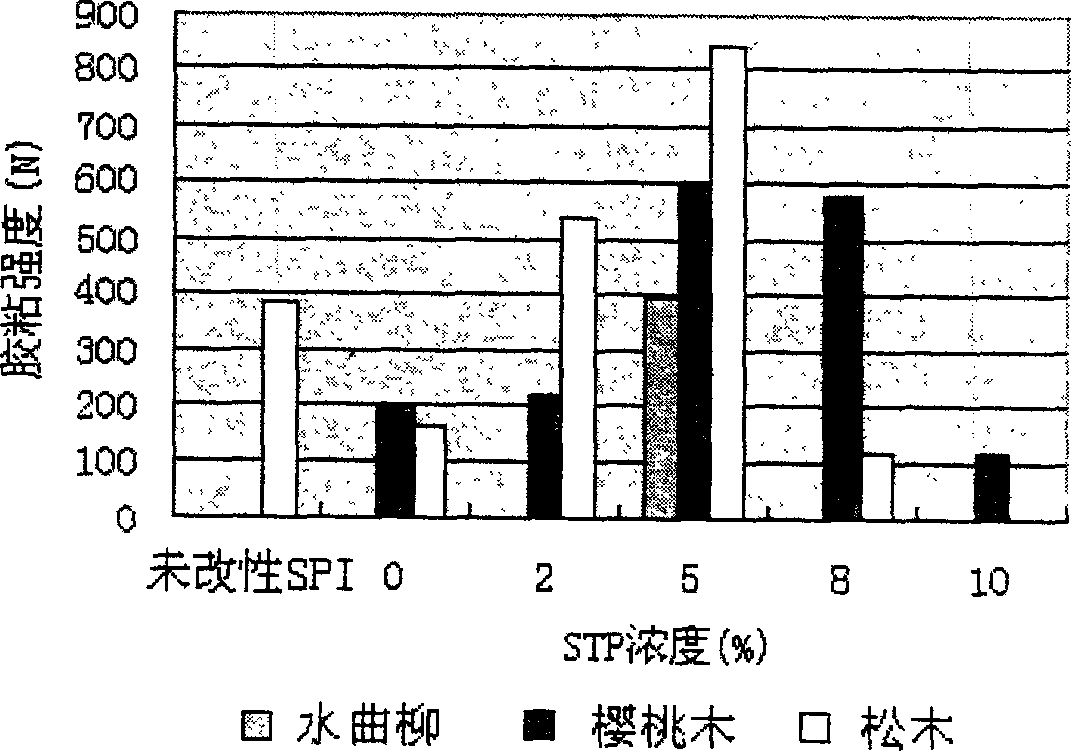

[0022] The adhesive strength and water resistance of the soybean protein isolate adhesive prepared by the embodiment of the present invention are much higher than those of the unmodified soybean protein isolate.

Embodiment 2

[0024] In the embodiment of the present invention, the liquid bio-adhesive and production method thereof based on soybean protein isolate, its component ratio is by weight percentage:

[0025] Get soybean protein isolate 8.9%, urea 15.9%, water 70.8%, sodium polyphosphate 4.4% in the embodiment of the present invention. First disperse 15.9% urea in 70.8% water, mix and stir to form a urea solution, then add 8.9% soy protein isolate to the urea solution, stir magnetically at room temperature for 1.5 hours at a speed of 1150 rpm, then slowly add 4.4 % sodium polyphosphate, continue to react 2.5 hours with above-mentioned same rotating speed stirring reaction, obtain soybean protein isolate adhesive. Stirring equipment selection: 94-2 type timing constant temperature magnetic stirrer.

[0026] The adhesive strength and water resistance of the adhesive obtained by the embodiments of the present invention are the best in all embodiments, much higher than the adhesive strength of u...

Embodiment 3

[0028] In the embodiment of the present invention, the liquid bio-adhesive and production method thereof based on soybean protein isolate, its component ratio is by weight percentage:

[0029] Get soybean protein isolate 8.5%, urea 15.2%, water 67.8%, sodium polyphosphate 8.5% in the embodiment of the present invention. First disperse 15.2% urea in 67.8% water, mix and stir to form a urea solution, then add 8.5% soybean protein isolate to the urea solution, stir magnetically at room temperature for 2 hours, the speed is: 1200 rpm, and then slowly add 8.5 % sodium polyphosphate, continue to react with the same rotating speed stirring for 3 hours, obtain soybean protein isolate adhesive. Stirring equipment selection: 94-2 type timing constant temperature magnetic stirrer.

[0030] The adhesive strength and water resistance of the adhesive obtained by the embodiment of the present invention are slightly worse than those of the first and second embodiments.

[0031] The raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com